The Advantages Of Rotary Targets In Sputtering Applications

When working with sputtering systems, you recognise that not all targets are equivalent. Flat targets may fulfil basic functions, but when high throughput, wide substrates or costly materials are involved, they may not be adequate. In these cases, rotating targets offer improved material utilisation, more consistent film uniformity and extended equipment runtime. This text details the reasons for their use.

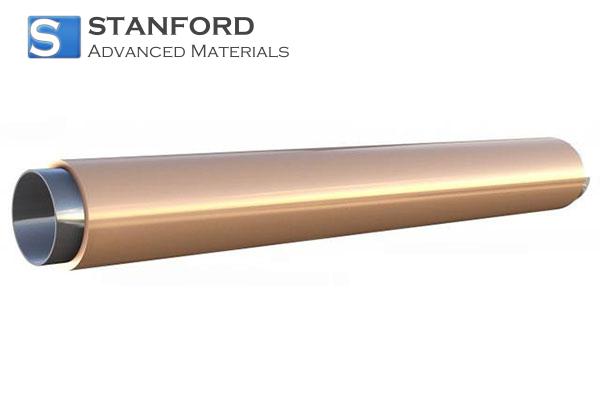

Firstly: What is a Rotating Target?

Rotating targets (or cylindrical rotating targets) are defined by their tube-like structure, usually made of metal, which rotates during the sputtering process. The target material is deposited on the outer surface of the cylinder. As the tube rotates, erosion occurs uniformly around its circumference.

This simple movement eliminates localised erosion typically observed with flat targets. The temperature remains more stable during operation, which is important for high-performance systems. In conjunction with inline or large-area coating equipment, rotating targets perform reliably.

An Improved Structure

Consider the following technical design details:

-

Cylindrical Design → complete 360° erosion; no localised hot spots occur

-

High-Conductivity Bonding Layer → improved thermal management (for example, conductive epoxy is used rather than soft indium)

-

Uniform Rotation → achieved by precise bearings and stable drives

These features result in smoother operation, fewer unexpected issues during use and improved film outcomes overall.

The Actual Advantages of Rotating Targets

1. Increased Material Utilisation

Sputter materials – particularly high-purity materials such as tantalum or molybdenum – are expensive. Flat targets may utilise only 20–30% of their material before being exhausted. Rotating targets can increase the utilisation rate to 70–80% or more, as erosion occurs uniformly around the cylinder.

2. Improved Uniformity

Thickness variations on large substrates are a common issue in some processes. The rotation distributes the sputtered material evenly. This leads to a more consistent coating, which is important for applications in optics, semiconductors and multilayer technologies.

3. Fewer Particles and Defects

Flat targets can develop deep erosion tracks, which may release particles and contaminate the film. Rotating targets show even wear, thereby reducing particle generation and potential defects. This improvement is crucial for applications such as AR coatings, MEMS and OLEDs.

This reduction in contaminants is significant for sensitive processes.

4. Extended Lifespan and Reduced Downtime

Uniform erosion causes slower wear. Consequently, replacement intervals are extended, production halts are fewer and conditions remain stable over lengthy runs.

-

Longer intervals between replacements

-

Fewer production stoppages

-

Stable conditions over long periods

For operations running 24 hours or when higher throughput is required, these advantages alone can justify the change.

5. Suitability for High-Power Processes

High-power sputtering demands effective thermal control. The indium bonding used in some flat targets has a low melting point and can fail under higher temperatures. In rotating targets, high-temperature conductive adhesives are typically used. These adhesives withstand higher loads. Consequently, they are engineered for demanding process conditions.

6. Wide Material Compatibility

Rotating targets are not limited to metals. They are available for:

-

Metal alloys (for example, TiAl, CrZr)

-

Transparent conductors such as ITO

-

Magnetic materials

-

Ceramic composites

This versatility allows their use in applications ranging from solar panels to hard disk drives.

Designed for Large-Area Production

If your production line involves metre-wide glass, continuous materials or simply large substrate areas, rotating targets are appropriate. They integrate with automated handling systems and maintain stable performance during long runs. Flat targets often require more frequent maintenance, which affects production continuity.

Flat targets do not meet the same requirements, as they demand more regular maintenance.

Concluding Considerations

Rotating targets offer a technical upgrade and a strategic operational choice. They provide increased material usage, improved film quality and extended intervals between replacements.

-

More material for your expenditure

-

Improved coating quality

-

Reduced downtime and cleaner operation

Over time, these factors result in lower overall operating costs and fewer production interruptions.

If you are considering the transition or wish to assess the suitability of rotating targets for your application, you should consult a supplier who specialises in these materials.

At Stanford Advanced Materials, we supply rotating targets fabricated from high-purity metals, alloys and high-performance ceramics. Whether sputtering tantalum for semiconductors or ITO for displays, our inventory and technical expertise support your production processes.

Find further details here: https://www.samaterials.co.uk/153-sputtering-targets.html

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento