A Comprehensive Guide To Powder Bed Fusion Technique

The Powder Bed Fusion process (PBF) is an additive manufacturing technique that offers measurable advantages over conventional methods. This guide examines various aspects of PBF, its advantages, applications and its impact on sectors such as aerospace, medical technology and automotive engineering.

Understanding Powder Bed Fusion

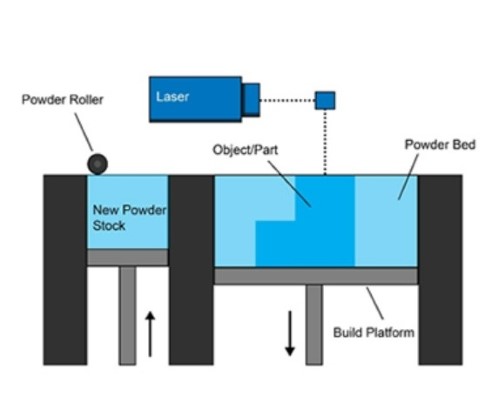

Powder Bed Fusion (PBF) is an additive manufacturing technology that uses powdered materials to build solid objects. A digital model directs the production steps. A thin layer of powder is spread over a build platform. A heat source, for example a laser or an electron beam, is applied to fuse the powder in line with the digital model. After each layer is processed, an additional layer is spread. This procedure is repeated until the entire object is produced.

Figure 1. Powder Bed Fusion Process

Types of Powder Bed Fusion

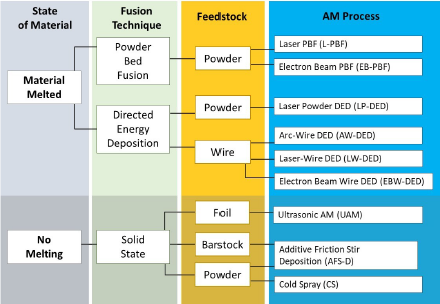

PBF is divided into two categories: Laser Powder Bed Fusion (L-PBF) and Electron Beam Powder Bed Fusion (EB-PBF). L-PBF processes use a laser as the energy source to fuse powdered materials layer by layer. In EB-PBF, an electron beam is employed to fuse mainly metal powders. Other methodologies are also applied in PBF. Additional information is provided in the figure below.

Figure 2. AM Process Options

Advantages of Powder Bed Fusion

PBF offers several advantages compared to conventional manufacturing methods.

1. Complex geometries: PBF can produce parts with internal channels, lattice structures and designs optimised for weight reduction. Such intricate features are difficult to achieve by conventional techniques.

2. Design flexibility: This process permits extensive design customisation. Multiple components can be integrated into one part, thereby reducing assembly steps.

3. Material versatility: PBF can process metals, polymers and ceramics. This broad material range enables production of parts with varied mechanical, thermal and chemical properties.

4. Reduced material waste: Only the required amount of powder is utilised. This results in lower waste when compared with traditional manufacturing methods.

5. Customisation and personalisation: The technique allows production of bespoke components. Detailed fabrication typical in medical and dental applications can be achieved accordingly.

Applications of Powder Bed Fusion

PBF is applied in several industries due to its specific advantages.

1. Aerospace: In the aerospace sector, PBF is used to manufacture lightweight and complex parts. For instance, a fuel nozzle produced by PBF is used in the GE9X engine of the Boeing 777. Components such as turbine blades, structural supports and heat exchangers are also produced, thereby contributing to weight reduction and improved fuel efficiency.

2. Medical and Dental: In medical and dental technology, PBF is employed to produce customised implants, prostheses, surgical guides and devices. The ability to manufacture intricate geometries ensures better fit and functionality for patients.

3. Automotive: PBF is used in the automotive industry to create functional prototypes, tooling, fixtures and brackets. Lightweight engine parts, brackets and intake manifolds produced by PBF can improve fuel efficiency and overall vehicle performance.

4. Other uses

- Tool manufacture and production aids: PBF methods are used to create injection moulding inserts, casting models and fixtures.

- Jewellery and art: PBF is employed for fabricating detailed sculptures, decorative objects and art installations.

- Energy: Components for power generation and distribution are produced using PBF.

Further reading: New 3D Printing Material – Refractory Metal

Conclusion

In summary, Powder Bed Fusion is a significant additive manufacturing technique used to produce high-performance components. Its capacity for precise design, varied material use, reduced waste and customisation meets the requirements of aerospace, medical, automotive and other sectors where tailored production is necessary.

Stanford Advanced Materials (SAM) offers high-quality 3D printing materials at competitive prices. Custom products using the PBF technique are available. Please submit an enquiry if you are interested.

Reference:

[1] Forschungsgruppe Additive Fertigung. Pulverbettfusion. Universität Loughborough. https://www.lboro.ac.uk/research/amrg/about/the7categoriesofadditivemanufacturing/powderbedfusion/

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento