Why Carbon Fiber Is The Material Of The Future

Carbon fibre is rapidly becoming one of the most sought-after materials in modern manufacturing, ranging from high-end bicycles to advanced electronics.

But what exactly is carbon fibre, and why is it so special? We will explore what carbon fibre is, its unique qualities, and how it is being used. By the end, you will understand why carbon fibre is often considered the material of the future.

What Is Carbon Fibre?

Carbon fibre is a substance formed from fine fibres composed of carbon atoms in a crystalline form. The carbon fibre is often processed by heating so-called precursor materials, including polyacrylonitrile (PAN), rayon, and petroleum pitch, at very high temperatures in the absence of air. The procedure is called pyrolysis and results in the removal of non-carbon material from the precursors, producing long-chain carbon atoms. The carbon fibres produced are very light in mass and possess high strength and rigidity properties.

The fibre is generally combined with a resin material such as epoxy to create a composite. The composite is widely used to manufacture lightweight and strong structures. The composites are mouldable and are generally made in different shapes and sizes as required by the applications. Carbon fibres are widely valued for their strength-to-weight ratio properties, corrosion resistance, and thermal resistance.

What Makes Carbon Fibre So Special?

The attractiveness of carbon fibre is based on its numerous properties:

1. High Strength-to-weight Ratio

Carbon fibre materials have one of the strongest strength-to-weight ratios. Carbon fibre materials are five times stronger than steel but lighter. This implies that carbon fibre materials possess the same strength or even greater strength than steel. However, the carbon fibre materials are lighter than steel. It is highly beneficial to have the same strength at a lighter weight because this aspect can significantly benefit the same industries.

2. Stiffness

Carbon fibre materials are also extremely stiff and resist the effects of pressure. In other words, they resist significant bending or flexing when subjected to pressure. This characteristic makes carbon fibre ideal for the manufacturing of aircraft wings or other sporting equipment such as tennis racquets and golf clubs. In addition to durability, carbon fibres also retain their shape when under pressure.

3. Corrosion Resistance

In contrast to metals, carbon fibres possess the natural ability to resist corrosion, making them especially suited to harsh conditions where the material may be exposed to water, chemical substances, or high temperatures. Carbon fibres, for instance, are especially suited to applications involving boats, where they do not oxidise like steel or aluminium.

4. Thermal Stability

Carbon fibre composites do not undergo degradation due to high temperatures. Certain types of carbon fibre can withstand temperatures above 300° C (572° F), and as such, they find many applications as engine components. This is particularly true for both automobiles and aircraft.

5. Versatility

It is possible to shape it in complex forms and designs, and this is a quality that is hard to match in other materials. This has made it a very popular material for various industries ranging from consumer electronics to aerospace exploration.

What Are the Uses of Carbon Fibre?

It is applied in many fields, given its outstanding strength and durability. Some of the most notable uses include the following:

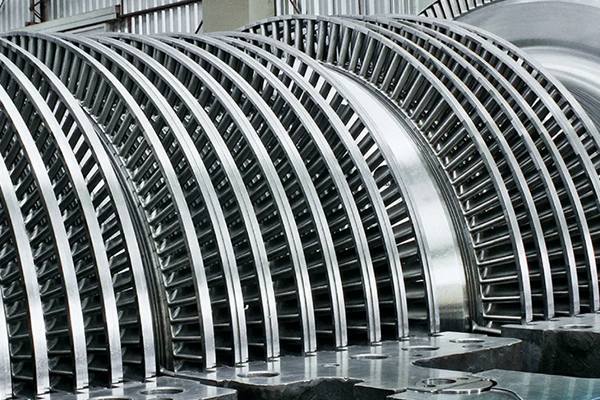

1. Aerospace and Aviation

The aerospace industry has widely adopted carbon fibre, which is in increasing demand. Aircraft manufacturers have utilised carbon fibre composites in many key structural parts such as wings, fuselage, and others to reduce weight and thereby increase fuel efficiency. This material is able to withstand high speed, strong pressure, and extreme temperature; thus, it is perfect for flying.

2. Automobile Industry

Carbon fibre is fast finding a wider application in the automotive industry, with a particular emphasis on high-performance sports cars and electric vehicles. The lightweight nature of carbon fibre improves fuel economy in EVs while also enhancing the performance of traditional petrol-powered vehicles by reducing overall weight.

3. Sports Equipment

Carbon fibre also finds wide applications in high-end sports equipment manufacturing, such as bicycles, tennis rackets, and golf clubs. The toughness combined with lightweight properties has made carbon fibre the preferred material for athletes where speed and precision are required.

4. Medical Devices

In healthcare, carbon fibre is utilised in making prosthetic devices, medical equipment, as well as imaging equipment. This is because it is light, which is comfortable for patients. In addition to that, it is radiolucent.

5. Consumer Electronics

Carbon fibre is increasingly finding its applications in consumer electronics such as smartphones, laptops, etc. The hardness as well as the lightweight nature of carbon fibre provides the necessary strength and portability.

Carbon Fibres and Other Materials

When carbon fibre is considered alongside other traditional materials such as steel, aluminium, and plastics, it is evident that it has some advantages. Here's a comparison of carbon fibre with some of the other commonly used materials:

• Carbon Fibre vs. Steel: Carbon fibre is more strenuous than steel based on weight, and it is most suitable to use when strength is required without additional weight. Steel, however, is more economical and feasible to produce on a mass scale. Even though carbon fibre performs better, it is more expensive to produce and requires more complex manufacturing processes.

• Carbon Fibre vs. Aluminium: Although lighter than steel, it does not match carbon fibre in strength-to-weight ratio. Also, it is more prone to corrosion than carbon fibre. While their cost is lower, carbon fibre boasts better durability and resistance to wear.

• Carbon Fibre vs. Plastic: Plastics are low in cost and light in weight but are considerably less strong and less durable when compared to carbon fibre. Carbon fibre composites are much more rigid, and their resistance to temperature and corrosion extends their applications to more demanding conditions. For more advanced materials and their applications, please check Stanford Advanced Materials (SAM).

FAQs

- Why is carbon fibre so expensive?

Carbon fibre is expensive due to the complex and energy-intensive manufacturing process. The raw materials used to make carbon fibre are costly, and the production process requires high precision, contributing to its overall cost. - Can carbon fibre be recycled?

Yes, carbon fibre can be recycled, but the process is still evolving. Researchers are working on developing more efficient methods to break down and reuse carbon fibre materials, which could help reduce costs and environmental impact. - Is carbon fibre stronger than steel?

In terms of strength-to-weight ratio, carbon fibre is stronger than steel. However, steel is more durable and performs better under certain conditions, particularly in terms of toughness and impact resistance. - How long does carbon fibre last?

Carbon fibre is incredibly durable and can last for decades if properly maintained. It is resistant to corrosion, which helps prolong its lifespan in harsh environments. - What are the environmental impacts of carbon fibre production?

The production of carbon fibre involves high energy consumption and can result in carbon emissions. However, efforts are being made to make the production process more sustainable, including recycling initiatives and improved manufacturing techniques.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento