5 Iridium Applications in Electronics

Iridium is among the most scarce and expensive elements in the platinum family. It is known for incredible resistance to corrosion, high melting point, and catalytic properties. Such properties are responsible for the significant use of iridium in various high technology applications, especially in the electronic and electrochemical sectors.

1. Electrodes & Electrical Contacts

It is widely employed as the material for the production of efficient electrodes and electrical contacts for use in semiconductors and electronics. These are needed for the construction of devices that require stable performance, such as high-performance spark plugs for the automotive industry, aerospace relays, and satellite systems. Its high melting point (~2,466°C) makes it the most suitable material for use in devices and systems that require reliable performance and long life as well as for the production of spark plugs for the automotive and aviation industry.

The iridium products in this market include iridium-point spark plugs for automobiles and small engines, which offer increased lifespan and improved ability to achieve efficient ignition. High reliability electrical contacting solutions for the aerospace/satellite market utilise iridium, ensuring stable electrical connections for an extended period of time despite harsh environmental conditions.

Related reading: 5 Common Uses of Iridium

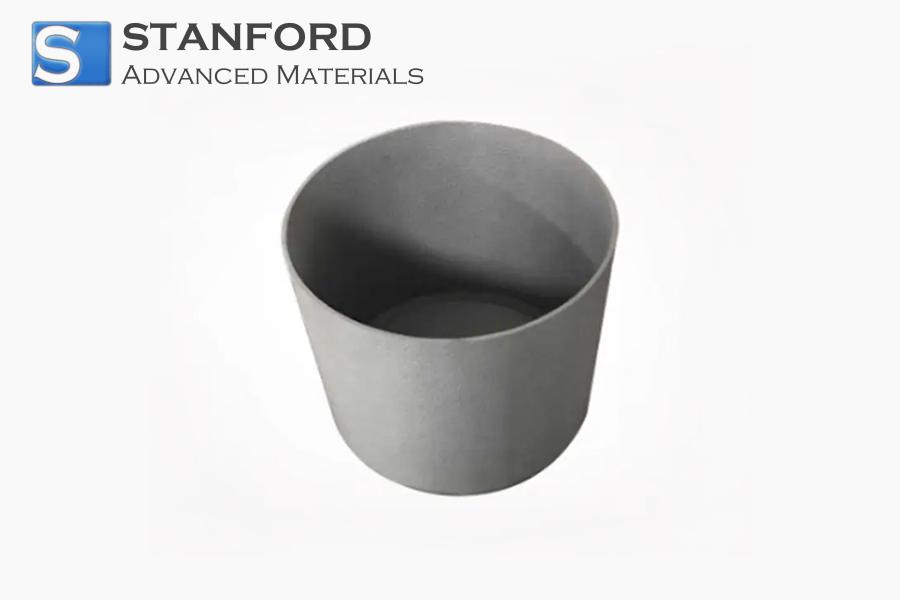

2. Crucibles for Semiconductor Crystal Growth

The ability of iridium to resist high temperatures and corrosive environments makes it highly desirable for high-temperature applications, specifically in the semiconductor industry. The primary application of iridium is in the Czochralski process, where it is employed as the ultra-pure material for the preparation of high-quality single crystals such as sapphire or YAG. These crystals have various applications, including light-emitting diode substrates, optical windows, or laser components. The ability of iridium to resist temperatures above 2,000°C without contamination is crucial for the preparation of ultra-pure materials.

3. Thin Film for Electronics

Iridium thin films have various applications in the electronics segment, specifically in applications related to Magnetoresistive Random Access Memory (MRAM) and Spin-Orbit Torque (SOT) devices. The spin-orbit coupling properties of iridium are utilised in emerging Spintronics devices that require high electrical conductivity and magnetic properties. Iridium has applications in non-volatile memory preparation, addressing instability and high power consumption in digital memory applications.

Examples of iridium products include iridium manganese thin films that are used to manufacture MRAM, which require a magnetic reference. Another example of products made of iridium in this category includes sputtering targets used to create thin films or films of iridium oxide.

4. Specialized Sensors & Detectors

It is applied in the manufacture of sensors and detectors employed in high-energy fields such as radiation and thermal detectors. Its high density and inertness make it suitable for the production of Radioisotope Thermoelectric Generators that power satellites to produce electricity. It is applied in high-temperature thermocouples produced from an alloy of iridium-rhodium (Ir/Rh40) that can measure high temperatures of up to 2,000°C. These are used in aerospace industries to measure high temperatures.

Iridium thermocouples are applied in this field due to their applications in high temperature measurement. Iridium sensors are also used to detect radiation as they enable monitoring of the emission of particles.

5. OLED & Niche Applications

Apart from the common applications of iridium, the element is also used in developing technologies. Some applications include iridium in the production of organic light-emitting diodes. In the production of OLED, iridium(III) compounds, for example, Ir(ppy)₃, act as the phosphorescent emission layer. The compounds used in the production of OLEDs allow for displays with an internal quantum efficiency of nearly 100%.

Additional applications of iridium include its utilisation in the preparation of devices based on field emission used to demonstrate advanced display and vacuum microelectronics technology. Due to its low work function, iridium is considered a potential material for cold cathodes.

Challenges & Considerations

Despite the significance of the element in electronics, several challenges arise in its use. For example, the rarity of the element significantly contributes to the challenges posed. Additionally, the value of the element is considerably high because the current production level stands at 7-10 tonnes annually. The cost of this element has varied between £4,000 and £6,000 per troy ounce.

Moreover, the brittleness of iridium at ordinary temperatures poses challenges in the fabrication of the element. Furthermore, the availability of iridium is limited to a few regions, primarily South Africa, where it is typically a by-product of platinum mining. This restricts its availability, as the supply largely depends on the locations where it is mined.

Summary Table: Iridium Applications in Electronics

|

Product Form |

Related Application |

Key Property Utilised |

|

Fine Wire/Tip |

High-performance spark plug electrodes |

Melting point, wear resistance |

|

Crucible |

Sapphire & specialty crystal growth |

High-temp strength, purity |

|

Sputtering Target |

MRAM, SOT-MRAM thin films |

Antiferromagnetism, spin-orbit coupling |

|

Complex (Organic) |

Phosphorescent OLED emitters |

Efficient phosphorescence, colour tunability |

|

Thin Film Coating |

Diffusion barriers, thermoelectrics |

Stability, electrical conductivity |

In conclusion, iridium remains an indispensable material in modern electronics and electrochemical applications. While its rarity and cost present challenges, the metal's performance characteristics make it an irreplaceable material in applications ranging from green hydrogen production to high-efficiency lighting. As technology continues to evolve, iridium will remain a critical enabler of innovation in the electronics industry.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews