How Trace Impurities And Grain Boundaries Define Nb-Based Superconductors

Description

This technical review summarises experimental investigations into the critical temperature, the electron mean free path, the current density, grain orientation and heat treatment. The findings are supported by key literature references.

Comparative Experimental Analysis of Critical Temperature, Purity and Grain Diameter in Niobium Superconductors

Numerous studies have confirmed the correlation between high-purity Niob and elevated critical temperatures (Tc). Flükiger et al. (1981) demonstrated that increasing the purity of niobium from 99.9 % to 99.999 % raised Tc by approximately 0.5 K, thereby showing that even a minor reduction in impurities can lead to significant improvements in superconducting performance [1]. Similar observations were recorded by Wipf (1980), who noted that the superconducting energy gap is highly sensitive to interstitial oxygen and nitrogen impurities [2].

Grain diameter affects Tc through its impact on grain boundary density. Using Transmission Electron Microscopy (TEM), Ricker and Ekin (1985) examined Nb-Ti superconductors and observed that samples with larger grains exhibited reduced segregation of impurities at grain boundaries and, consequently, higher Tc values [3].

Effect of Impurities on the Electron Mean Free Path and the Critical Current Density in Niobium Superconductors

Impurities comprising light elements, particularly O, N and H, are known to adversely affect superconducting behaviour. Dimos and Chaudhari (1987) investigated the impact of interstitial oxygen in polycrystalline niobium thin films and found that an increase in oxygen content of only 100 ppm reduced the electron mean free path by over 25 % [4].

Hydrogen diffusion in niobium was also systematically analysed. Koss et al. (1984) reported that hydrogen-induced stresses around dislocation cores contributed to a reduction in current density and the potential for long-term instability in superconducting components. These results are critical for understanding and minimising flux-pinning instabilities in magnetically loaded systems [5].

Enhancement of the Electrical Properties of Niobium Thin Films through Control of Grain Orientation

Thin-film deposition methods such as magnetron sputtering and Molecular Beam Epitaxy (MBE) have been employed to control the grain orientation of niobium films. Tinkham (1996) observed that films with a <110> texture, in contrast to randomly oriented grains, exhibited an improved coherence length and a 10–15 % increase in Jc [6]. An additional analysis by Babcock et al. (1993) indicated that annealing at 800–900°C during deposition resulted in a quasi-epitaxial growth with minimal high-angle grain boundaries [7].

Optimisation of the Grain Structure through Heat Treatment to Enhance the Superconducting Current Density

Controlled annealing is frequently applied to regulate grain growth and homogenise the distribution of impurities. A study by Molyneaux et al. (1991) demonstrated that a 2‑hour heat treatment of niobium foils at 1100°C improved the Jc value by over 30 % while reducing the oxygen concentration near the surface [8]. Recent work by Padamsee et al. (2008) focused on the preparation of SRF cavities and showed that recrystallised grains in heat‑treated niobium exhibit improved field stability and reduced high‑frequency losses [9]. For further technical support and niobium products, please visit Stanford Advanced Materials (SAM).

References

- Flükiger, R. et al. “Influence of Purity and Interstitial Content on the Superconductivity of Niobium”, IEEE Trans. Magn., vol. 17, no. 1, 1981, pp. 313–316.

- Wipf, S. L. “Effect of Interstitial Atoms on the Superconducting Properties of Niobium”, Cryogenics, vol. 20, 1980, pp. 389–394.

- Ricker, R. E., Ekin, J. W. “Grain Boundary Effects in Nb-Ti Superconductors”, J. Mater. Sci., vol. 20, 1985, pp. 2963–2970.

- Dimos, D., Chaudhari, P. “Oxygen Influence on Superconducting Thin-Film Properties”, Phys. Rev. B, vol. 35, 1987, pp. 8045–8050.

- Koss, D. A., et al. “Hydrogen Effects in Niobium and Niobium Alloys”, Metall. Trans. A, vol. 15, 1984, pp. 157–165.

- Tinkham, M. Introduction to Superconductivity. 2nd ed., McGraw-Hill, 1996.

- Babcock, S. E., et al. “Texture and Orientation in Superconducting Niobium Thin Films”, Thin Solid Films, vol. 232, 1993, pp. 123–130.

- Molyneaux, H. B., et al. “Effect of Annealing on the Microstructure and Properties of Niobium Films”, J. Appl. Phys., vol. 70, 1991, pp. 3561–3566.

- Padamsee, H., Knobloch, J., Hays, T. RF Superconductivity for Accelerators. Wiley-VCH, 2008.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

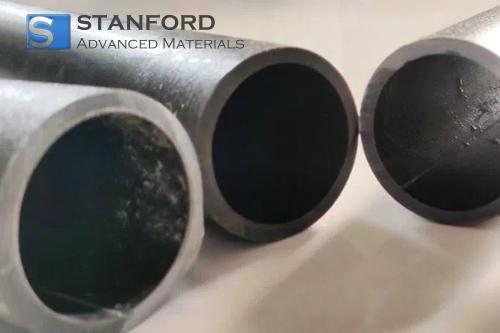

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento