How Temperature-Controlled Ovens Enable Quasi-Phase Matching in PPLN

Periodically Poled Lithium Niobate (PPLN) crystals are one of the cornerstones of today’s nonlinear optics. The ability of these crystals to perform efficient wavelength conversion of light has unlocked the fields of laser advancements, telecom, quantum optics, and spectroscopy. Behind their functioning is a delicate process known as quasi-phase matching (QPM). Maintaining this regime and realising it entails delicate control of the temperature, most commonly attained by employing temperature-controlled ovens.

Understanding Quasi-Phase Matching in PPLN

PPLN and other nonlinear crystals are used in processes such as second-harmonic generation (SHG), optical parametric oscillation (OPO), and difference frequency generation (DFG). In all these processes, two or more photons interact within the crystal to generate light at a different wavelength. For effective conversion, interacting light waves must remain in phase as they propagate through the crystal.

In actuality, perfect phase matching never occurs naturally due to dispersion, where different wavelengths travel at different speeds in the crystal. Discrepancy leads to destructive interference and reduces conversion efficiency.

In order to solve this, researchers developed quasi-phase matching. Instead of relying on natural birefringence, they periodically reverse lithium niobate's ferroelectric domains. The reversal, typically through electric-field poling, re-syncs the phase mismatch on a regular basis. The result is constructive accumulation of the desired optical signal.

However, the exact conditions for QPM rely on the refractive indices of the crystal, which are highly temperature-sensitive. It is here that thermal control proves necessary.

Why Temperature Control Matters in PPLN

The refractive index of lithium niobate changes with temperature. Even slight variations—tens of degrees—can affect the phase-matching condition. For processes that require stable and efficient frequency conversion, such as generating green light from infrared lasers or generating entangled photon pairs for quantum communication, spontaneous temperature change can be detrimental.

For example:

•A 1 °C temperature shift in SHG experiments can move the phase-matching wavelength a few hundredths of a nanometre.

•Thermal drift in OPOs can cause mode hopping, unstable output power, or even lead to no oscillation at all.

•Terahertz generation efficiency relies highly on having well-defined thermal conditions.

PPLN crystals must thus be placed within a temperature-controlled oven, with crystal conditions stabilised to fractions of a degree.

How PPLN Temperature-Controlled Ovens Work

A PPLN temperature-controlled oven is not your average laboratory heating device. It is a finely crafted machine that is designed to provide:

1.Uniform Heating – The oven assures that every region of the crystal experiences the same temperature. Inconsistent heating can distort the domain structure and generate different performances.

2.High Accuracy Stability – High-performance ovens are capable of maintaining temperatures with precision enhanced beyond ±0.1 °C. This precision keeps the quasi-phase-matching condition firmly in place for extended experiments.

3.Broad Tuning Range – Temperature is tunable to adjust the effective refractive index of the PPLN crystal. It allows phase matching over a range of input wavelengths or targeted output frequencies.

4.Minimum Thermal Drift – Insulated designs, commonly using PID (proportional-integral-derivative) control loops, minimise the influence of external variation, e.g., room temperature changes or laser heating.

5.Small Form Factor – Micro-ovens in integrated or chip-scale designs are utilised. The miniature-sized heating platforms offer waveguide-based PPLN device temperature stabilisation with compactness for convenient utilisation in portable setups.

Applications Enabled by Thermal Control in PPLN

Because quasi-phase matching is sensitive to temperature, temperature-controlled ovens hold the key to many applications:

•Laser Frequency Doubling (SHG): Interconversion of near-infrared lasers to green light, for example, Nd:YAG 1064 nm to 532 nm conversion.

•Optical Parametric Oscillators (OPOs): Generation of widely tunable coherent light sources in the visible and infrared spectra.

•Quantum Optics: Generation of entangled pairs of photons for quantum key distribution and computation.

•Terahertz Wave Generation: Enabling THz spectroscopy and imaging through difference frequency generation in PPLN.

•Telecommunications: Enabling wavelength conversion and signal processing for fibre optic communications.

In all of these applications, uniform temperature control ensures not just efficiency but also reproducibility and the long lifespan of the device.

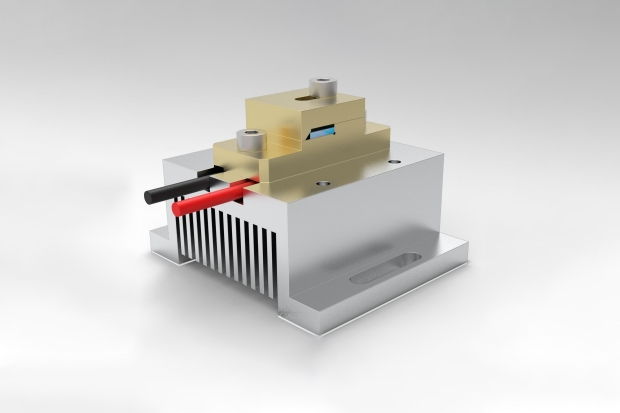

SAM's PPLN Temperature-Controlled Oven

Stanford Advanced Materials (SAM) supplies a temperature control system specially made for PPLN crystals. The system includes the oven body and external controller, working together to maintain crystal temperature stability for phase matching assurance.

The oven chamber can accommodate PPLN samples as large as 50 mm × 10 mm × 2 mm (L × W × H), and thus it can be utilised for both lab research and real photonic systems. With its wide temperature tuning range, users are able to easily alter and adjust conditions, and tuning is simple and rapid.

These capabilities render SAM's PPLN temperature-controlled oven a universal and reliable research and industrial instrument.

Conclusion

Temperature-controlled ovens are not accessories in nonlinear optics; they are quasi-phase matching enablers in PPLN crystals. They stabilise and control the thermal environment to enable control over refractive indices and, extremely importantly, maintain the sensitive balance needed for efficient frequency conversion.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento