What Are The Differences Between Traditional Alloys And High-Entropy Alloys?

Introduction

Conventional alloys and high entropy alloys (HEAs) are two types of materials employed in various technical applications. Both consist of metallic elements; however, there are essential differences between these alloys. This article examines the differences between traditional alloys and HEAs in terms of composition, microstructures, properties, applications and production methods.

[1]

[1]

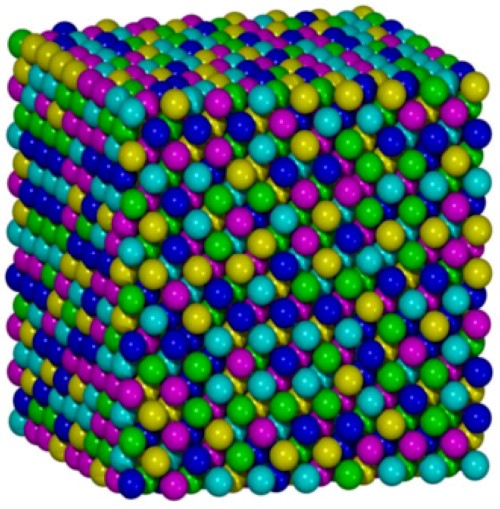

Figure 1. Automatic model of HEAs

Introduction to Conventional and High Entropy Alloys

Traditional alloys combine one primary metallic element with additional metal or non-metal elements. In these alloys some properties of the original base metal remain, while other characteristics, such as increased strength or improved ductility, are altered.

A variety of alloying elements can be added to base metals. Chromium is frequently incorporated to enhance corrosion resistance; tungsten is used to improve wear resistance at elevated temperatures; and carbon is commonly added to steel and cast iron to increase strength.

High entropy alloys are defined as alloys that contain five or more principal elements, each present at an atomic percentage between 5% and 35%. The inclusion of multiple elements produces a complex structure and a high entropy effect, which gives rise to the distinct physical and mechanical properties of HEAs when compared with conventional alloys.

Stanford Advanced Materials (SAM) has extensive experience in the manufacture and supply of high entropy alloy products. On our website you will find a wide selection of high entropy alloy powders, spherical powders and ingots. Please contact us if you are interested.

Conventional Alloys vs. High Entropy Alloys

-Composition

Conventional alloys and high entropy alloys differ in their elemental composition. Conventional alloys typically consist of two or three metallic elements in varying proportions. HEAs, by contrast, contain at least five elements in equal or nearly equal atomic percentages. In conventional alloys the base metal constitutes the majority, whereas in high entropy alloys the elements occur in equal or near-equal proportions.

--Microstructure

The different compositions lead to different microstructures. Conventional alloys usually exhibit a well-defined microstructure, for example a eutectic or dendritic pattern, while HEAs display a disordered, homogeneous microstructure. The disordered nature of HEAs results in a random distribution of atoms, thereby reducing the incidence of phase transformations even at elevated temperatures.

-Properties

Conventional alloys exhibit a range of properties depending on their composition and microstructure. Some conventional alloys are hard yet brittle, whereas others are ductile but exhibit lower strength.

In contrast, HEAs provide a combination of properties including high strength, ductility and thermal stability because of their disordered microstructure. For example, VNbMoTaW is an alloy that maintains a yield strength exceeding 600 MPa and 87 ksi at 1 400 °C, thereby offering performance that may exceed that of some conventional superalloys.

-Applications

Conventional alloys are widely used in various sectors, including the automotive industry, aerospace and construction.

HEAs are a relatively new class of materials whose practical applications are still under investigation. They have been employed in high-temperature thermoelectric applications, wear-resistant coatings and structural components. For instance, HEAs are used in the automotive sector to manufacture engine components, drive system parts and other structural equipment. Their mechanical performance at elevated temperatures, along with radiation and corrosion resistance, renders these alloys promising for nuclear-related applications.

-Manufacturing

The manufacturing process for conventional alloys is relatively straightforward, while several methods exist for the production of high entropy alloys.

Conventional alloys are typically produced using established methods such as casting, extrusion and forging. Generally the process comprises melting, mixing, solidification and subsequent cooling.

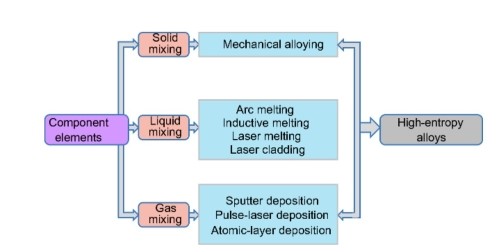

The production of HEAs requires specialised techniques because of their complex composition and microstructure (see Figure 2). The majority of HEAs are produced by arc melting and induction melting. In solid-state processing, mechanical alloying is employed. Gas-phase processing methods include sputtering and molecular beam epitaxy (MBE).

[2]

[2]

Figure 2. Production of HEA

Conclusion

In summary, conventional alloys and high entropy alloys differ in terms of composition, microstructure, properties, applications and manufacturing methods. While conventional alloys exhibit a defined microstructure and specific properties, HEAs provide a distinct combination of attributes due to their disordered, homogeneous microstructure. HEAs remain a promising class of materials for a range of applications and are under active investigation to ascertain their full potential. Stanford Advanced Materials (SAM) is a reliable supplier of high entropy alloys. For further information, please visit our homepage.

References:

[1] High entropy alloy. (05/06/2023). In Wikipedia. https://en.wikipedia.org/wiki/High-entropy_alloy#See_also

[2] Zhang, Wei & Zhang, Yong. (2018). Scientific and technical investigations in high entropy alloys. Science China Earth Science. 2-22.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento