How Lithium Niobate Is Utilised for Refractive Index Measurement

Owing to its exceptional electro-optic, piezoelectric, and nonlinear optical properties, lithium niobate possesses a vital application from wide-ranging telecommunications to research in photonics. Its most basic application among many is refractive index measurement—both as the target measurement object itself and as a tool for precision optical index measurement of other substances.

1. What Is Refractive Index

Refractive index, usually symbolised as n, is a measure of the amount of light that bends, or refracts, when travelling through a substance. It is a fundamental optical parameter defining the focusing of light by lenses, transmission in optical fibre of an impulse, and action of crystals in interaction with electromagnetic waves. Refractive index measurements need to be accurate in order to design lasers, modulators, sensors, and waveguides.

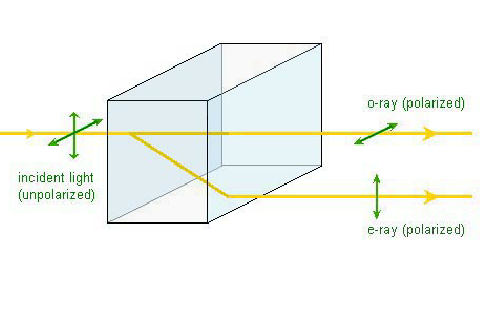

The optical properties of lithium niobate are anisotropic—it is a uniaxial crystal, meaning it has only one optical axis. Therefore, it is birefringent, having two different refractive indices:

• Ordinary refractive index (nₒ) – for light polarised perpendicular to the optical axis.

• Extraordinary refractive index (nₑ) – for light polarised parallel to the optical axis.

Birefringence is not merely a property—it is a useful tool for the analysis and manipulation of light.

[1]

2. Lithium Niobate's Optical Properties

Typical refractive indices of congruent lithium niobate at 633 nm and room temperature are:

•nₒ ≈ 2.286

•nₑ ≈ 2.203

They depend on wavelength, temperature, and composition (stoichiometric or congruent LiNbO₃). Researchers have derived Sellmeier equations to describe this wavelength dependence. A representative equation for the ordinary ray is:

nₒ^2(λ) = 5.35583 + 0.100473/ (λ^2 - 0.20692^2) + 100/(λ^2 - 11.34927^2)

where λ is wavelength in micrometres.

This optically highly specified response makes lithium niobate a calibrant material for refractive index measuring instruments and a subject of investigation in temperature- or wavelength-dependent refractometry.

3. Techniques Utilizing Lithium Niobate to Refractive Index Measurement

(a) Prism Coupling (m-line) Technique

Prism coupling is one of the most common methods, where a laser beam is transmitted through an index prism near in touch with a lithium niobate sample or thin film. Based on the angle of incidence, researchers observe clear "m-lines" that are related to guided optical modes. Based on mode angles, the effective refractive index of the film or substrate can be determined precisely.

Lithium niobate prisms are particularly favoured in this technique due to their:

•Low scattering loss and optical quality,

•Overall refractive index stability across an extremely broad wavelength regime, and

•Compatibility with both infrared and visible sources of light.

The technique can be configured to provide refractive index accuracy of greater than 10⁻⁴ and is therefore a highly sought tool in waveguide characterisation.

(b) Ellipsometry

In thin-film optics, ellipsometry is employed to detect polarisation changes of reflected light from a surface. In lithium niobate film growth on substrate materials such as sapphire or silicon, ellipsometric measurements are applied to quantify the film thickness and the dispersion of the refractive index.

Lithium niobate is anisotropic, and therefore VASE is typically employed. This facilitates full tensor characterisation—measurement of the wavelength dependence of the ordinary and the extraordinary indices.

(c) Interferometry

Michelson or Mach–Zehnder interferometer arrangements can be used for the detection of very minor refractive index variations. Lithium niobate, due to its large electro-optic effect (electric field-dependent refractive index), is an ideal material to test such a setup.

By applying controlled voltage to a lithium niobate crystal, researchers can view phase shifts of the interference fringes, from which they derive a change in refractive index (Δn). This property is also applied for interferometer calibration with the aim to measure refractive index variation in gases, liquids, and other solids with accuracy.

(d) Temperature-Dependent Refractometry

Since lithium niobate has a temperature-dependent refractive index, lithium niobate also has uses in thermally determining thermo-optic coefficients. It is common to step-heat the crystal with known values and angular displacement in transmitted or reflected beams.

For example, studies have shown thermo-optic coefficients (dn/dT) for LiNbO₃ are approximately:

•dnₒ/dT ≈ 3.9 × 10⁻⁵ K⁻¹

•dnₑ/dT ≈ 3.2 × 10⁻⁵ K⁻¹

This information is of great utility in the design of temperature-insensitive optical devices like frequency doublers and modulators.

4. Case Example: Refractive Index Calibration in Optical Waveguide Fabrication

Lithium niobate serves as both substrate material and the refractive index reference for integrated optical circuit manufacturing. Titanium is diffused into the surface of the crystal to raise the local refractive index by ~0.003 to 0.010 in the case of waveguide manufacturing in Ti:LiNbO₃.

To verify such a modification, engineers calculate mode propagation angles based on the prism-coupling technique outlined above. The reliable knowledge of the baseline refractive indices of lithium niobate simplifies the computation of diffusion depth and optical mode confinement accurately.

This ensures that resulting devices—Mach–Zehnder modulators, optical switches, and phase shifters—operate effectively in telecommunications networks.

Further reading: Lithium Tantalate vs. Lithium Niobate Wafers: A Comprehensive Comparison for Tech Enthusiasts

5. Why Lithium Niobate Dominates Optical Metrology

The usefulness of lithium niobate for refractive index measurement relies on the combination of:

•High optical transparency (350 nm to 5 μm)

•Reproducible, stable refractive indices

•Surface polishability at high levels

•Possessing a high electro-optic response that allows active tuning and modulation

These characteristics make it both an active material platform for future optical metrology devices as well as a passive measurement subject material.

6. Conclusion

From its initial employment as a refractive index calibration compound to dynamic electro-optic measurement, lithium niobate has been and remains an indispensable tool for optical science. Its birefringence, temperature stability, and well-established fabrication processes allow scientists and engineers to investigate the very roots of light–matter interaction. For more advanced optical materials, please check Stanford Advanced Materials (SAM).

Reference:

[1] Andrienko, Denis. (2018). Introduction to liquid crystals. Journal of Molecular Liquids. 267. 10.1016/j.molliq.2018.01.175.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento