Porosity: Types And Measurement

Meaning of Porosity

The porosity of a material is defined as the ratio between the volume of the voids and the total volume. It is a quantity that measures how much empty space is contained in a substance, and often greatly influences many of the physical properties of materials. High porosity means high levels of void spaces, reflecting a range of properties including strength, permeability, and fluid storage capacity.

Types of Porosity

There is a variety of porosity types, each with different characteristics and origins. The main types of porosity are:

Open Porosity:

Porosity can be defined as a condition whereby the pores are open and allow the passage of fluids or gases through a material. Porosity is especially expected in materials such as rocks and ceramics, where permeability is important.

Examples: Sponges, certain rocks (such as sandstone), and some synthetic foams

Closed Porosity:

Definition: Closed porosity is when pores are isolated and not connected to the others. Such pores do not allow fluids to pass through them and can be found in glass and some types of foam.

Example: Certain rubber and ceramic materials, which have the pores enclosed inside without interconnectivity among them.

Total Porosity:

Definition: The total porosity is the ratio of the volume of all pores, whether open or closed, to the total volume of the material. This gives an indication of the overall porosity and not necessarily a measure of the ability of the material to allow fluid or gas movement.

Example: Total porosity of soil samples, in which both the connected and disconnected pores are considered.

Effective Porosity:

Definition: That part of the total porosity that is interconnected and through which fluid or gas can pass. Effective porosity is one of the most important factors when dealing with the flow of fluids within materials like rocks or soils.

Example: Effective porosity in aquifers which determines how the groundwater can travel through the rock formations.

Measurement of Porosity

The exact measurement of porosity is of paramount importance in various scientific and industrial applications. Porosity is determined by several methods, each suited to different materials and pore sizes:

• Mercury Intrusion Porosimetry: Force mercury into pores under controlled pressure, measuring pore size distribution and total porosity.

• Gas Adsorption-BET Method: Involves the use of gas molecules adsorbing on the surface of the material, thereby giving information about surface area and pore size.

• Optical Microscopy: Visualises and measures pores directly, using high-resolution imaging techniques.

Methods of Measuring Porosity

|

Measurement Technique |

Suitable For |

Key Features |

|

Mercury Intrusion |

Wide pore sizes |

Measures pore volume and size |

|

Gas Adsorption (BET) |

Small to medium pores |

Provides surface area and porosity |

|

Optical Microscopy |

Visible pores |

Direct visualisation of pore structure |

For more information, please visit Stanford Advanced Materials (SAM).

Frequently Asked Questions

What is porosity?

Porosity refers to the measure of the void spaces within a material and is expressed as a percentage of total volume.

Why is porosity important?

Porosity affects the material's properties, such as strength, permeability, and the capability to store fluids, and thus is an important characteristic in geology and engineering.

How does porosity differ from permeability?

Porosity is defined as the volume of void space that exists in a material, whereas permeability describes how easily fluids can flow through those spaces.

What factors affect the porosity of a material?

Among these factors are the composition of the material, the size and distribution of its pores, and the processes it has undergone during formation.

Can porosity in materials be changed?

Yes, porosity can be adjusted by compaction, heat treatment, or chemical alteration to give desired properties.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

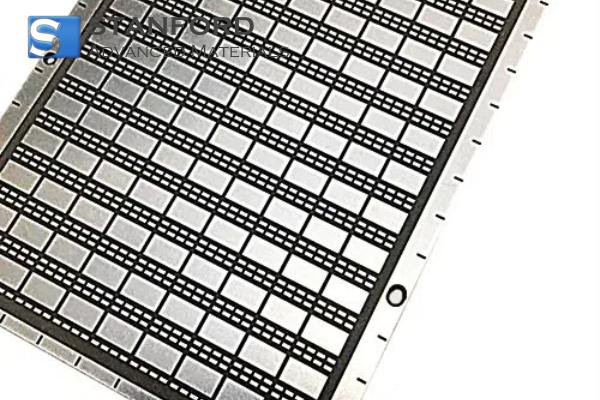

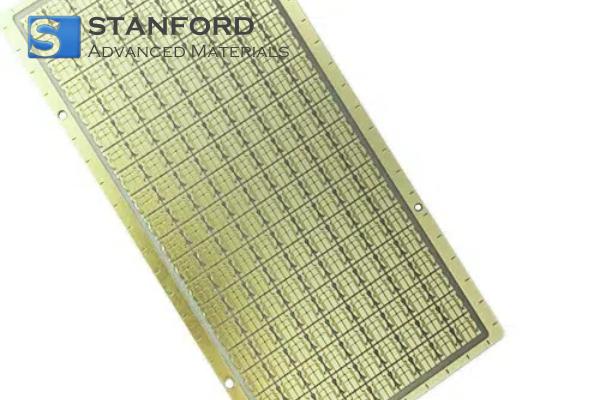

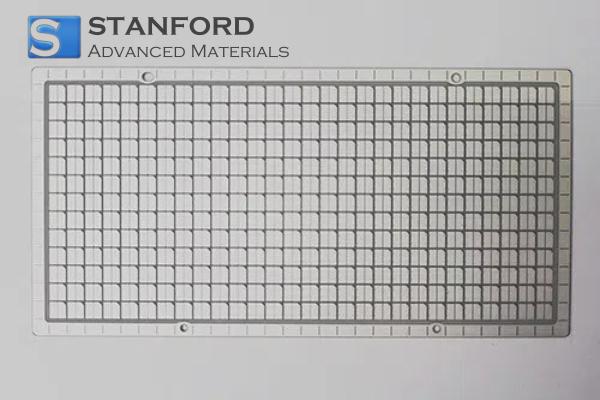

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento