Additive Manufacturing: What You Need To Know

Description

In additive manufacturing, also known as 3D printing, components are constructed layer by layer. This method achieves precision, efficiency and permits the use of various materials.

Content

Additive manufacturing, also referred to as 3D printing, has affected sectors including aerospace, automotive, and healthcare. It enables the production of intricate parts directly from digital models by depositing successive material layers. Unlike conventional methods that remove material from a larger block, this process produces complex designs with reduced material waste and decreased production time.

Key processes in additive manufacturing include the powder bed fusion, direct energy deposition, material extrusion, binder jetting and stereolithography. The powder bed fusion method is applied particularly in instances where high-performance metal components are required. It relies on spherical metal powders. The specific attributes of these powders, such as particle size distribution, flowability and purity, affect the quality and performance of the final product.

Spherical Metal Powders

Spherical Metal Powders are employed in additive manufacturing processes such as selective laser melting (SLM) and electron beam melting (EBM). Their spherical shape allows for smooth flow and uniform layer deposition, which is important for achieving consistent parts. These powders are mainly produced by gas atomisation, plasma atomisation or via the rotating electrode process. Each production method yields powders with specific properties that are selected for particular applications.

Titanium alloys, aluminium alloys, stainless steels, cobalt-chrome alloys and nickel-based superalloys are commonly used materials in additive manufacturing. Titanium and cobalt-chrome alloys are used in medical implants because they offer biocompatibility and high strength, while nickel-based superalloys are chosen for aerospace components due to their high heat resistance.

Material Comparison Table for Additive Manufacturing

The selection of an appropriate material is essential for successful additive manufacturing. The table below details the key properties and typical applications of the metals commonly used in this process:

|

Material Type |

Strength |

Corrosion Resistance |

Weight |

Applications |

|

Titanium Alloys |

High |

Excellent |

Light |

Aerospace, medical implants |

|

Aluminium Alloys |

Moderate |

Good |

Very light |

Automotive, aerospace |

|

Stainless Steels |

High |

Excellent |

Heavy |

Tools, automotive, industrial |

|

Cobalt-Chrome Alloys |

Very high |

Excellent |

Heavy |

Medical, dental implants |

|

Nickel-based Superalloys |

Very high |

Good |

Heavy |

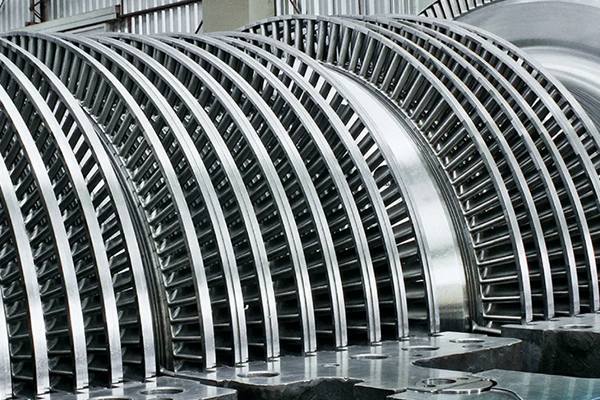

Aerospace, gas turbines |

This table assists engineers and designers in selecting appropriate materials by considering parameters such as strength, corrosion resistance, weight and industry requirements. Further details can be found at Stanford Advanced Materials (SAM).

Additive manufacturing offers measurable benefits including rapid prototyping, customised small-batch production and shortened time-to-market. The industry increasingly uses these technologies to produce parts that are impractical or uneconomical to manufacture by conventional methods.

Frequently Asked Questions

Frequently Asked Questions

Which sectors benefit most from additive manufacturing?

The aerospace, automotive, medical, dental and defence sectors benefit substantially from additive manufacturing because this process facilitates the production of intricate and custom parts.

Why are spherical metal powders used instead of other forms?

Spherical metal powders offer improved flowability and packing density, thereby ensuring uniform layer deposition and appropriate mechanical properties in the final product.

Which challenges commonly occur in additive manufacturing?

Common challenges include selecting the correct material, maintaining consistent print quality, managing post-processing requirements and ensuring reproducibility of detailed designs.

Is additive manufacturing economically viable compared to traditional methods?

Additive manufacturing is more cost-effective for small to medium production runs of customised parts and intricate geometries, although it may be less economical for high-volume production of standard components.

Can additive manufacturing be used for mass production?

While additive manufacturing performs well in prototyping and limited-run production, recent process improvements have allowed for larger series production, given that part complexity and material selection are managed appropriately.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento