How Niobium Crucibles Are Used In Metallurgy

Introduction

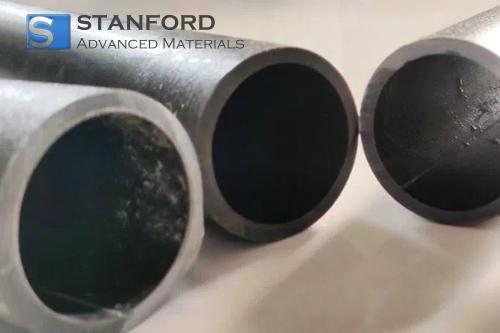

Crucibles are an essential tool in metallurgy; they contain molten metal during high-temperature processes. At every stage of metal processing, purity is required. Various metals are susceptible to impurities. A small impurity can alter the properties of an alloy. Consequently, niobium crucibles are used.

Niobium is generally selected for processing high-purity metals. It is not an ordinary metal but possesses distinct properties that make it better suited for high-temperature processing. When metals are exposed to high temperatures, most materials melt. Niobium crucibles withstand these conditions. When melting high-purity metals or alloys, maintaining stability is essential. Consequently, niobium is the material of choice. All these aspects are detailed in this article.

Key Features of Niobium Crucibles

Niobium crucibles have a high melting point and can be employed efficiently at temperatures exceeding 2 400 °C. In comparison, most alloys melt below 2 000 °C. The high melting point ensures that the crucible material does not mix with the molten metal.

Thermal stability is an important advantage. Even when subjected to temperature fluctuations, niobium maintains its structure. This results in fewer errors in the final metal product. In the processing of superconducting alloys, even a slight temperature fluctuation may cause inconsistencies. Niobium crucibles help to prevent this.

Niobium crucibles exhibit excellent resistance to oxidation and corrosion. If the inner material of a crucible reacts with molten metals or gases, chemical reactions may occur. Common materials begin to decompose. Niobium does not soften under these conditions because it forms a protective layer. This resistance reduces the risk of contamination.

Niobium also shows chemical inertness towards molten metals. In many processes, reactions between the crucible and the metal can compromise metal purity. Niobium does not react with most molten metals. Consequently, this inertness preserves the purity of the metal.

Advantages in Metallurgical Processes

The use of niobium crucibles helps ensure that contamination during alloy production is minimal. The crucibles are manufactured with such high purity that no impurities are introduced. Even a trace of another element can alter the physical properties of an alloy. Niobium crucibles help maintain a clean process.

They are also used in vacuum melting operations. Under such conditions, air removal is required to prevent oxidation. Niobium crucibles remain stable under vacuum or inert gas atmospheres without deterioration. Their stability under these conditions consequently leads to more consistent results. In vacuum induction melting, the integrity of the crucible is critical for producing high-quality alloys.

A long service life is a significant advantage. Niobium crucibles can be reused repeatedly without degrading performance. This durability reduces costs and the need for frequent replacement. Organisations using niobium crucibles appreciate their longevity, which makes them a cost-effective option. Given that reusability under extreme conditions is beneficial, niobium performs well in such environments.

Typical Applications

Niobium crucibles are used for melting superalloys. Superalloys are employed under extreme loads and at high temperatures. Examples include turbine blades for jet engines and components for rockets. In routine alloy production, there is a risk that crucibles made from less stable materials may introduce contaminants. Consequently, niobium crucibles reduce this possibility.

The melting of superconducting alloys is another important application. Superconducting alloys require strict purity to function properly. Even a minor impurity may affect their performance. The use of high-purity niobium crucibles is therefore appropriate because they do not introduce unwanted elements.

Niobium crucibles are also employed in vacuum induction melting. In this process, the environment is maintained to a high standard. Their reliable performance under vacuum conditions ensures that both the composition and properties of the alloy are not compromised. In electron beam melting, materials must withstand extreme conditions; niobium crucibles meet these requirements. Industrial entities have reported consistent production levels when using niobium crucibles in such processes.

Further Reading: All about superconducting niobium-titanium materials

Conclusion

Niobium crucibles are indispensable in ultra-high-purity metallurgy. They are engineered for melting processes at high temperatures and for maintaining thermal stability under extreme operating conditions. Their resistance to corrosion, oxidation and chemical reactions ensures that the purity of the metal is maintained throughout processing. In alloy production, purity is essential. Niobium crucibles help to maintain this standard. They are suitable for use in vacuum and inert atmospheres. Additionally, their long service life makes them both effective and economically viable. In summary, the durability and longevity of niobium crucibles make them a valuable tool in metallurgical processes.

Frequently Asked Questions

Q: Why is niobium used for crucibles?

A: Niobium exhibits resistance to corrosion and high temperatures, thereby maintaining metal purity during processing.

Q: What temperatures can niobium crucibles withstand?

A: They are suitable for temperatures up to approximately 2 400 °C and are appropriate for high-purity metallurgy.

Q: Are niobium crucibles reusable?

A: Yes, due to their durability and stability, they can be reused under extreme conditions.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento