How to Apply TiO₂ Powders to Develop Lithium Adsorption Prototypes

1. What Are Titanium Oxide Powders

Titanium dioxide (TiO₂), lithium titanate (Li₂TiO₃), and hydrogen titanate (H₂TiO₃), play an important role in material science. These compounds possess distinctive surface chemistry, crystal structure, and ion-exchange characteristics that make them candidates for environmental, energy, and catalytic applications.

[1]

In composition, these materials are layered titanates or perovskite-like materials where titanium ions are octahedrally coordinated by oxygen. The structure possesses vast interstitial space capable of accommodating lithium ions. Reversible insertion and extrusion of lithium without severe collapse in structure make these materials stable under repeated usage, an important property in battery use as well as lithium recovery operations.

Beyond their ion exchange potential, titanium oxide powders are environmentally friendly, thermally stable, and chemically inert—qualities that make them a choice for the development of new lithium adsorption prototypes.

2. What Are Lithium Adsorption Prototypes

Lithium adsorption prototypes refer to emerging material platforms or devices that have the capability to selectively absorb lithium ions (Li⁺) from various sources such as brines, seawater, or industrial wastewater. These prototypes represent an essential step in the research and development of sustainable lithium extraction technologies—a field of increasing importance with the fast-growing global demand for lithium-ion batteries.

Traditionally, lithium has been obtained through evaporation ponds or mineral processing, both of which are energy- and environmentally costly. Adsorption recovery is a cleaner process. It uses selective adsorbents—agents capable of attracting lithium ions but rejecting other competing ions such as sodium, potassium, or magnesium.

"Typical" examples of lithium adsorption include:

1. Adsorbent material: typically a lithium-ion filter made from titanates (e.g., H₂TiO₃ or Li₂TiO₃).

2. Contact system: to enable efficient ion exchange between lithium solution and adsorbent.

3. Recovery or desorption mechanism: for regeneration of adsorbent and recovery of purified lithium.

Laboratory testing in controlled conditions, material synthesis, and modification (e.g., protonation or calcination) to determine performance parameters such as selectivity, capacity, stability, and regeneration efficiency are included in the development process.

3. How to Use Titanium Oxide Powders to Develop Lithium Adsorption Prototypes

Titanium oxide powders such as Li₂TiO₃ (Lithium Titanate) and H₂TiO₃ (Hydrogen Titanate) form the nucleus of lithium adsorption material due to their selective ion-sieving properties. A generic research and development protocol to create a working prototype utilising such powders is outlined below.

Step 1: Material Preparation

For lithium adsorption, Li₂TiO₃ is typically synthesised or received as a finely divided, controlled particle size, high-purity powder. The powder can then be acid-leached to partially substitute lithium ions with hydrogen, producing H₂TiO₃. Such a change increases the material's lithium adsorbing ability by inducing vacancies in the crystal lattice, which can be filled by lithium ions from solution.

Typical reaction:

Li₂TiO₃ + 2H⁺ → H₂TiO₃ + 2Li⁺

Either form—H₂TiO₃ or Li₂TiO₃—may be employed based on whether the study is on adsorption (H₂TiO₃) or lithium intercalation/deintercalation (Li₂TiO₃).

Step 2: Structural and Surface Characterisation

Prior to prototype fabrication, it is necessary to examine the powder structure and morphology through XRD (X-ray diffraction), SEM (scanning electron microscopy), and BET (surface area measurement). These procedures ensure that the titanate structure is stable and that surface area and porosity are adequate for efficient ion exchange.

Surface hydroxyl groups and oxygen vacancies often enhance lithium adsorption capacity, and hence researchers can fine-tune these properties by modifying synthesis conditions (e.g., calcination temperature or acid concentration).

Step 3: Prototype Fabrication

The prepared titanium oxide powder can be used in a range of prototype configurations:

•Powder-filled packed columns for continuous lithium extraction.

•Membrane composites, with titanate particles dispersed into polymer matrices to combine mechanical strength with ion selectivity.

• Pelletised or granulated adsorbents, designed for ease of handling and re-use.

The main goals at this stage are good solid-to-fluid contact, good structural stability, and low powder loss when in use.

Step 4: Lithium Adsorption and Desorption Testing

Prototype testing consists of placing the adsorbent in lithium-bearing solutions (e.g., simulated brines) and tracking lithium uptake over time.

Key parameters are:

• Adsorption capacity (mg Li⁺/g adsorbent)

• Selectivity (Li⁺ vs. Na⁺, K⁺, Mg²⁺)

• Cycle stability (adsorption-desorption repeatability)

After adsorption, the desorption step—usually achieved using the help of diluted acids (such as HCl)—releases lithium ions back into solution to recover them. This also re-establishes the H₂TiO₃ phase to be recycled several times.

Step 5: Performance Evaluation and Optimisation

Scientists evaluate prototype performance based on efficiency, selectivity, and structural durability. The pH, temperature, and solution ionic strength are optimised to maximise lithium recovery yields. Other optimisations such as surface doping or composite development with carbon compounds can improve adsorption kinetics and mechanical toughness.

4. SAM's Case Study

A recent inquiry received by Stanford Advanced Materials (SAM) illustrates the growing research interest in this topic.

Case Summary:

•Product: LM1301 Lithium Titanate Powder (Li₂TiO₃) (CAS No. 12031-82-2)

•Customer: A French Engineering Company

•Application: Production of lithium adsorption prototypes

The researcher sought titanium oxide powders specifically Li₂TiO₃ or H₂TiO₃ to examine if they can be used in lithium adsorption. Li₂TiO₃ is well suited for this application because of its stable spinel-like structure, high ion-exchange reversibility, and environmental benignity.

SAM's LM1301 Lithium Titanate Powder offers:

•High purity and controlled particle morphology

•Excellent phase stability during ion exchange cycles

•Chemical composition regular enough to facilitate prototype development at laboratory scale

SAM allows energy companies and research institutions to move towards cleaner lithium recovery methods by providing advanced materials like LM1301. These prototypes are not only efficient at extracting more lithium from unconventional sources but are also cleaner than conventional mining.

Conclusion

Titanium compound powders, specifically Li₂TiO₃ and H₂TiO₃, are enabling advancements in lithium adsorption technology. Their chemical stability, selectivity, and stable structures make them materials with potential for sustainable recovery and purification of lithium. Through systematic synthesis, characterisation, and prototype testing, researchers can utilise these materials to respond to the growing demand for clean energy storage technology.

Reference:

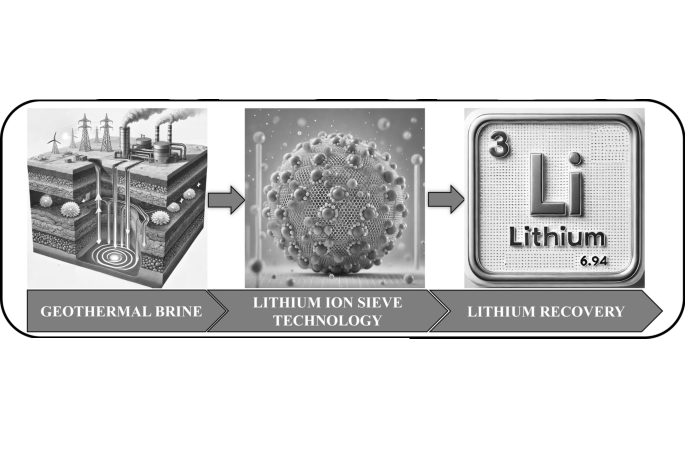

[1] Sujoto, V.S.H., Prasetya, A., Petrus, H.T.B.M. et al. Advancing Lithium Extraction: A Comprehensive Review of Titanium-Based Lithium-Ion Sieve Utilisation in Geothermal Brine. J. Sustain. Metall. 10, 1959–1982 (2024). https://doi.org/10.1007/s40831-024-00933-z

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento