Titanium Used In The Aerospace Industry

Titanium has a lower density than steel. Its stiffness is lower than that of steel, but significantly higher than that of aluminium. These properties make it suitable for many applications. High-performance bicycle frames and golf clubs are manufactured from titanium. Titanium containing 4% aluminium is used for surgical implants such as artificial joints. It is well tolerated by body tissue, resists corrosion and is strong without being overly stiff. This article concerns the use of titanium in the aerospace industry.

Although titanium is a commonly available metal, the development of its alloys only began in the late 1940s. The common ore TiO2 could not be directly reduced with carbon because carbides would form. An indirect chemical process was discovered. Initially, titanium oxide reacts with chlorine gas to form titanium tetrachloride, with carbon removing the oxygen. Then the titanium tetrachloride is reduced with magnesium. High temperatures are required for these reactions. Even after the metal became available, obstacles remained for its application. Molten titanium reacts with atmospheric oxygen or nitrogen. Consequently, new processing methods in inert atmospheres were required to replace traditional forging and machining techniques. Large quantities of oxygen make titanium strips brittle. However, titanium containing 0.3% oxygen is strong and is less pliable than pure titanium. Slightly higher amounts of these elements result in a hard metal suitable for jet engines.

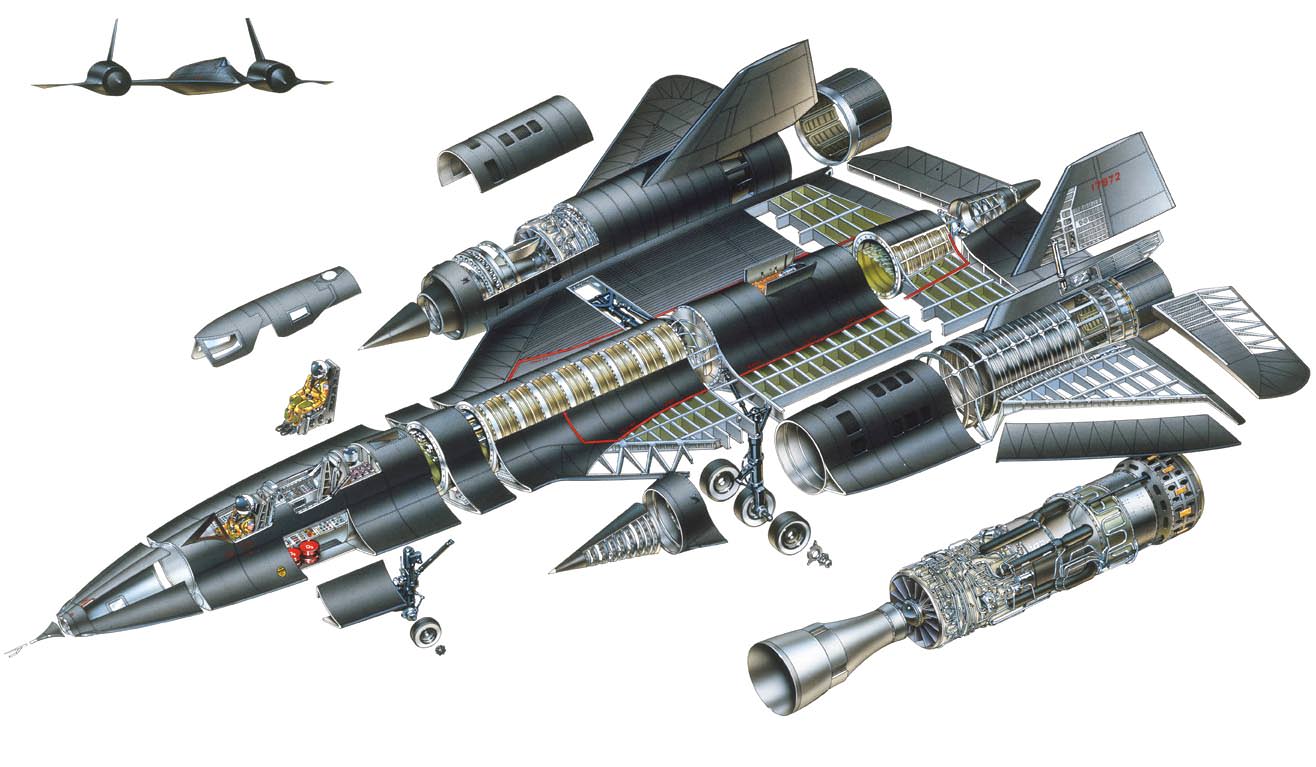

Since the 1950s, titanium alloys have been developed in the aerospace industry. In this application, the mechanical properties, low density and corrosion resistance of titanium alloys are utilised. Airframe materials require high tensile strength, fatigue resistance and fracture toughness. Their high-temperature tensile strength, creep resistance and stability at elevated temperatures enable use in jet engines.

Titanium alloys serve as structural materials for modern aircraft and engines. They reduce the weight of the aircraft and increase structural efficiency. The payload of a spacecraft is relatively low compared to that of an aircraft, thereby making weight reduction of its structure more critical. Titanium alloys were used during the early Apollo programme and in the Mercury project. Fuel tanks and satellite modules are typical applications for titanium alloys. Titanium alloys are preferable to high-strength steels for use with fuel because they have lower weight, high strength and long-term chemical stability. For example, the alloy Ti-3Al-2,5V was developed for low-temperature applications. It demonstrates toughness and ductility under cryogenic conditions in space.

See also: How is titanium employed in aerospace?

Conclusion

We thank you for reading this article and hope that it has provided you with a better understanding of the titanium used in the aerospace industry. If you wish to learn more about titanium products, we recommend that you visit Stanford Advanced Materials (SAM) for further information.

Stanford Advanced Materials (SAM) is a global supplier of titanium products and has more than two decades of experience in the production and distribution of titanium materials. We supply products that meet the research and production requirements of our customers. We are confident that SAM will be your preferred supplier of titanium and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento