Different Types of Silicon Wafers

Many individuals may have worked with silicon wafers without realising it. Anyone who has ever used a computer or a mobile phone has likely relied on silicon wafers before. As one of the principal suppliers of silicon wafers in the market, Stanford Advanced Materials (SAM) receives queries such as "What is a silicon wafer?" or "Which silicon wafer should I acquire for this purpose?" This comprehensive guide to silicon wafers provides answers to these questions.

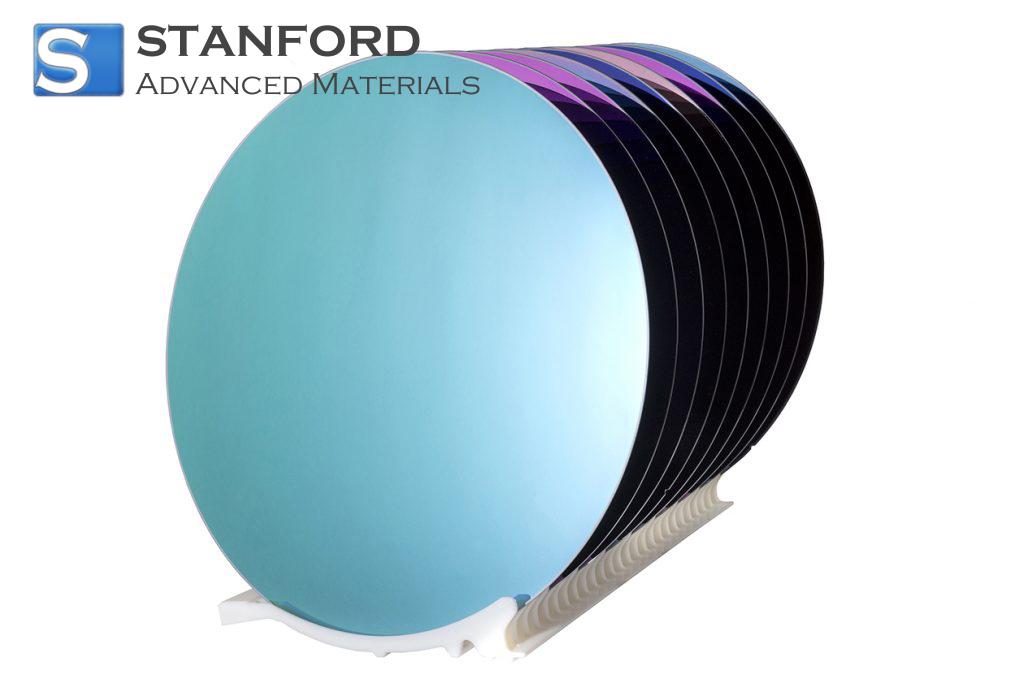

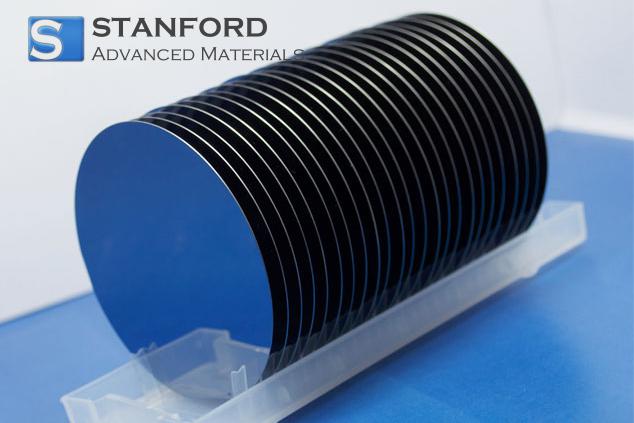

SAM offers a variety of customised silicon wafers including prime wafers, test wafers, and reclaimed wafers. Based on different parameters such as Orientation Crystals, Resistivity, Thickness, and Diameter, they ensure that consumers obtain a suitable wafer for their requirements.

![]()

Silicon Wafers by Crystal Structure

The silicon wafer crystal structure has been found to influence its electrical, mechanical, and thermal properties.

- Monocrystalline Silicon Wafers: These wafers are made from a single crystal and guarantee consistent electrical properties with fewer defects. While Czochralski wafers cater to IC applications and high-efficiency solar cells, FZ wafers with extremely low impurities are used in high-power electronics, RF components, and high-voltage devices.

- Polycrystalline Silicon Wafers: These are produced from multiple crystal formations to reduce costs, although they are not as uniform as single crystal wafers. These wafers are utilised in solar panels and other economical semiconductor devices.

- Amorphous Silicon Wafers: Utilised for manufacturing thin films such as TFT display screens, image sensors, and thin film solar cells.

Silicon Wafers by Orientation

Crystalline orientation is critical for wafer processing and etching. SAM provides wafers with the most prevalent orientations:

- ⟨100⟩ Wafers - Suitable for oxidation and etching, ideal for CMOS logic, DRAM, and general IC processing.

- ⟨110⟩ Wafers – Chosen for MEMS and anisotropic etch applications.

- ⟨111⟩ Wafers - Favoured for MEMS, sensors, and power devices where enhanced mechanical strength is necessary.

![]()

[1]

Silicon Wafers Based on Doping Types

"Doping" modifies the electrical properties of a semiconductor wafer through the following:

- P-Type Wafers - Boron-doped wafers primarily used in solar cells and CMOS technology.

- N-Type Wafers - Phosphorus or arsenic doped, utilise electrons as charge carriers, thus are more mobile and resistant to ionising radiation.

- Resistivity Variations - SAM can supply wafers from lightly doped to heavily doped according to device specifications, such as high resistivity wafers that can be used for RF technology or low resistivity wafers suitable for power electronics.

Surfaced Finish & Special Engineering

The characteristics and engineering of the wafer's surface make it suitable for sophisticated applications.

- Highly polished wafers - Single-sided or double-sided polished wafers for ICs, MEMS, or photonics.

- Lapped or Etched Wafers - Moderate surface finish, often utilised for R&D applications and power devices.

- SOI (Silicon on Insulator) Wafers - Parasitic capacitance reduced for RF, LP, and automotive applications.

- Ultra Thin Wafers - Thickness less than 100µm; primarily for Flexible Electronics and the packaging of 3D integration.

Related reading: Comparing SOI vs. Silicon Wafers: What's Best for Your Semiconductor Project?

Summary Table: Different Kinds of Silicon Wafers

|

Silicon Wafer Type |

Crystal Structure / Orientation |

Doping / Resistivity |

Surface Finish |

Typical Applications |

|

Monocrystalline (CZ) |

Single crystal, ⟨100⟩ or ⟨111⟩ |

P-type or N-type, standard resistivity |

Polished (SSP/DSP) |

ICs, CMOS logic, high-efficiency solar cells |

|

Monocrystalline (FZ) |

Single crystal, ⟨100⟩ |

Ultra-low impurities, high resistivity |

Polished |

High-power electronics, RF devices, high-voltage ICs |

|

Polycrystalline |

Multi-grain |

P-type or N-type, moderate resistivity |

Lapped or polished |

Photovoltaics, cost-sensitive semiconductors |

|

Amorphous Silicon (a-Si) |

Non-crystalline |

Lightly doped |

Thin-film surface |

TFT displays, thin-film solar cells, image sensors |

|

SOI (Silicon-on-Insulator) |

Monocrystalline layer on insulating layer |

P-type or N-type, variable resistivity |

Polished |

RF ICs, low-power devices, automotive electronics |

|

Ultra-Thin Wafers |

Single or polycrystalline |

P-type or N-type, custom resistivity |

Polished |

Flexible electronics, advanced packaging, 3D integration |

This table provides a summary of various essential characteristics of different silicon wafers, allowing you to determine which product you require. SAM's reputation as a reliable silicon wafer supplier ensures that all silicon wafers are of the highest quality.

Conclusion

Silicon wafers are fundamental to modern electronics, whether they are in common devices, computers, micro-electromechanical systems, or solar cells. The variety of orientations, doping types, surface finishes, and engineering features significantly contribute to informed decision-making.

By procuring high-quality silicon wafers from a reputable silicon wafer supplier such as SAM, manufacturers and researchers can acquire silicon wafers that meet specific requirements, thereby enabling optimal innovation within the semiconductor industry.

Reference:

[1] Mohd Said, Nur Azura & Ogurtsov, Vladimir & Herzog, Grégoire. (2014). ELECTROCHEMICAL BIOSENSOR BASED ON MICROFABRICATED ELECTRODE ARRAYS FOR LIFE SCIENCES APPLICATIONS. 10.13140/RG.2.2.11066.49603.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews