Case Study: How SAM managed a Calcium Oxide target cracking incident

Background

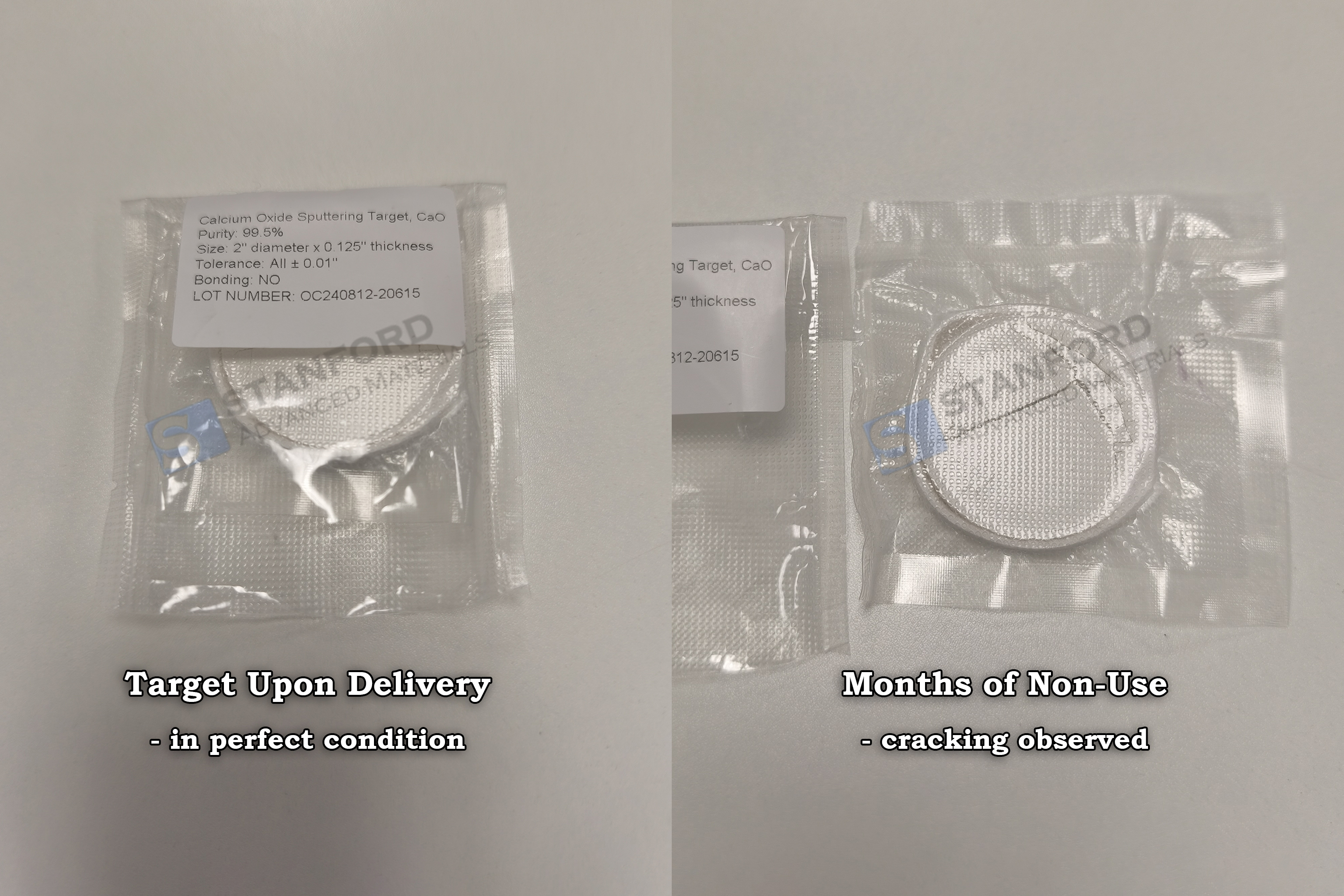

A customer contacted Stanford Advanced Materials (SAM) regarding an issue with a Calcium Oxide (CaO) sputtering target. The target arrived vacuum‐sealed, unopened and stored in a plastic container.

Months later, without being used, the customer observed cracks on the target’s surface. The customer confirmed that the packaging was never opened, that the target was maintained at room temperature and that handling remained minimal. A replacement was then requested.

Technical Review & Findings

Our engineering and quality control teams investigated the incident in detail. Based on the customer’s description, photographs and internal manufacturing records, SAM determined the following:

-

The product was packaged in accordance with SAM’s standard for sensitive materials. It was vacuum‐sealed, cushioned and moisture‐isolated.

-

No indications of handling error or improper storage conditions were observed.

-

Calcium Oxide (CaO) is hygroscopic. It absorbs moisture from the air when seal integrity is compromised or during extended storage.

-

The customer did not transfer the product into a dry storage environment. The target was not used promptly after delivery.

SAM concluded that the cracking was not caused by a manufacturing or packaging defect. It resulted from the known moisture sensitivity of CaO combined with delayed usage.

Our Response

At Stanford Advanced Materials, we supply both materials and technical support.

Although the issue resulted from CaO’s inherent moisture sensitivity and extended storage, SAM exceeded its standard policy to prevent disruption to the customer’s research. The team analysed the situation and provided a practical solution at minimal cost.

-

A replacement CaO target was provided free of charge.

-

At the customer’s request, the new target was bonded to a backing plate. This bonding enhanced mechanical support and reduced the risk of cracking.

-

The customer incurred only the bonding cost.

"The replacement target with bonding meets our requirements. Thank you. We will follow your handling guidelines," replied the client upon receiving the new piece.

Best Practices & Customer Guidance

Recommendations for Users:

-

Store all hygroscopic materials, such as CaO, in a dry box immediately after receipt.

-

Use the materials within a limited timeframe, preferably within days, to prevent environmental degradation.

-

For fragile ceramics, bond the material to a backing plate for additional mechanical support.

SAM's Internal Upgrades:

-

SAM enhanced its packaging standards:

-

Double vacuum‐sealed bags

-

A PP box containing desiccant

-

Labels indicating moisture and shock protection

-

-

SAM is compiling a reference list of sensitive materials. The teams have received training in line with upcoming guidelines.

-

Inspection policies were revised to limit the exposure of fragile or hygroscopic items before use.

Why Customers Trust Stanford Advanced Materials

This case demonstrates why leading research institutions and industrial laboratories trust SAM:

-

SAM understands the complexities of advanced materials and provides technical explanations.

-

SAM accepts responsibility for customer experience, even when problems arise from external factors.

-

SAM continuously revises its service protocols, packaging methods and technical documentation.

SAM’s commitment extends beyond material delivery. We work with customers to ensure that materials perform according to specifications. For enquiries regarding material supply and technical support, please contact Stanford Advanced Materials.

Are you ready to work with a materials supplier that supports every shipment?

Contact us today.

Also, view our sputtering target category here.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento