Types Of Mechanic Strains

Description of Strain

Strain is a dimensionless measure of deformation representing the displacement between particles in a material body relative to a reference length. It quantifies how much a material stretches or compresses when subjected to external forces.

Types of Strain

Tensile Strain

Tensile strain occurs when a material is stretched or elongated. It is characterised by an increase in length along the direction of the applied force.

Compressive Strain

Compressive strain happens when a material is compressed or shortened. It involves a decrease in length under the influence of compressive forces.

Shear Strain

Shear strain is the deformation resulting from forces applied parallel to the material's surface, causing layers to slide relative to each other.

Volumetric Strain

Volumetric strain refers to the change in volume of a material when subjected to uniform pressure, affecting all dimensions.

|

Type of Strain |

Description |

Common Applications |

|

Tensile Strain |

Stretching or elongation of material |

Cable manufacturing, bridges |

|

Compressive Strain |

Compression or shortening of material |

Pillars, building supports |

|

Shear Strain |

Sliding deformation parallel to force direction |

Shear joints, mechanical gears |

|

Volumetric Strain |

Change in volume under uniform pressure |

Hydraulics, material testing |

Units of Strain

Strain is a dimensionless quantity, meaning it has no units. It is often expressed as a ratio or percentage, such as millistrain (mε) where 1 mε = 10⁻³ strain.

Stress vs Strain

While both stress and strain relate to forces applied to materials, they describe different aspects:

Stress is the internal force per unit area within a material that arises from externally applied forces. It is measured in units such as Pascals (Pa).

Strain measures the resulting deformation or displacement due to the applied stress. It is dimensionless and indicates how much a material deforms in response to stress.

Factors Affecting Strain

Several factors influence strain in materials, including:

- Material Properties: Different materials have varying elasticity and ductility, affecting how they strain under force.

- Temperature: Elevated temperatures can make materials more pliable, altering their strain response.

- Rate of Loading: Rapid application of force can lead to different strain behaviours compared to gradual loading.

Applications of Strain Mechanics

- Structural Engineering: Strain mechanics aids in designing buildings, bridges, and other structures to ensure they can handle deformation without failure.

- Material Testing: Strain measurements are crucial in testing the strength and ductility of materials during the development of new alloys and composites.

- Manufacturing: Processes like forging, extrusion, and rolling rely on controlled strain to shape materials effectively.

- Failure Analysis: Understanding strain aids in determining the cause of material failures, particularly when materials undergo excessive plastic deformation or fracture.

Frequently Asked Questions

What is the primary difference between stress and strain?

Stress measures the internal force per unit area within a material, while strain quantifies the resulting deformation or displacement due to that stress.

Why is strain considered dimensionless?

Strain is a ratio of deformation to the original length, cancelling out units and making it dimensionless.

How is tensile strain measured in materials?

Tensile strain is commonly measured using strain gauges that detect changes in electrical resistance as the material stretches.

Can strain be both positive and negative?

Yes, tensile strain is positive, indicating stretching, while compressive strain is negative, indicating compression.

What factors can influence the amount of strain in a material?

Material properties, temperature, and the rate at which force is applied are key factors that affect the amount of strain in a material.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

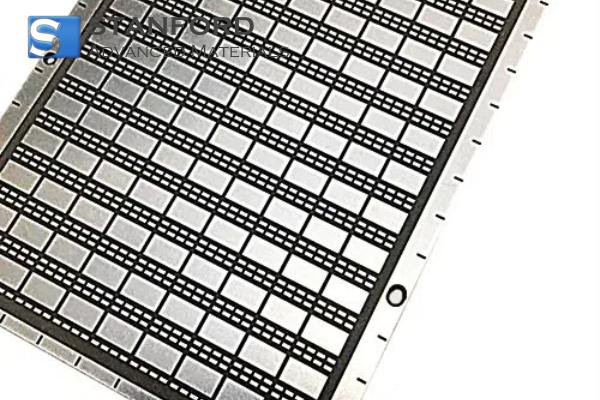

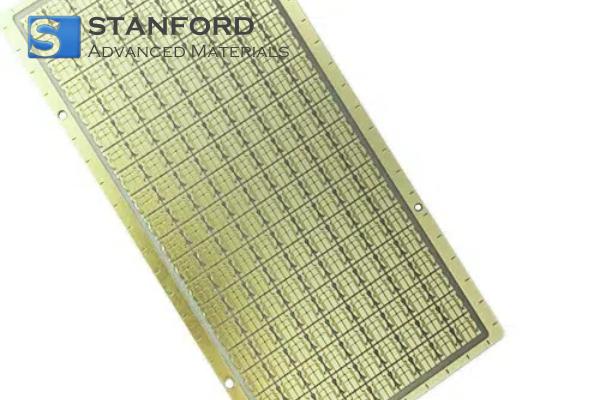

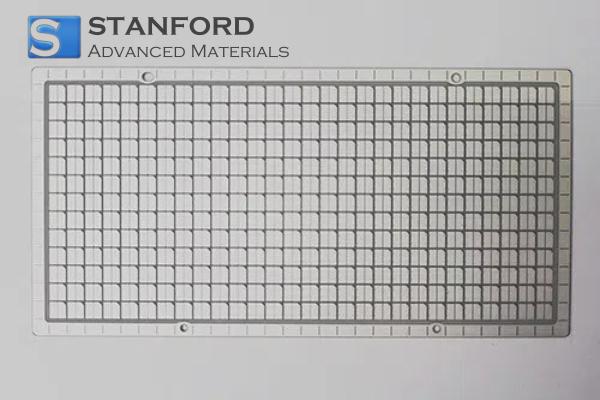

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento