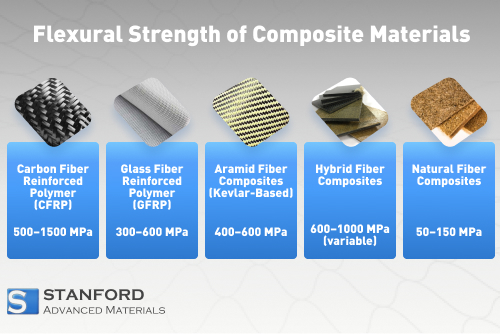

Flexural Strength of Composite Materials

Introduction

Composite materials consist of at least two distinct substances that are combined to enhance properties. In this review, we discuss how the materials resist bending loads.

Carbon Fiber Reinforced Polymer

Carbon Fiber Reinforced Polymer typically resists temperatures of approximately 500°C and possesses flexural strengths of about 1500 MPa. It is often utilised for constructing aircraft and high-performance automobiles. It exhibits significant strength while being lightweight. For instance, bicycles and racing cars employ this composite material to enhance performance. In structural applications, its bending resistance makes it a sought-after material. The carbon fibres are oriented to effectively resist stress. They produce a hard and strong material when combined with resin. Many designers rely on its high strength-to-weight ratio. The balance of flexural strength and thermal resistance renders this composite very suitable for demanding applications.

Glass Fiber Reinforced Polymer

Glass Fiber Reinforced Polymer operates efficiently at temperatures up to 300°C with a flexural strength of about 600 MPa. This composite is commonly used in construction and in wind turbine blades. It offers a satisfactory balance between cost and performance. The glass fibres provide high strength, and the resin effectively binds the structure. This material is applicable in boat hulls and in sports equipment. It is more affordable compared to carbon fibre composites. The performance figures make it an appropriate cost-effective option where extreme strength is not required. It is frequently used in numerous applications due to design engineers valuing its strength and ease of production during repairs or modifications.

Aramid Fiber Composites (Kevlar-Based)

Aramid Fiber Composites, including Kevlar-based types, perform well up to 400°C and can withstand flexural loads around 600 MPa. They are recognised for their toughness and good impact resistance. These materials are used in protective equipment and certain vehicle components. Kevlar composites are particularly suited for body armour due to their energy-absorbing capability. Their flexural strength is adequate for most moderate loading applications. The inherent fibre structure allows them to be flexible without a tendency to shatter easily. Such stability under stress makes them the preferred choice in safety-critical applications. They also respond to heat, thereby enhancing adaptability.

Hybrid Fiber Composites

Hybrid Fiber Composites are varied, with flexural strengths reaching up to 600°C and approximately 1000 MPa. Hybrid materials merge properties of multiple fibres to fine-tune performance. Typically, they involve a combination of carbon fibres and glass fibres. The objective is to achieve the optimal qualities of each material. Designers can customise the mixture based on specified rigidity or flexibility. Hybrid composites are found in sports equipment and electronic enclosures. Their versatility in design appeals to engineers who must consider cost against strength and weight. Such composites may become essential elements of innovative solutions in industries where pure carbon or pure glass fibre alone would not suffice.

Natural Fiber Composites

Natural Fiber Composites perform optimally at lower temperatures, up to around 50°C, and possess flexural strengths of approximately 150 MPa. These composites include fibres such as jute, hemp, or flax with a biodegradable resin. They provide an eco-friendly solution for applications in automotive interiors, packaging, and building panel markets. Although their performance is below that of synthetic products, their renewability and cost-effectiveness attract designers. The increasing interest in sustainable materials makes these composites appealing for further development. In less demanding applications where high temperatures or heavy loads are not an issue, natural fibre composites offer adequate performance with added environmental benefits.

Conclusion

Numerous composite materials exist to meet a variety of engineering applications. Each category has its benefits and drawbacks.

Carbon Fiber Reinforced Polymer is strong and heat resistant. Glass Fiber Reinforced Polymer is cost-effective and suitable for general use. Aramid Fiber Composites are resistant to impact and moderate bending loads. Hybrid Fiber Composites allow engineers to customise according to specific requirements. Natural Fiber Composites offer an environmentally conscious solution with reduced performance.

Frequently Asked Questions

F: What does flexural strength measure?

Q: It measures the resistance of a material against bending forces.

F: Can hybrid fibre composites be engineered?

Q: Yes, their properties can be varied by blending fibres of different types.

F: Are natural fibre composites suitable for high temperature?

Q: No, they are intended for use at low temperatures.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento