Sodium Hyaluronate Products Of Different Technical Specifications: Molecular Weight And Viscosity

Introduction

Sodium hyaluronate (SH), the salt form of hyaluronic acid, is a naturally occurring polysaccharide. It is utilised in both cosmetic and medical industries because it may enhance skin moisture, skin texture and overall appearance. SH is available in several technical specifications, including different molecular weights and viscosities; these parameters affect its performance in various applications. This article examines the different types of SH products and their specific applications, thereby assisting research and industrial selection.

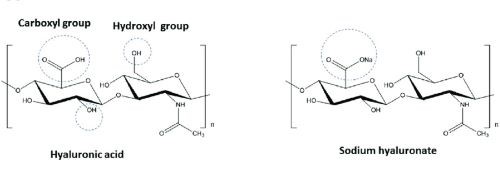

Figure 1. Chemical structure of HA and SH

Sodium Hyaluronate: Molecular Weight

The molecular weight of SH is an essential parameter that determines its physical and biological properties. Generally, a higher molecular weight results in increased viscosity and elasticity. Consequently, SH with a higher molecular weight is preferred for cosmetic applications, while SH with a lower molecular weight is used in medical applications, given that it is absorbed more efficiently.

- Low-molecular-weight SH (LMW-SH): LMW-SH has a molecular weight of less than 1 000 kDa and is commonly used in medical treatments such as joint injections for the treatment of osteoarthritis. It exhibits high bioavailability and may reduce inflammation and improve joint function.

- Medium-molecular-weight SH (MMW-SH): MMW-SH has a molecular weight between 1 000 and 1 500 kDa and is typically applied in cosmetic procedures, for example as a dermal filler and a skin moisturiser. It offers a moderate viscosity and elasticity that can be effective in reducing fine lines.

- High-molecular-weight SH (HMW-SH): HMW-SH has a molecular weight of more than 1 500 kDa and is equally used in cosmetic applications. Its high viscosity and elasticity are beneficial for sustaining skin volume and moisturisation over longer periods.

Further reading: High vs. Low Molecular Weight Hyaluronic Acid

Sodium Hyaluronate: Viscosity

The viscosity of SH is another critical parameter that influences its suitability for distinct applications. Highly viscous SH is employed in cosmetic products to provide a thick, gel-like consistency that fills wrinkles and adds volume. In contrast, low-viscosity SH is used in medical applications because it is easier to inject.

- Low-viscosity SH: Low-viscosity SH has a viscosity of less than 50 000 mPa·s and is typically formulated for joint injections and other medical devices. It features high bioavailability and can be rapidly absorbed, thereby reducing inflammation and improving joint performance.

- Medium-viscosity SH: Medium-viscosity SH has a viscosity ranging from 50 000 to 1 000 000 mPa·s and is used in the production of dermal fillers, moisturising creams and other cosmetic products. It provides a moderate consistency that fills wrinkles and adds volume to the skin.

- High-viscosity SH: High-viscosity SH has a viscosity greater than 1 000 000 mPa·s and is applied in cosmetic formulations. It offers a thick, gel-like consistency that may maintain skin volume and moisturisation for an extended period.

Further reading: Viscosity, Molecular Weight and Rheological Properties of HA

Conclusion

In summary, sodium hyaluronate products are available with various technical specifications, including different molecular weights and viscosities. The precise selection of an SH product based on its technical parameters is vital for achieving the desired performance while ensuring safety and efficacy. By selecting the appropriate SH formulation for a given application, healthcare providers and industry users may benefit from the functional properties of this polysaccharide.

Stanford Advanced Materials (SAM) is a reliable supplier of sodium hyaluronate in various specifications. We provide sodium hyaluronates with high, medium and low molecular weights. Custom formulations are available. Please visit our website for further information.

Reference:

[1] Khaleghi, Maryam; Ahmadi, Ebrahim; Shahraki, Mahvash; Aliakbari, Farhang; Morshedi, Dina. (2020). Temperature-dependent formulation of a hyaluronic acid-polydimethylsiloxane hydrogel for biomedical applications. Heliyon, 6, e03494. doi:10.1016/j.heliyon.2020.e03494.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento