Hardness Comparison Chart of Metals, Alloys, and Ceramics

Introduction

Hardness is an important property when selecting materials for various applications. This guide examines the hardness of metals, alloys, and ceramics. Hard materials are utilised in heavy-duty applications, including tools and machinery. Softer materials may exhibit benefits such as flexibility and ductility.

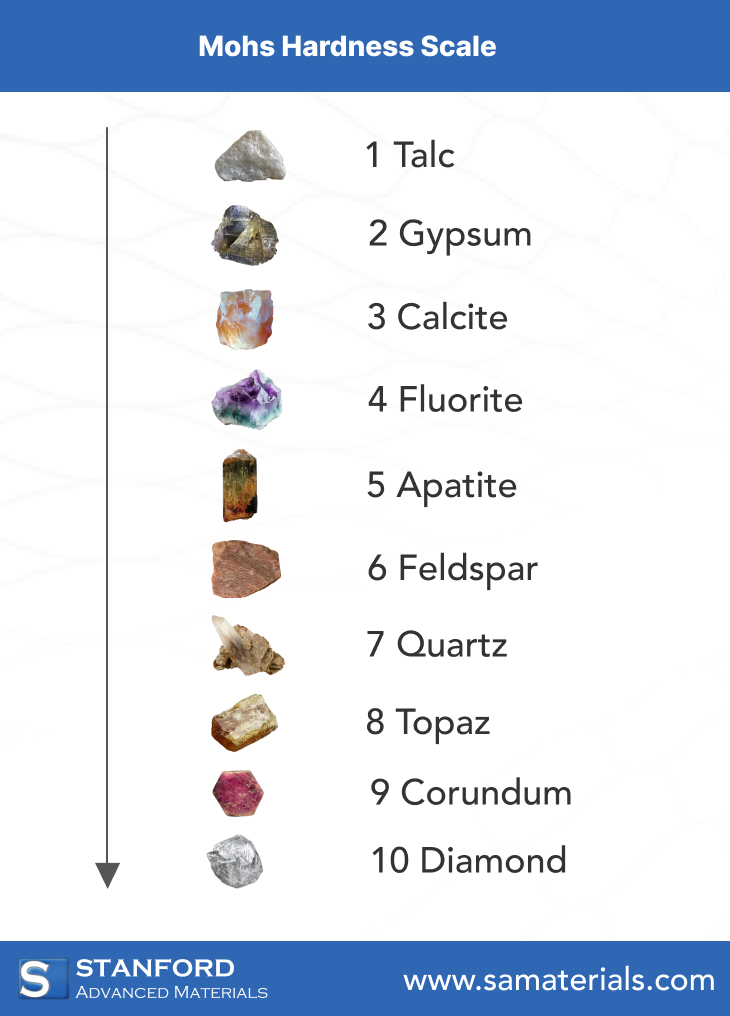

Mohs Hardness Chart

The Mohs hardness scale is one of the simplest methods to compare the hardness of minerals and materials. This scale ranges from one to ten, with a reading of one indicating the softest material, talc being a typical example. At the opposite end, a score of ten represents the hardest materials, with diamond known for having a Mohs rating of ten.

For metals and alloys, the Mohs scale provides a rough estimation of hardness. Many metals fall between three and five; for instance, pure iron scores around four. Alloys can achieve higher values due to their mixed composition. Ceramics often have higher scores, sometimes reaching up to eight. It is important to note that the Mohs scale is ordinal and does not quantify the differences in strength between materials. It only presents a rank order of hardness.

The scale is practical for everyday use. In the field, one can compare an unknown material with a set of standard minerals, aiding in the determination of whether the material can be employed in demanding tasks. For an experienced technician, this method is beneficial for a quick assessment when more precise tests are not available.

Further reading: Metal Hardness and the World's Strongest Metals

Vickers Hardness

The Vickers hardness test is a more accurate method used in laboratories. An indenter shaped like a diamond pyramid is pressed against the material. The test measures the size of the indentation left after the force is removed. The Vickers Hardness Number (VHN) provides a detailed measure of hardness.

In this test, the force and the size of the imprint are directly linked. The scale applies to a wide array of materials. For many metals, a higher VHN corresponds to improved resistance to deformation. Alloys typically display enhanced hardness compared to pure metals. In the case of ceramics, the values can be significantly high. Ceramics are acknowledged for their exceptional hardness but may exhibit brittleness.

A specific advantage of the Vickers test is its applicability for thin materials and coatings. A small indentation suffices to yield reliable hardness values. This method is commonly employed in quality control and research laboratories. Engineers value the data for its precision and repeatability.

Materials Hardness Comparison

When comparing hardness values, metals and alloys generally exhibit lower numbers than ceramics. Metals such as aluminium and pure iron typically display lower hardness. Their Vickers hardness numbers tend to fall within the range of 100 to 300 VHN. Alloys, particularly hardened steels, can have values approaching 800 to 1 000 VHN.

Ceramics, on the other hand, can achieve Vickers hardness values well exceeding 1 000. For example, tungsten carbide, a type of ceramic composite, often surpasses 1 500 VHN. This makes ceramics suitable for cutting tools and abrasives. Their elevated hardness, however, can lead to brittleness. A metal may bend prior to fracturing, whereas a ceramic can break suddenly when subjected to excessive load.

A side-by-side comparison of hardness charts proves beneficial for selecting the appropriate material. When a project demands durability and scratch resistance, a ceramic may be the optimal choice. For products requiring impact resilience, a metal or alloy may perform better. The working environment and application demands dictate which material is most suitable.

Engineers consider these comparisons when designing components. Tools, machine parts, and even everyday items gain benefit from the appropriate material choice. The hardness chart assists in this decision, ensuring the component endures under demanding conditions.

Conclusion

This guide has explored important methods for measuring hardness. The Mohs hardness scale provides a straightforward, ordinal ranking. The Vickers hardness test offers precise and repeatable data. Comparing metals, alloys, and ceramics reveals that each material type has its advantages and limitations. Metals and alloys are frequently selected for their toughness and ductility, while ceramics are valued for their scratch resistance and high hardness. Understanding these differences is essential for selecting the correct material for any application.

Frequently Asked Questions

F: What is the Mohs hardness scale used for?

Q: The Mohs scale ranks materials based on scratch resistance from one to ten.

F: How does the Vickers hardness test work?

Q: It measures the indentation size created by a diamond pyramid under a specified load.

F: Why are ceramics generally harder than metals?

Q: Ceramics possess a robust atomic structure, leading to higher resistance to deformation.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento