Multi-Leaf Collimators: A Comprehensive Guide With Cases

What is a Multi‐Leaf Collimator?

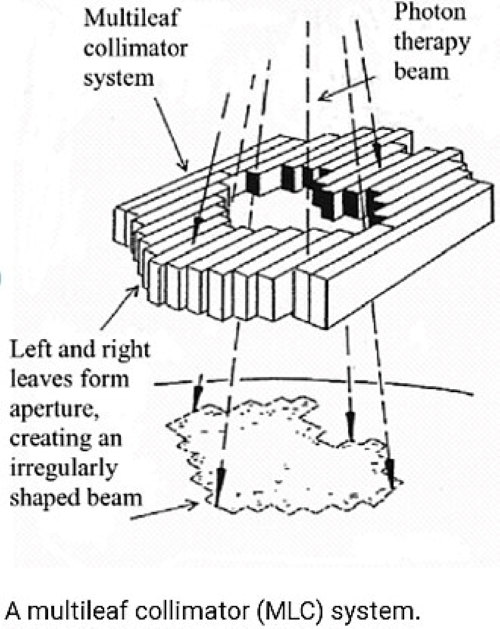

A Multi‐Leaf Collimator (MLC) is an advanced device integrated into radiotherapy machines to shape and direct radiation beams with precision. MLCs consist of numerous independently movable tungsten alloy leaves or shields and replace older methods such as patient‐specific lead blocks for targeted irradiation.

The primary function of an MLC is to conform the radiation beams to the shape of the tumour and thereby reduce exposure to adjacent healthy tissue. Its high‐density design and automated operation allow treatment that is both safer and more effective.

How Multi‐Leaf Collimators Operate

[1]

[1]

An MLC consists of 20 to 80 tungsten alloy leaves that are independently movable and controlled by computer software. These leaves can be extended or retracted to shape the radiation beam in accordance with the tumour geometry and produce a customised radiation field.

This automated process enables the following:

- Dynamic shaping: Adjustments in real time during treatment.

- Intensity modulation: Varied radiation intensities across the field, thereby allowing a more effective therapy.

- Protection of healthy tissue: Shielding of organs or tissues adjacent to the tumour.

Applications in Radiotherapy

MLCs are commonly employed in the treatment of cancers, for example:

- Liver cancer: Protection of vital organs such as the liver during treatment.

- Lung cancer: Shaping of the beams to avoid sensitive tissue.

- Breast cancer: Shielding of the heart and lungs from radiation exposure.

Their ability to generate customised radiation fields renders them indispensable for advanced techniques such as IMRT and volumetrically modulated arc therapy (VMAT), where accuracy and control are essential.

Transition from Cerrobend to Multi‐Leaf Collimators

Traditionally, lead‐based alloys such as Cerrobend were used to manufacture custom radiation blocks for beam shaping. These Cerrobend blocks were produced manually for each patient, which required labour‐intensive work and generated hazardous waste.

The adoption of MLCs has largely obviated the need for Cerrobend blocks:

- Technological advancements: MLCs allow dynamic beam shaping without manual intervention.

- Environmental considerations: The manufacture and disposal of Cerrobend involve toxic materials.

- Operational efficiency: MLCs reduce preparation time, thereby enabling faster and more precise treatment.

This change improves patient safety, reduces environmental impact and increases operational efficiency.

Case Study on Multi‐Leaf Collimators (MLCs)

-Overview

The replacement of Cerrobend blocks with MLCs made of tungsten alloy improves the precision in radiotherapy while reducing impacts on both the environment and health.

--Background

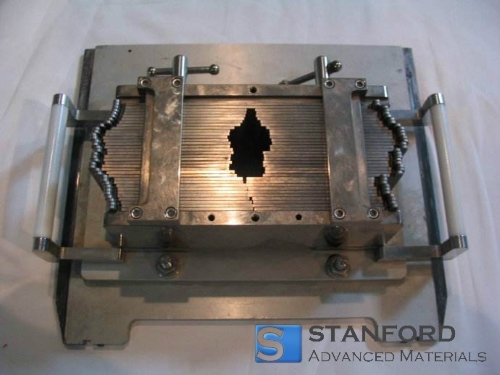

In the past, Cerrobend, a lead‐based alloy, was frequently used in radiotherapy for the manufacture of custom blocks to shape radiation beams. However, the production of Cerrobend generates hazardous waste due to its toxicity, thereby posing an environmental issue. A healthcare professional requested Stanford Advanced Materials (SAM) for permission to use an image of multi‐leaf collimators (MLCs) to illustrate this transition in a presentation on waste management in hospitals. Given technological advancements, tungsten alloy MLCs have provided a practical alternative.

-Solution

SAM supported the educational initiative by supplying the requested image and technical insights into tungsten alloy MLCs. Tungsten alloys with a density between 17.0 g/cm³ and 18.6 g/cm³ offer excellent radiation absorption and ensure patient safety during treatment. In contrast to Cerrobend, tungsten is non‐toxic and free from harmful substances, thereby representing an environmentally sound choice. Tungsten MLCs are equipped with 20 to 80 computer‐controlled, movable shields or leaves that allow for precise shaping of the radiation fields. Consequently, the radiation exposure of healthy tissue is reduced, making them particularly suitable for the treatment of liver, lung and breast cancer.

--Result

The presentation clearly demonstrated the environmental and operational benefits of tungsten alloy MLCs compared to Cerrobend blocks. Healthcare professionals obtained insights into the benefits of MLCs, including:

- Enhanced safety: Shielding patients from unnecessary radiation exposure.

- Environmental friendliness: Elimination of the hazardous waste associated with Cerrobend.

- Accurate treatment: Generation of customised radiation fields with computer‐controlled shields.

This initiative encouraged hospitals to adopt tungsten alloy MLCs, thereby advancing cancer treatment practices with reduced risk and lower environmental impact while also illustrating the role of SAM in facilitating the adoption of new technologies.

Materials for Multi‐Leaf Collimators

The choice of materials is critical for the performance and safety of MLCs. Tungsten alloys are considered the standard given their specific properties:

- High density: With a density between 17.0 g/cm³ and 18.6 g/cm³, the tungsten alloy effectively absorbs radiation, minimises leakage and ensures patient safety.

- Non‐toxic: In contrast to lead‐based materials such as Cerrobend, tungsten is non‐toxic and environmentally friendly, thereby offering increased safety for both patients and medical staff.

- Durability: Tungsten alloys are resistant to wear and corrosion, thereby ensuring durability and consistent performance in radiotherapy equipment.

Although other materials such as depleted uranium and tantalum have been investigated, tungsten alloys remain the preferred choice due to their balanced performance, safety and environmental impact.

Conclusion

Multi‐Leaf Collimators modify cancer treatment by enabling precise, efficient and environmentally compatible radiotherapy. The transition from conventional Cerrobend blocks to tungsten alloy MLCs constitutes progress in medical technology that improves patient outcomes and reduces environmental impact. Further materials and related case studies can be found at Stanford Advanced Materials (SAM).

Reference:

[1] Multileaf Collimator. (16/05/2024). In Wikipedia. https://en.wikipedia.org/wiki/Multileaf_collimator

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento