Superelasticity And Shape Memory Of Nitinol

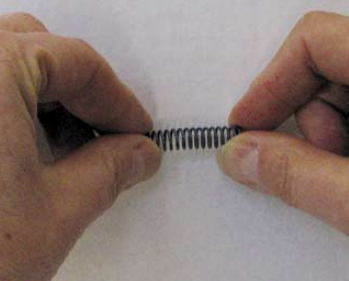

Nickel-Titanium (Nitinol) alloys possess a combination of physical and mechanical properties that make them suitable for manufacturing self-expanding stents. Some currently used materials do not possess these properties. They exhibit elastic deployment, thermal deployment, and buckling resistance. They also show stress retention, dynamic interference, pre-set stiffness, magnetic resonance imaging compatibility, X‑ray visibility, and biocompatibility. The term "shape memory" describes the ability to recover a predetermined shape after plastic deformation. "Superelasticity" refers to the ability to undergo elastic strain that compares with that of medical grade stainless steel.

Nitinol alloys are increasingly used for manufacturing self-expanding stents, transplant support systems, filters, baskets, and various devices for interventional procedures. Nitinol Medical Technologies, World Medical Technologies, and Cordis provide products based on the properties of these alloys. Their elastic deployment and shape memory characteristics are well documented. In combination with strength, fatigue resistance, biocompatibility, and MRI compatibility, these alloys support the development of quality medical devices. Conventional materials such as stainless steel, titanium, and Eigilloy exhibit mechanical behaviour that differs from human tissue. Nickel-Titanium alloys are nearly equiatomic intermetallic compounds of titanium and nickel.

In combination with strength, fatigue resistance, biocompatibility, and MRI compatibility, these alloys support the development of quality medical devices. Conventional metallic materials such as stainless steel, titanium, and Eigilloy exhibit mechanical behaviour that differs from that of human tissue. Similarly, Nickel-Titanium alloys are nearly equiatomic or nearly equiatomic intermetallic compounds of titanium and nickel.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento