GGG Vs. SGGG Crystal Substrates: Which Is The Superior Choice For Your Tech Needs?

1 Introduction

Gadolinium-Gallium-Garnet (GGG) and Samarium-Gadolinium-Gallium-Garnet (SGGG) are crystals with a garnet structure. They exhibit quantifiable optical properties, including non‑linear optical behaviour and magneto‑optical effects, as well as measurable magnetic and thermal characteristics. Consequently, they are employed in optoelectronics, sensor technology and magnetism. In terms of material properties, SGGG shows increased optical, magnetic, thermal and electrical performance as a result of Sm3+ incorporation compared with GGG, although GGG remains the standard in view of its stability and developmental maturity.

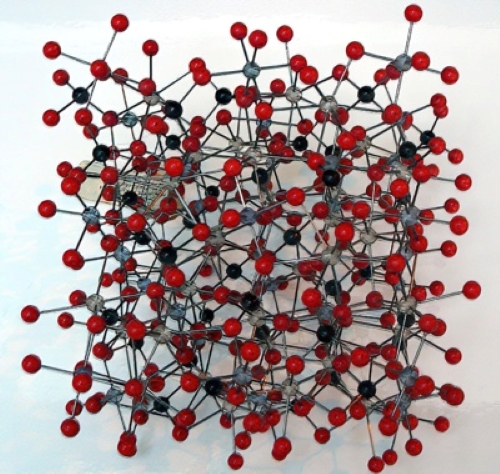

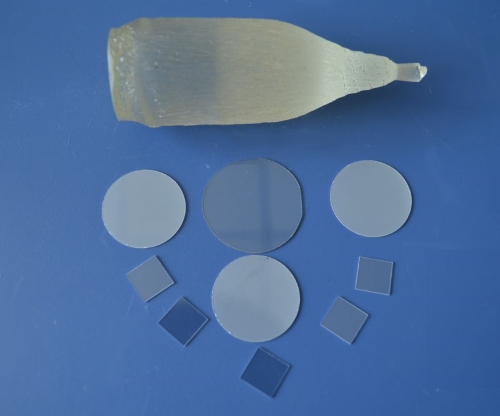

2 The Crystal Structure of GGG and SGGG

The crystals of Gadolinium-Gallium-Garnet (GGG) belong to the cubic crystal system, a type of isometric system. The lattice constant is 12.383 Å and the crystallographic unit cell comprises 8 chemical formula units. As a derivative of the garnet crystal family, its structure conforms to that of a garnet, with Gd3+ and Ga3+ occupying the positively charged ion positions within an orthooctahedral or tetrahedral framework of [GaO4]4-. In addition, although garnet typically crystallises in an orthorhombic dodecahedral form, deltoidal icositetrahedra may also be present.

Samarium-Gadolinium-Gallium-Garnet (SGGG) is produced by substituting a portion of Ga3+ in GGG with Sm3+. Its appearance and crystal structure are essentially similar to those of GGG. The ionic radius of Sm3+ is larger than that of Ga3+; consequently, the substitution results in a slight distortion of the crystal structure, thereby causing minor differences in the material properties.

3 Optical Properties of GGG and SGGG and Associated Applications

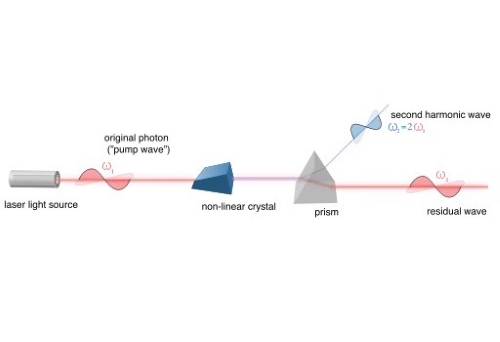

3.1 Non‑linear Optical Properties

GGG and SGGG belong to the cubic crystal system. Their structures are non‑centrosymmetric; as a result, the inversion centre is absent. This results in measurable second‑order non‑linear effects such as Second Harmonic Generation (SHG) and Optical Parametric Oscillation (OPO). Consequently, both crystals exhibit non‑linear optical behaviour and are applied in laser systems, optical communication devices and sensor technology.

3.1.1 Applications Related to the Non‑linear Optical Properties of GGG

Laser Technology: GGG is used to produce components for Second Harmonic Generation (SHG) and optical parametric oscillators (OPO). These components are applied in frequency doubling, frequency mixing and other processes in laser processing, spectral analysis and biomedical imaging.

LIDAR Systems: GGG is employed in the fabrication of non‑linear optical elements for LIDAR systems. These elements modulate, combine and detect laser beams. LIDAR technology is applied in remote sensing, geological surveying, aerospace and other fields.

Optical Communication and Sensor Technology: GGG is utilised in devices such as optical modulators and switches. These devices regulate the transmission and processing of optical signals, thereby achieving efficient and low‑loss performance, and are also used in optical sensors that measure intensity, frequency and phase. Such sensors are applied in environmental monitoring, medical diagnostics and industrial process control.

3.1.2 Enhanced Non‑linear Optical Properties of SGGG

SGGG crystals are doped with Sm3+ to substitute part of the Ga3+ in GGG, resulting in a slight alteration of the crystal structure and measurable changes in optical properties. The introduction of Sm3+ produces an additional non‑linear polarisation mechanism. Consequently, SGGG exhibits higher non‑linear optical coefficients and increased conversion efficiency in certain applications. However, the changes also lead to a slight reduction in the stability of its optical performance. When high stability and consistency are required, GGG remains the preferred material.

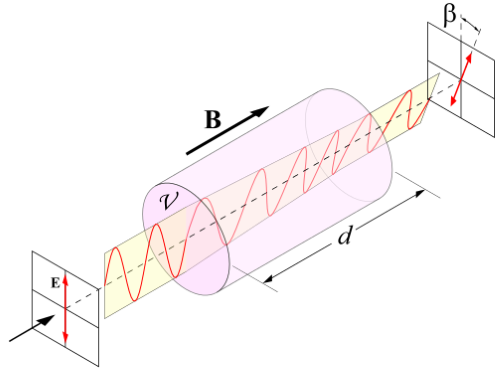

3.2 Magneto‑optical Properties

GGG and SGGG display magneto‑optical characteristics. The magneto‑optical effect refers to changes in a material’s optical properties under an applied magnetic field. This may be observed as a modification of light polarisation, refractive index or absorption. The effect in GGG arises from the interaction between its crystal structure and internal ions, in combination with the applied magnetic field. Under the influence of a magnetic field, the spins and orbital motions of the ions (typically transition metal ions) interact with photons, thereby causing a rotation in the polarisation direction of the light. This effect is known as the Faraday Effect.

3.2.1 Applications Related to the Magneto‑optical Effect

Magneto‑optical Storage: The magneto‑optical effect in GGG is employed in storage devices that permit data to be written, read and erased. These systems offer high data density, fast operation and stable long‑term performance.

Optical Devices for Communication and Sensor Technology: GGG and SGGG are used in the production of optical modulators and switches. These devices regulate optical signals in applications such as magnetic field measurement and mapping when implemented within optical fibres. Magneto‑optical fibre sensors exhibit high sensitivity, rapid response and considerable resistance to interference and are used in magnetic field measurements and mapping.

Optical Isolators: The magneto‑optical effect is also exploited in the manufacture of optical isolators, which prevent reverse propagation and cross‑talk of optical signals. These isolators are essential in optical communication systems where system performance must be maintained.

3.2.2 Enhanced Effects in SGGG

Compared with GGG, SGGG exhibits a more pronounced magneto‑optical response due to Sm3+ doping and the presence of unpaired electrons from transition metal ions. Nonetheless, both crystals offer specific advantages in terms of stability and application.

3.3 Terahertz Response

The term Terahertz response denotes a material’s behaviour within the terahertz band (typically defined as electromagnetic waves with frequencies from approximately 0.1 THz to 10 THz). This band exhibits particular characteristics, including significant penetration, a non‑ionising effect and distinct absorption properties in biological tissues and various materials. The magneto‑optical response of GGG and SGGG in the frequency range of 30 GHz to 1 THz, together with the material’s response tensor, was investigated by Mohsen Sabbaghi et al. In this spectral region, the materials display low dispersion and minimal optical signal attenuation. Under low‑temperature conditions, measurable terahertz Faraday rotation was observed in the (S)GGG samples, a behaviour that is likely related to the increased paramagnetic spin state of Gd3+ ions.

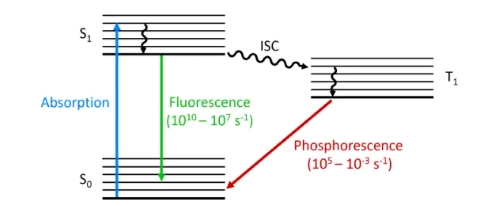

3.4 Photoluminescence

A comparative analysis of the EPR, optical absorption (OA) and luminescence spectra of GGG single crystals was conducted by N. Mironova‑Ulmane et al. In crystals exposed to maximum neutron flux, the EPR spectra revealed several paramagnetic defects. In unirradiated GGG, photoluminescence is attributed to random impurities. However, neutron irradiation of GGG produces a broad asymmetric luminescence spectrum with a defined peak in the range of 725 to 733 nm. The intensity of this peak increases in proportion to the neutron fluence. Consequently, this spectral band is associated with radiation‑induced defects in the material.

Photoluminescence technology is applied in biological and chemical analysis (fluorescence marking, fluorescence spectroscopy etc.), optical sensor technology and in various lighting devices such as fluorescent lamps and LED systems. Continued research into the properties of GGG suggests that its fields of application may be extended further in future.

4 Magnetic Properties of GGG and SGGG and Corresponding Applications

GGG and SGGG exhibit magneto‑optical characteristics because the magnetisation of the material under an applied magnetic field leads to measurable changes in optical properties. The magnetisation properties are fundamental to their broad range of applications. Both materials demonstrate ferromagnetism primarily due to the magnetic moment of Gd3+. This is expressed in both the magnetisation phenomenon and the magneto‑optical effect under an applied magnetic field.

Since the outer electrons of Gd3+ are predominantly 4f electrons, they contain several unpaired spins. This results in a high spin momentum for gadolinium atoms, which imparts a large intrinsic magnetic moment at room temperature. The cubic crystal structure ensures that the spin directions of Gd3+ ions are ordered, thereby forming magnetic domains. Consequently, this ordered arrangement contributes to the observable macroscopic magnetic properties.

In practical terms, ferromagnetic garnet films can be grown on GGG substrates for use in magneto‑optical devices and magnetic bubble memory. Additionally, the epitaxial growth of III‑V compound semiconductors on GGG substrates is applicable for optical communication systems, for example in integrated magneto‑optical isolators, laser diodes, circuits incorporating transmitters, detectors, isolators, circulators, non‑overlapping interconnects and modulators, in addition to magnetic recording systems with integrated magnetic read heads and magnetometry.

5 Thermal Properties of GGG and SGGG and Related Applications

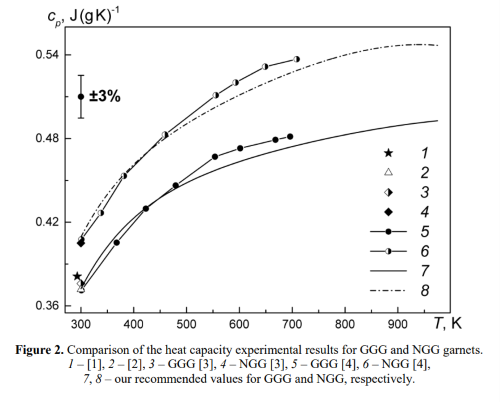

Synthetic crystals with a garnet structure are applied not only in quantum electronics but also across various scientific and technical fields. The study of their thermophysical properties is essential for facilitating precise technical computations, which are necessary for the design and optimisation of devices. Without detailed data on these properties, it is difficult to accurately assess device performance and reliability. D. A. Samoshkin and S. V. Stankus et al. provided new experimental data on the heat capacity of NGG and GGG over the solid‑state temperature range of 300–975 K. The results were compared with existing literature data. For the first time, measurements were recorded for the temperature range of 700–975 K. Under these conditions, the heat capacity coefficient of GGG increases gradually with temperature, with the rate of increase slowing to form a more steady trend.

6 Production of GGG and SGGG

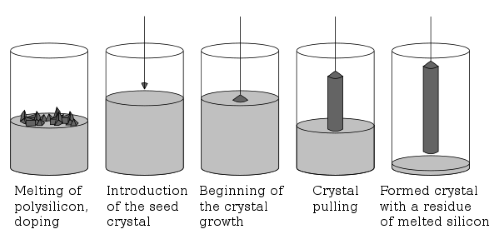

During the production of GGG and SGGG crystals by the Czochralski Method, precise control of temperature and lifting rate is essential.

Temperature Control: In the Czochralski process, accurate temperature management within the melt is critical. A temperature gradient is maintained such that the melt is at its melting point at the solid‑liquid interface, while a degree of undercooling is generated around the seed crystal. This undercooling prevents additional nucleation and facilitates the orderly arrangement of atoms or molecules into a single‑crystal structure. Continuous heat supply by the heater is necessary to maintain the melt at a temperature well above ambient conditions.

Lifting Rate: The speed at which the crystal is raised significantly influences its growth rate and quality. An optimised rotational speed ensures effective mixing within the melt and minimises radial temperature gradients, thereby preventing excessive undercooling. Generally, a lifting speed of between 6 and 15 mm per hour is employed to achieve the desired growth characteristics.

High‑quality, seed‑free GSGG crystals exhibiting less than 5 defects/cm² from iridium inclusions and dislocations were produced by D. F. O'Kane et al. using a computer‑controlled Czochralski crystal growth monitoring system. A pure nitrogen atmosphere within the crystal growth apparatus successfully reduced iridium inclusions. During crystal growth, a high rotational speed together with a slow pull rate prevented additional nucleation; however, at high rotational speeds, streaks were observed. Dislocations were minimised by maintaining precise control of the crystal diameter throughout growth. An etching procedure was devised to visualise dislocations. The lattice parameters of GGG remained unchanged during the 26‑hour growth period. An excess of Ga₂O₃ in the melt caused only a slight decrease in the lattice parameter, whereas an excess of Gd₂O₃ significantly increased it.

7 Conclusion

Gadolinium-Gallium-Garnet (GGG) and Samarium-Gadolinium-Gallium-Garnet (SGGG) are crystalline materials recognised for their garnet structure and quantifiable optical, magnetic and thermal properties. These measured characteristics, including non‑linear optical and magneto‑optical effects, render them suitable for applications in optoelectronics, sensor technology and magnetism. Although SGGG exhibits improved optical, magnetic, thermal and electrical properties due to Sm3+ incorporation, GGG remains the standard material owing to its established stability and mature developmental record.

Further Reading:

Innovationen in der Optik: Die Rolle von GGG-, SGGG- und NGG-Garnet-Boules

Reference

[1] Mironova‑Ulmane N, Popov A, Antuzevics A, et al. EPR and optical spectroscopy of neutron‑irradiated Gd₃Ga₅O₁₂ single crystals [J]. Nuclear Inst. and Methods in Physics Research, B, 2020,480.

[2] Mohsen S, W. G H, Michael W, et al. Terahertz response of Gadolinium‑Gallium‑Garnet (GGG) and Gadolinium‑Scandium‑Gallat (SGGG) [J]. Journal of Applied Physics, 2020, 127(2).

[3] Samoshkin A D, A D S, V S S. Heat capacity of Neodymium‑ and Gadolinium‑Gallium‑Garnets [J]. Journal of Physics: Conference Series, 2020,1677(1).

[4] O'Kane F D, Sadagopan V, Giess A E, et al. Crystal Growth and Characterisation of Gadolinium Gallium Garnet [J]. Journal of The Electrochemical Society, 2019,120(9).

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento