Specific Gravity: Liquids, Gases, And Solids

Below is a detailed compendium of measured specific gravities for various substances. The data are presented in tables and are provided for academic and industrial reference.

Specific Gravities of Liquids

|

Liquid Substances |

(°C) |

(SG) |

|

1-Propanol |

20 |

0.803 |

|

2-Propanol |

20 |

0.786 |

Specific Gravities of Gases

|

Gases |

|

|

Acetylene (Ethyne) |

0.899 |

|

Air |

1.000 |

|

Alcohol Vapour |

1.601 |

Specific Gravities of Solids

|

Solids and Metals |

Specific Gravity |

|

ABS, extrusion type |

1.05 |

|

Acrylic Glass |

1.19 |

|

3.4 |

|

|

Antimony |

6.69 |

|

Asphalt |

1.10 |

|

Cork |

0.25 |

|

Baryte |

4.50 |

|

Baryte |

3.62 |

|

Beryllium |

1.848 |

|

Bismuth |

9.79 |

|

Boron |

2.32 |

|

Cast Brass (rolled and cast) |

8.40 8.70 |

|

Red Brick |

1.75 |

|

Chamotte Brick |

2.40 |

Specific Gravity: FAQs

1. What is specific gravity?

Specific gravity is the ratio of the density of a substance to the density of a reference material (typically water) at specified conditions of temperature and pressure. This dimensionless quantity indicates the relative density of materials.

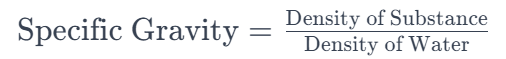

2. How is specific gravity calculated?

Specific gravity is determined by dividing the density of the substance by the density of the reference material. The formula is provided below:

3. Why is specific gravity important?

Specific gravity provides a quantitative comparison of a material’s density against water. It assists in predicting whether a substance will float or sink when immersed and supports material selection in diverse scientific and engineering applications.

4. What does the value of specific gravity indicate?

l A value less than 1 indicates a density lower than water, implying buoyancy.

l A value greater than 1 indicates a density higher than water, leading to sinking in water.

5. Can specific gravity change?

Yes. Specific gravity may vary with alterations in temperature, pressure and physical state. Materials typically expand or contract with temperature, impacting their density and, consequently, their specific gravity.

6. How is specific gravity used across industries?

l In brewing, specific gravity measurements quantify sugar content before and after fermentation.

l In mining and metallurgy, it aids in assessing ore quality and mineral concentration.

l In construction, specific gravity helps evaluate the quality of concrete and aggregates.

7. How is specific gravity measured?

l Hydrometers measure the density of liquids to determine specific gravity.

l Pycnometers determine the volume of solids and liquids to calculate density and specific gravity.

l Archimedes’ principle is used for irregularly shaped solids to measure their displacement and density.

8. Are there limitations in using specific gravity?

Specific gravity is a useful quantitative parameter. However, it does not provide detailed compositional information and requires standard conditions for accurate comparison.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento