Titanium Used In Marine Engineering

For materials used in marine technology, high strength is required. They must possess corrosion resistance against hydrothermal fluids, vulcanisation protection, antimicrobial adhesion and high toughness. Titanium is designated as "Ocean metal". It has low weight, high strength and corrosion resistance. It can resist erosion from sea water and the marine atmosphere. Titanium is employed in ship engineering. It is suitable for lightweight ship equipment. It is one of the emerging key materials in marine technology. The applications of Titanium alloys in maritime engineering are detailed below.

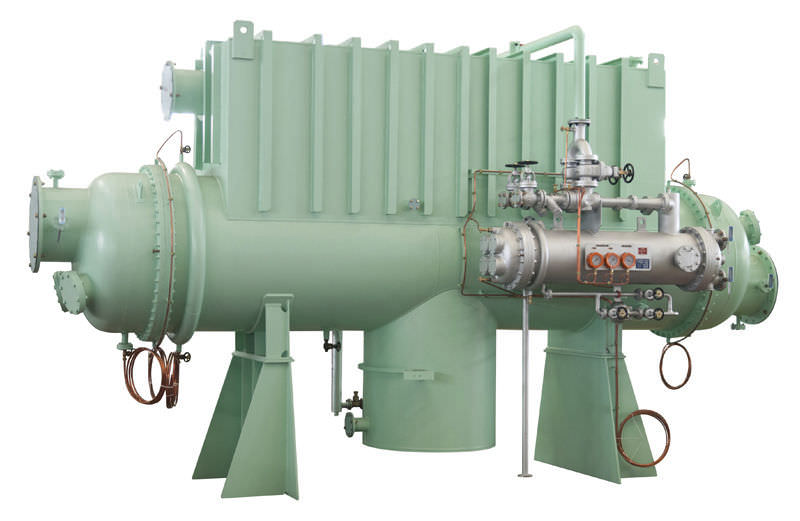

Titanium is used for condensers

Condensers are important equipment in coastal power plants and nuclear power stations. Seawater is used as the cooling medium. Conventional condensers are made from steel and copper alloys. They have limited corrosion resistance and a short operational lifespan. Polluted seawater can cause pitting, crevice corrosion, stress corrosion and fatigue corrosion in copper alloy condensers. These issues may result in leakage and significant economic losses. Studies have demonstrated that Titanium is the most suitable material for power plant condensers. The Titanium condensers in coastal power stations offer enhanced corrosion resistance, an extended operational lifespan, increased heat exchange performance and measurable economic benefits.

Titanium for nuclear submarines

A typical example of Titanium use in maritime applications is the Russian nuclear submarine of the Typhoon class. The submarine employs a Titanium hull. Military requirements demand a double-hull structure. The double hull contains 9 000 tonnes of Titanium. This design lowers the magnetic signature, allows deeper diving, increases speed, reduces noise and decreases maintenance intervals.

Titanium for seawater desalination

Desalination is the primary method of obtaining freshwater in water-scarce regions such as the Middle East. The multi-stage flash evaporation process is widely implemented in seawater desalination. The equipment includes a sea water heater, a heat recovery condenser, a heat rejection condenser, an air-water condenser and a jet compressor. Many heat transfer tubes are used in the heat exchange process. Copper alloy tubes have been replaced by Titanium tubes because copper alloys do not offer sufficient corrosion resistance. The Titanium alloy withstands high-temperature ionic corrosion. It is used extensively in the evaporator sections of seawater desalination plants. It also exhibits high resistance to chlorine, making it the preferred material for heat exchangers.

Offshore drilling platforms

Components made from Titanium alloys in offshore drilling platforms exhibit high strength and low density. They offer adequate corrosion resistance and toughness. These attributes make them suitable for vertical pipes, drill strings and conical tension joints in offshore drilling systems. The combined use of Titanium and steel in composite materials has reduced costs and increased operational efficiency. In recent years, the application of Titanium alloy components in offshore oil drilling systems has increased significantly.

Conclusion

We appreciate your attention to this article. We hope it enhances understanding of the utilisation of Titanium in marine technology. For further information about Titanium products, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of Titanium products. It has over two decades of experience in the production and distribution of Titanium materials. The company supplies products that meet the research and production requirements of its customers. We believe that SAM will be your chosen Titanium supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento