The Overview Of Nanomaterials

A brief history of nanotechnology development

In 1959, Nobel laureate Richard Feynman predicted that humans could use small machines to build even smaller ones. He further stated that atoms might eventually be arranged individually to produce items as required. This prediction represents one of the earliest foundations of nanotechnology.

In 1991, scientists in the United States synthesised carbon nanotubes. They measured that these tubes possessed one-sixth the mass per equivalent volume of steel and had a strength ten times greater. They were designated as a superfibre. The discovery of nanomaterials advanced the quantification of material properties. In 1999, annual revenue from nanoproducts reached 50 000 000 000 US dollars.

What is a nanomaterial?

A nanometre (nm) is a unit of length equal to 10⁻⁹ metres. For bulk matter, this is extremely small. A human hair typically has a diameter of 7 000–8 000 nm. Human red blood cells usually measure between 3 000 and 5 000 nm, and viruses range from several tens to hundreds of nanometres. The grain size of metals typically lies in the micrometre range. Atoms and molecules were once described in angstroms. One angstrom approximates the diameter of a hydrogen atom, and 1 nm equals 10 angstroms.

It is generally accepted that nanomaterials should meet two criteria. Firstly, their characteristic size should range between 1 and 100 nm. Secondly, they must exhibit physical and chemical properties that differ from those of bulk materials.

Materials are classified as nanomaterials if at least one of their three dimensions is on the nanometre scale (0.1–100 nm) or if they are composed of such units. This generally corresponds to a cluster of 10 to 100 closely packed atoms. Currently, nanomaterials are applied in the following fields.

Natural nanomaterials

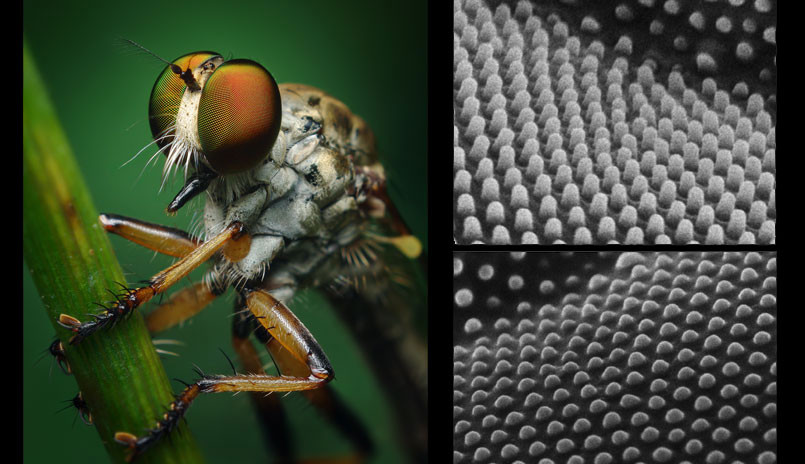

Sea turtles lay eggs along the coast of Florida, USA. After hatching, juveniles must swim to waters near the United Kingdom to feed and develop. Adult turtles later return to the Florida coast to lay eggs. This round-trip takes approximately five to six years. Their navigation over tens of thousands of kilometres is assisted by nanomagnetic materials in their brains. Biologists studying the orientation of pigeons, dolphins, butterflies and bees have also detected nanomaterials in these species.

Nano-scale magnetic materials

Most nanomaterials used in practice are synthesised. Their small size, single-domain structure and high coercive field enable magnetic recording materials composed of nanoparticles to offer improved tonal and image quality. They also deliver a recording density approximately 10 times greater than that provided by γ-Fe2O3. Superparamagnetic nanoparticles are used to produce magnetic fluids for electroacoustic devices, damping systems, rotary seals, lubrication and mineral processing.

Nano-ceramic materials

The grains of conventional ceramics are not easily repositioned. Such materials are brittle, and sintering temperatures are high. Nano-ceramics consist of fine grains that can move over adjacent grains. Consequently, these materials exhibit high strength, high toughness and good ductility. They can be processed at ambient or elevated temperatures without requiring high-temperature treatment.

Nanosensors

Nano-zirconia, nickel oxide, titanium dioxide and other ceramics exhibit high sensitivity to temperature fluctuations, infrared radiation and exhaust emissions. They are used in the manufacture of temperature sensors, infrared detectors and automotive exhaust detectors, thereby achieving higher detection sensitivity than conventional ceramic sensors.

Functional materials with nano-gradients

In hydrogen and oxygen thrusters for aerospace, the inner surface of the combustion chamber must withstand high temperatures while its outer surface contacts a coolant. Consequently, the inner surface is produced from ceramic and the outer surface from metal with good thermal conductivity. It is difficult to join discrete ceramics and metals. By gradually varying the composition during production, the metal and ceramic can be joined to form gradient functional materials. When metallic and ceramic nanoparticles are mixed and sintered, their gradual concentration change meets the requirement for high internal temperature resistance and efficient external heat conduction.

Nano-semiconductor materials

Semiconductor materials such as silicon and gallium arsenide possess several useful properties. The quantum tunnelling effect in nano-semiconductors causes abnormal electron transport, a reduction in conductivity and a decline in thermal conductivity as the particle size decreases. In some tests, a negative thermal conductivity value was observed. These properties are significant in the production of large-scale integrated circuits (LSI) and optoelectronic devices. Under illumination, nano-semiconductor particles generate electrons and holes with strong oxidation and reduction capacities. They oxidise toxic inorganic substances and decompose many organic compounds, resulting in non-toxic and odourless carbon dioxide, water and other by-products.

Nano-catalytic materials

Nanoparticles serve as effective catalysts. Their small size produces a high surface area relative to volume. Their chemical bonding and electronic states at the surface are distinct and feature incomplete atomic coordination. This increases the number of active sites. The hydrogenation of organic compounds with nickel or copper–zinc nanoparticles is efficient and can replace more expensive platinum or palladium catalysts. Using a nano-catalyst such as platinum black, the temperature required for ethylene oxidation is reduced from 600 ℃ to room temperature.

Medical applications

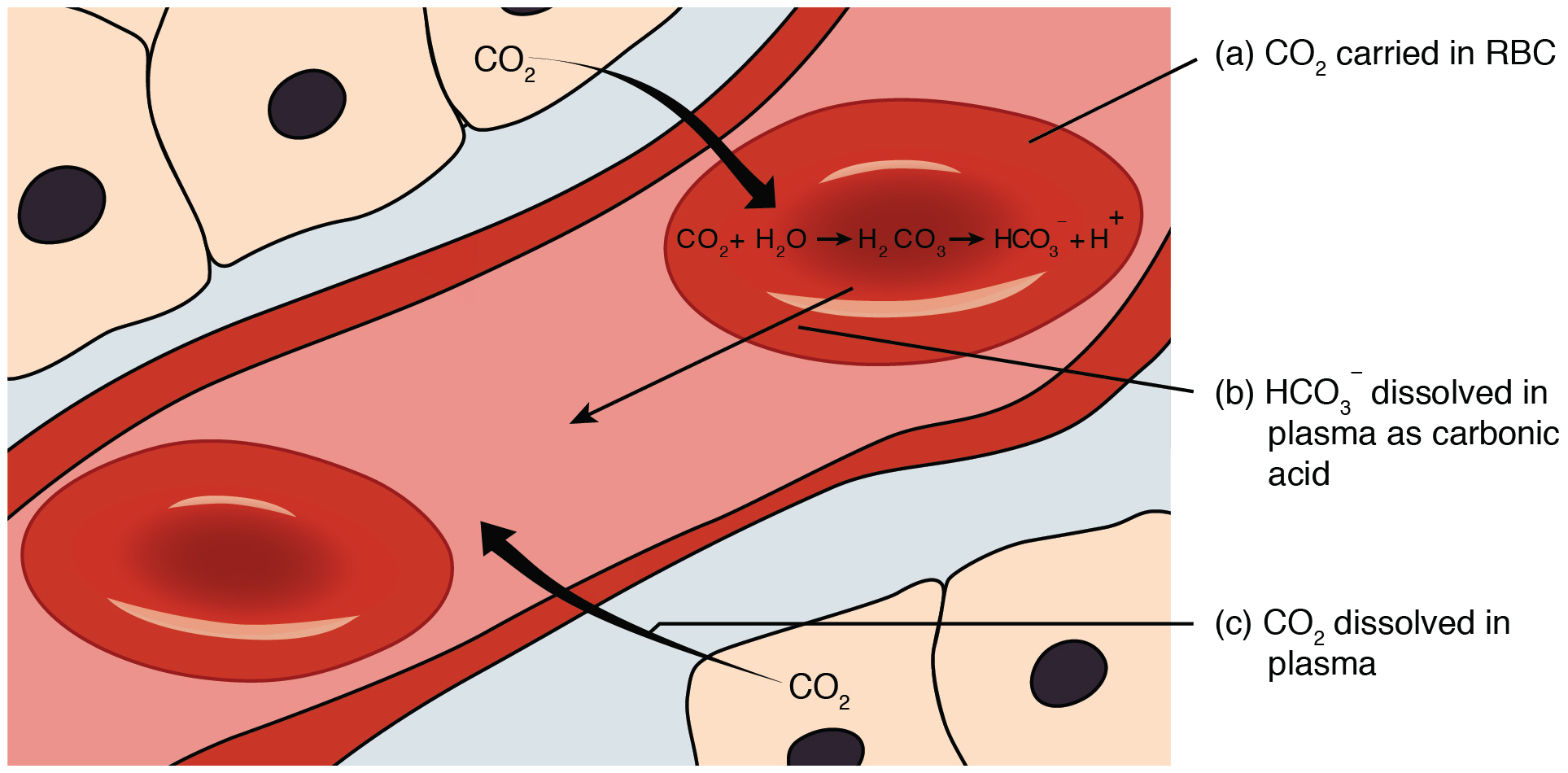

Human red blood cells measure between 6 000 and 9 000 nm; nanoparticles, by contrast, are only a few nanometres in size. They can move freely in the bloodstream. When various therapeutic nanoparticles are injected into different parts of the body, diagnostic and treatment procedures become more effective than conventional methods. Carbon materials are readily soluble in blood. In the 21st century, artificial heart valves were produced by depositing a layer of pyrolytic carbon or diamond-like carbon onto a substrate. This deposition process is complex and is generally suited for the manufacture of hard materials.

Interventionally delivered gas sacks and catheters are generally manufactured from highly elastic polyurethane. By incorporating carbon nanotubes, which have a high length-to-diameter ratio and are composed entirely of carbon, into the polyurethane, the polymer retains its mechanical properties and remains easy to process and form. This results in improved blood compatibility. Studies indicated that the nanocomposite is less likely to cause haemolysis and activate platelets. The application of nanotechnology has refined pharmaceutical production. Atoms and molecules are arranged on the nanometre scale to produce pharmaceuticals with specific functions. Nanoparticles facilitate the transport of drugs in the body. Multilayered formulations actively target cancer cells and repair damaged tissue. New diagnostic instruments that exploit nanotechnology detect diseases from small blood samples by analysing proteins and DNA. The surface of nanoparticles may be modified to create drug carriers with targeted, controllable release and straightforward detection. This provides a new method for treating local pathological conditions and offers a novel direction for drug development.

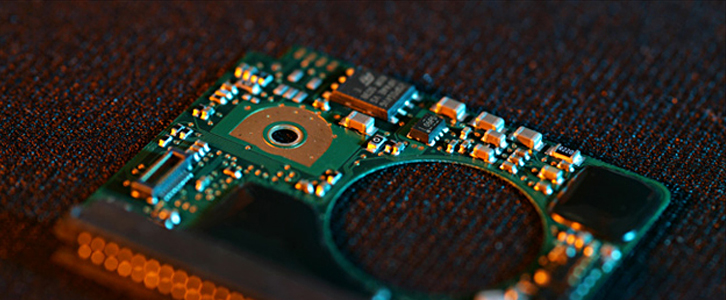

Nano-mechanical computer

The first electronic computer was developed in 1945 by American universities and the military. It used 18 000 vacuum tubes, weighed 30 t and occupied about 170 m². It executed approximately 5 000 operations per second.

After half a century, developments in integrated circuit technology, microelectronics, memory systems, computer languages and programming techniques advanced computing significantly. Today’s computers are compact enough to fit on a desk. They weigh approximately one ten-millionth of the weight of their predecessors and operate much faster.

If nanotechnology is employed in electronic computer production, future computers will be molecular in nature. They will be more compact than current models and will reduce material and energy usage.

Memory chips made from nanomaterials, which can interface with hard drive card readers and provide storage capacities 1 000 times greater than conventional chips, are already in production. The widespread use of nanomaterials may reduce the size of computers to that of a palm-top device.

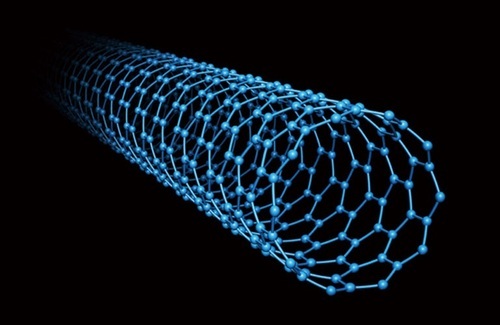

CNT (Carbon Nanotube)

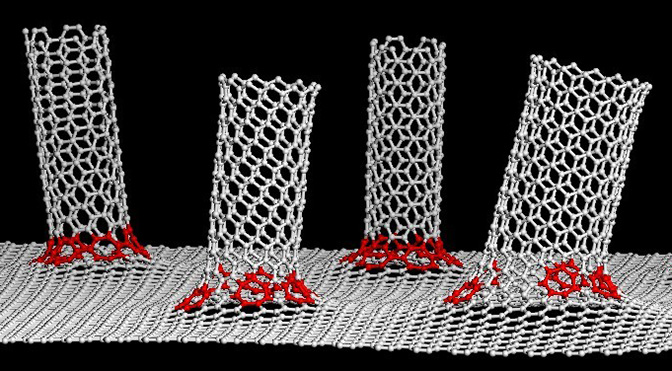

In 1991, Japanese experts produced a material known as carbon nanotubes. These are tubes composed of a series of hexagonally arranged carbon atoms, or of several coaxial tubes. The ends of both single- and multi-walled tubes are often sealed, as illustrated. The diameter and length of these tubes are at the nanometre scale, thereby justifying the term carbon nanotube. Their tensile strength is 100 times that of steel, and their electrical conductivity exceeds that of copper.

Heating carbon nanotubes in air to approximately 700 ℃ causes oxidation damage at the tube tips, resulting in open nanotubes. A low-melting metal (for example, lead) is then evaporated by an electron beam and condenses on the open nanotube. The metal moves into the hollow core of the nanotube. Due to the extremely small diameter, metal wires formed inside are very thin. These are known as nanowires. Consequently, carbon nanotubes used in conjunction with nanowires can be applied to produce new superconductors.

Nanotechnology remains in its early stages in many countries. In the United States, Japan and Germany, research is in progress. New theories and technologies are continuously being developed.

Household appliances

Multifunctional nanoplastic made from nanomaterials possesses antibacterial, deodorising, antiseptic, anti-ageing and UV-protective properties. It can be used as an antibacterial, deodorising plastic in the casings of refrigerators and air conditioners.

Environmental protection

Nanomembranes with specific functionalities in environmental science are under development. These membranes detect and filter chemical and biological contaminants, thereby eliminating pollution.

Textile industry

Nano-SiO2, nano-ZnO and nano-SiO2 composite powder materials are added to synthetic fibre resin. After the extrusion and weaving processes, undergarments and garments can be sterilised, protected against mould, deodorised and rendered resistant to ultraviolet radiation. They are also used in the manufacture of antibacterial undergarments and accessories that meet defence industry requirements for UV-resistant functional fibres.

Technical industry

Nano-powder coatings applied to the metal surfaces of critical mechanical components are used to improve wear resistance, hardness and service life.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento