Platinum: Element Properties And Uses

Platinum (Pt) is a dense, corrosion-resistant, silvery-white metal used in jewellery, catalytic converters, and medical devices. It is highly durable, malleable, and valued for its industrial and investment applications.

Introduction to the Element

One of the most intriguing elements on the periodic table, platinum is rare and has several remarkable properties. Platinum is known for its inertness and resistance to corrosion. Platinum was discovered in the 18th century by European scientists who were amazed and puzzled by its remarkable properties. This element has since become a status symbol in jewellery and a crucial component in many technological applications.

Chemical Properties Description

Platinum has a number of chemical properties that make it an essential element in many chemical reactions. This element is highly inert, and this is why it is often used as a catalyst in chemical reactions. It retains its shape and does not readily combine with other elements, even in conditions that are likely to cause other metals to oxidise.

Platinum also has a remarkable ability to resist high temperatures and acids. This makes it a material of choice in extreme conditions. Its inertness and high resistance to corrosion ensure that it continues to function well even after prolonged use in industrial applications.

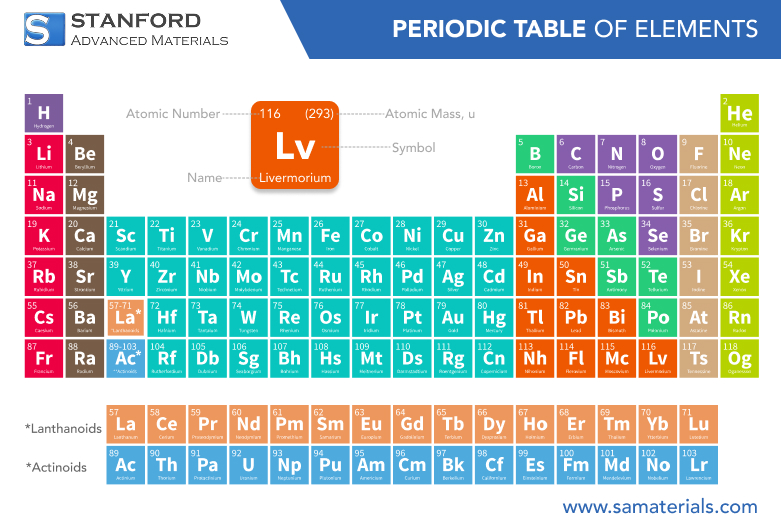

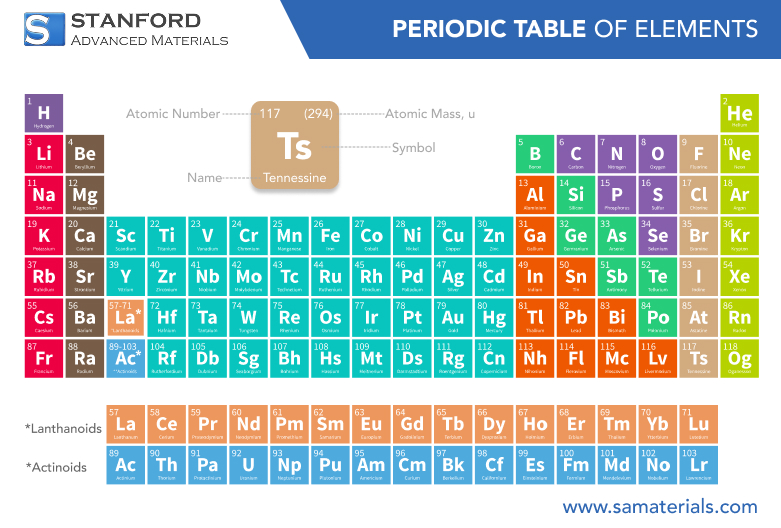

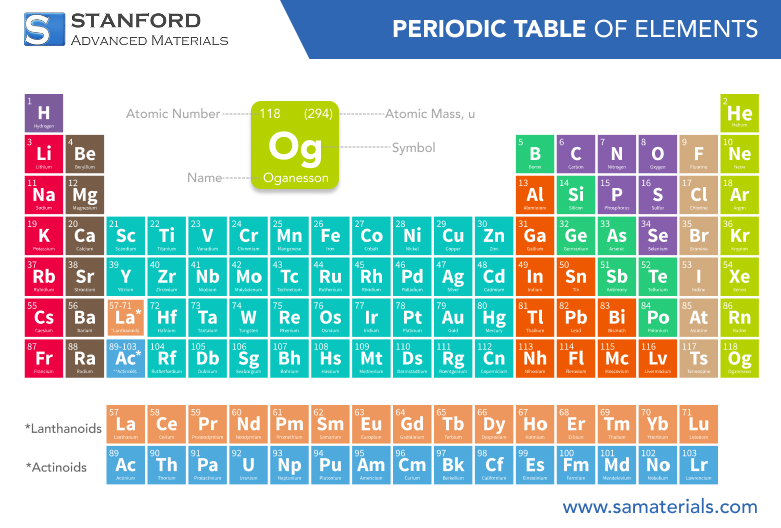

Physical Properties Data Table

|

Property |

Value |

|

Atomic Number |

78 |

|

Atomic Weight |

195.08 g/mol |

|

Density |

21.45 g/cm³ |

|

Melting Point |

1768.3 °C |

|

Boiling Point |

3825 °C |

For more information, please check Stanford Advanced Materials (SAM).

Key Uses of Platinum

Platinum is a rare precious metal with desirable properties such as stability, catalytic ability, and resistance to heat and corrosion.

- Its primary use is in the automotive industry, where catalytic converters containing platinum minimise the emission of dangerous pollutants such as nitrogen oxides and carbon monoxide.

- In the jewellery industry, platinum is highly prized for its natural white lustre and resistance to tarnish, which makes it suitable for use in high-end jewellery intended for long-term wear.

- Platinum is also used as an industrial catalyst in chemical reactions such as fertiliser, silicone, and nitric acid synthesis.

- In the electronics industry, platinum is used for its ability to withstand extreme temperatures and is employed for sensor components, hard drive coating, and spark plug manufacturing.

- In medicine, its biocompatibility makes it suitable for chemotherapy drugs such as cisplatin as well as pacemakers and stents.

- In the energy sector, platinum is used as an industrial catalyst in hydrogen fuel cells.

- Platinum is also used as an investment metal and in aerospace and glass manufacturing due to its high melting point and inertness.

Preparation Methods

The methods of preparation of platinum include a number of steps, which help in the transformation of the raw ore into the refined metal. Platinum is generally extracted from ore containing a mixture of platinum group metals. The steps involved in the extraction of platinum include mining, where the ore is blasted and later crushed and milled. Subsequently, concentration methods are applied, which include flotation and smelting.

After the extraction of platinum, a series of steps are applied for the refinement of the metal. The refined platinum is typically prepared through a series of chemical and electrolytic treatments. These methods of preparation ensure that the refined platinum meets the high standards required for its application.

Frequently Asked Questions

What are the primary applications of platinum?

Platinum is used in catalytic converters, jewellery, laboratory equipment, and high-performance electronic components.

How is platinum typically extracted from its ores?

The extraction process involves mining, crushing, milling, flotation, and smelting, followed by chemical and electrolytic refining.

Why is platinum favoured in industrial catalytic processes?

Its high resistance to corrosion, unreactive nature, and ability to withstand extreme conditions make it an ideal catalyst.

What makes platinum a valuable material in the jewellery industry?

Its lustrous appearance, durability, and resistance to tarnish make it a preferred choice for high-end jewellery.

How do the preparation methods affect the quality of platinum?

Efficient extraction and refining techniques ensure high purity and consistency, which are critical for both industrial and decorative uses.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

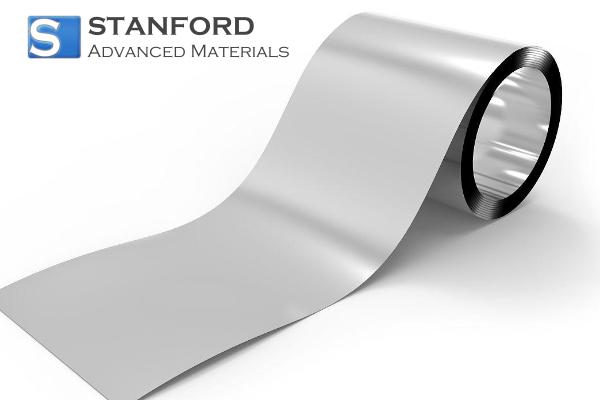

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento