Case Study: Cracking of Alumina Crucibles in High-Temperature Dehydration

Introduction

A customer reported complete failure of a batch of large alumina crucibles during high-temperature dehydration operations. The crucibles, originally designed as insulation components, were used to hold powder materials during heating. Exposure to rapid temperature changes and steam resulted in fracture of the crucibles.

After reviewing the customer's process, engineers at Stanford Advanced Materials (SAM) identified thermal shock in a humid environment as the root cause. Alumina, despite being highly temperature-resistant, is not ideal for applications involving steam and rapid heating. SAM proposed several alternative materials, ultimately assisting the customer in transitioning to a solution with enhanced thermal stability.

Background

The customer had been using high-purity alumina crucibles, benefiting from their high thermal resistance (up to 1 750°C). However, in practice, the crucibles were exposed to a high-temperature furnace atmosphere containing substantial amounts of steam. The process required heating powdered material above 1 000 °C to expel moisture.

This setup introduced two primary stress factors:

-

High thermal gradients resulting from rapid heating and cooling

-

Regular contact with water vapour, which behaves differently with some ceramics

Although alumina possesses good chemical and mechanical properties, its poor thermal shock resistance—particularly in humid conditions—makes it susceptible to cracking. The customer approached us seeking a crucible that would withstand both heat and humidity without compromising structural integrity.

Clarifying the Application Environment

By maintaining open communication with the customer's technical team, SAM gathered extensive information regarding the process:

- Furnace Conditions: High-temperature ramps, exceeding 1 000 °C, with continuous water vapour present

- Functional Role: Crucibles were used not only as containers but also as active process vessels in an ongoing dehydration operation

- Failure Pattern: Cracks and catastrophic failures began appearing in initial heating cycles

- Material Requirements: Strength under temperature stress, thermal shock resistance, and chemical stability in steam

Consequently, it became apparent that standard alumina was being pushed beyond its design limits in this specific application.

Material Comparison and Selection

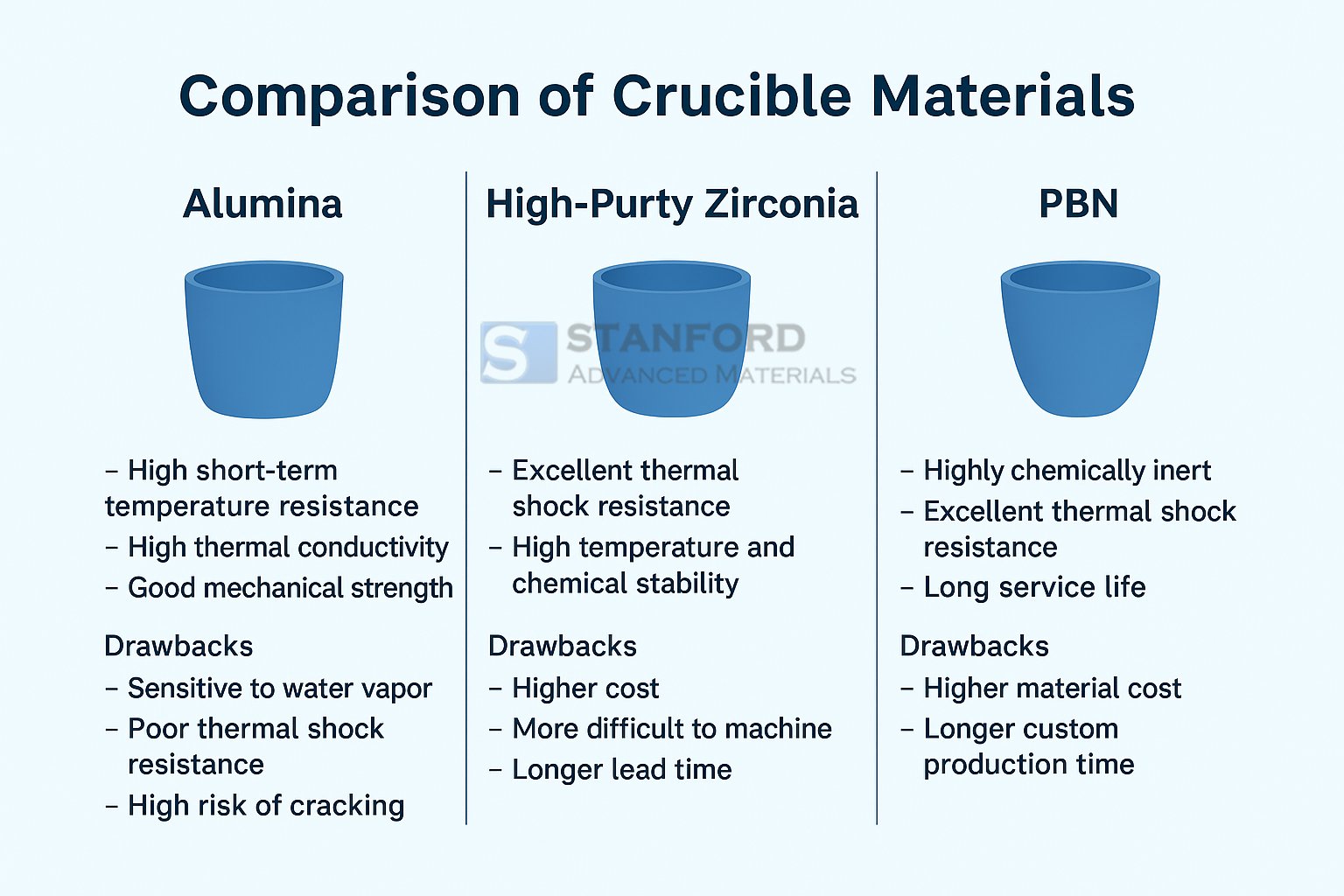

| Material | Strengths | Limitations |

|---|---|---|

| Alumina (Al₂O₃) | - Can withstand temperatures up to 1 800 °C - Good mechanical strength - Resistant to chemical corrosion |

- Susceptible to thermal shock - Sensitive to exposure to steam - Brittle, prone to cracking under extreme temperatures |

| Zirconia (ZrO₂) | - Improved resistance to thermal shock - Extremely high melting point (~2 700 °C) - Inert to chemicals in steam |

- Higher cost - More challenging to machine - Longer lead time for custom manufacturing |

| Pyrolytic Boron Nitride (PBN) | - Low thermal cycling endurance - Inactive in steam or harsh atmospheres - Stable under high-temperature conditions |

- Expensive - Requires custom fabrication for large volumes |

Recommendation and Implementation

After evaluating material performance, cost, and lead time, SAM provided several alternatives. The customer selected Pyrolytic Boron Nitride (PBN). PBN does not absorb water like alumina, and its layered microstructure responds well to thermal stress. Although the initial cost per crucible was higher, the customer prioritised long-term reliability and process continuity over short-term financial considerations.

Lisa Ross, senior engineer at SAM, remarked:

“Our objective was not merely to recommend a stronger material, but to align the crucible with the specific stress conditions. PBN was a suitable choice—its effectiveness thrives in heat, humidity, and repeated cycles.”

Customer Feedback

Following several weeks of use, the customer reported:

- No cracking or deformation after repeated thermal cycles

- Increased confidence in conducting high-temperature dehydration steps

- Fewer process interruptions and improved consistency across batches

“We were not aware of how significantly the atmosphere could affect the crucibles. SAM not only identified the issue, but they guided us through various material options until we found the right solution. The improvement was immediate.”

Conclusion

Material selection is not solely a question of temperature ratings—it involves selecting the entire context: atmosphere, cycle frequency, chemical exposure, and mechanical stress.

In this case, standard high-temperature ceramic—alumina—performed poorly under steam exposure and thermal shock. By switching to a more suitable material, the customer removed failure points, reduced downtime, and enhanced process stability.

Stanford Advanced Materials provided more than just a material—we assisted the customer in reassessing how their crucibles interact with the process environment. This distinction lies in supplying solutions rather than merely providing products.

Ready to collaborate with us? Send an Inquiry today.

Also, see our crucible category here.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento