What Are Aluminum Master Alloys?

Introduction

Aluminium master alloys are a key part of many metal products. They are used to adjust the properties of aluminium castings. In foundries and mills, these alloys help control strength, fluidity, and workability. Their role is very important in modern metal processing.

What Are Aluminium Master Alloys?

Aluminium master alloys are mixtures of pure aluminium and specific alloying elements. These elements include copper, silicon, magnesium, and zinc. The idea is to add a high percentage of an element to a small amount of aluminium. This mixture is then introduced into a larger melt of aluminium. The purpose is to tailor the final alloy's properties.

For example, an aluminium-silicon master alloy typically contains 15% to 25% silicon. This is used in casting because silicon improves fluidity. With better fluidity, the metal fills moulds more easily. This leads to smoother surfaces and fewer defects in cast parts. In a similar way, aluminium-copper master alloys often have about 10% to 20% copper. These are used to enhance strength in the final product.

When producing automotive parts, foundries may add a master alloy with a high magnesium content. Magnesium improves the strength and resistance of the final aluminium alloy. In one instance, a plant used a magnesium-rich master alloy and reported better tensile strength in their engine blocks. The benefits are real and measurable.

Aluminium master alloys can also save time. When producing large volumes of metal parts, accuracy is very important. Instead of adding small amounts of pure alloying elements repeatedly, a master alloy is added once to reach the desired level. This leads to fewer errors and a more reliable process. It is also a cost-effective solution. The master alloy is made under controlled conditions. This means that its composition is precise and repeatable.

Let us take the aluminium-zinc master alloy as another example. Zinc can improve the stress resistance of aluminium. When a master alloy with a high zinc content is added, the final alloy contains the right concentration for the job. In the aircraft industry, alloys with zinc are chosen because they provide a good balance of weight and strength. Even though the aluminium is light, the mechanical properties of the final alloy meet high standards. I recall an application where a zinc-rich alloy helped reduce unwanted vibrations in a component.

The process of producing master alloys is established and reliable. A foundry heats pure aluminium in a furnace. The alloying element is introduced. The mixing is even and thorough. The master alloy is poured into moulds to cool. Once it solidifies, it is cut into pieces. These pieces can later be added to the melt at the appropriate proportions. This method ensures that the final mixtures are stable and meet the design requirements.

There are some other benefits as well. Master alloys reduce the risk of contamination. Small amounts of impurities can affect the whole batch if added individually. With master alloys, the better control of chemistry leads to a purer product. This is vital when producing items where quality cannot be compromised.

It is also worth noting that using a master alloy simplifies recalibration. When an error occurs, a small volume of master alloy can be added to correct the composition. This is easier than re-melting the entire batch. Precision is maintained with minimal waste. Many plants use this method because it is practical and efficient.

I often mention that compatibility is key. The base aluminium and the alloying elements must work well together. An imbalance might lead to unwanted phases or defects. For instance, too much of an element might make the aluminium brittle. That is why precise measurement is critical. In practice, after the master alloy is added, standard tests are conducted. These tests ensure that the final composition is as planned.

When speaking with newer engineers, I underline that the science behind these alloys is well established. Decades of trial and error have led to specific recipes. For example, aluminium-magnesium alloys are widely used in beverage cans. They provide the perfect balance between weight and durability. The master alloy assists in reaching the precise magnesium level. This gives cans the strength needed to hold carbonated beverages without being too heavy.

Properties of aluminium master alloys depend on the chosen alloying element. They are known for their homogeneity. This means that each small piece of master alloy has a consistent composition. Consistency is very important in large-scale production. With each addition, the metal melt gradually reaches a stable and desired composition.

Another key benefit is ease of handling. The master alloys are produced in controlled batches. This provides industries confidence in the raw material. It is a simple step that makes a large impact on the finished product. For instance, a steel foundry that uses aluminium master alloys can control the microstructure of the final metal. The result is a product that meets specific design needs.

A real-life case involves the production of engine blocks. In such a process, aluminium master alloys containing copper and magnesium were added. The final alloy showed improved heat resistance. In automotive applications, this is crucial because the metal must operate under high stress and temperature. The use of master alloys helped the manufacturer meet quality tests and performance standards.

Conclusion

In summary, aluminium master alloys are very useful in modern industrial applications. They help in tailoring the properties of aluminium alloys. Their role in improving strength, workability, fluidity, and reliability cannot be overemphasised. Applications are found in the automotive industry, aerospace, beverage packaging, and many other areas. For more master alloys, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: What are aluminium master alloys?

Q: Aluminium master alloys are mixtures of aluminium with high levels of an alloying element used to adjust the properties of cast aluminium alloys.

F: How do aluminium master alloys benefit the production process?

Q: They improve fluidity, strength, and consistency in the final product, reducing errors and ensuring a reliable manufacturing process.

F: Can master alloys adjust properties in large-scale production?

Q: Yes, they allow controlled additions to achieve precise alloy compositions, crucial for maintaining quality in large-scale manufacturing.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

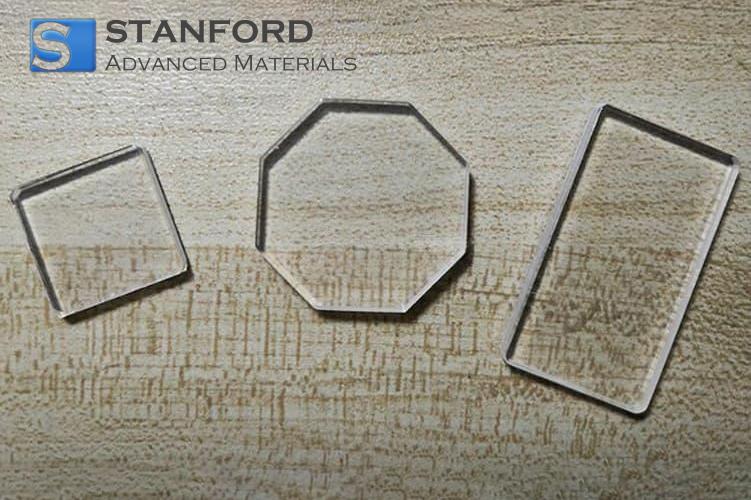

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

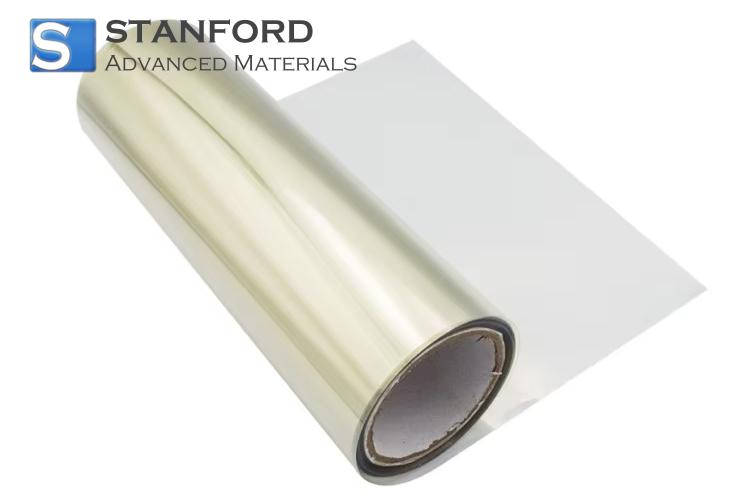

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento