Case Study: Application Of Tantalum Marker Band In Medical Devices

Marker bands are cut from precious metals and other specialised metals. The cut bands can be processed in various diameters according to clinical requirements. Marker bands are used in the medical industry for radiopaque marking of catheter tubes and sensors during angioplasty and other procedures. Platinum, gold and palladium marker bands are standard products for many medical device components where radiopacity is required. In this article we review the application of Tantal Marker Bands in medical devices.

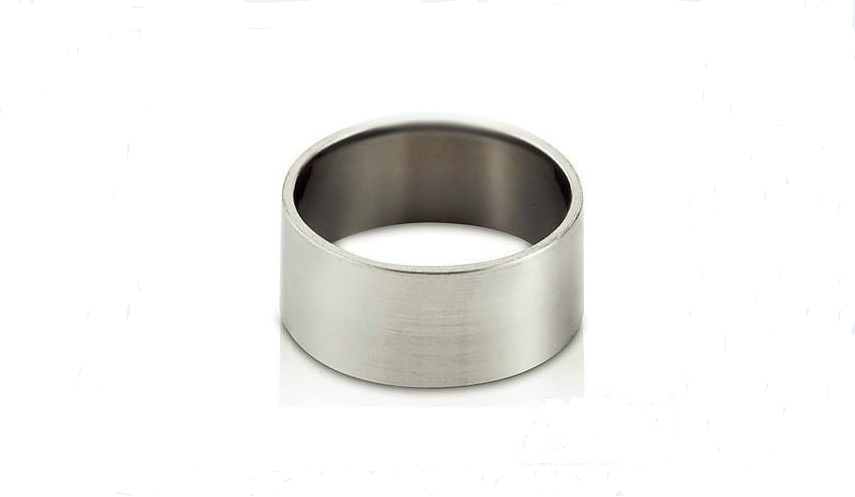

Tantal Marker Band

A customer of Stanford Advanced Materials (SAM) is a medical technology company that focuses on providing clinical medical technology solutions. The company previously employed conventional marker bands for radiopaque marking. These bands were produced from gold or platinum and affixed by forging or crimping. Although the processes have been refined over the years, there remains a risk that the conventional marker band may detach from the catheter tube. The costs are high because the rare metals incur substantial expense.

Industry professionals recognise that medical tantalum is a metal that exhibits biocompatibility and resistance to physiological corrosion. Tantalum may be implanted in bone to form a direct osseous connection with the adjacent new bone. Muscles and other soft tissues may attach to the tantalum rod and grow without causing stimulation or toxic side effects in the human body. Manufacturing tantalum into marker bands is challenging because its processing properties are less favourable than those of precious metals. The principal difficulty lies in the processing technology.

The company approached SAM given that we possess an established processing technology for tantalum marker bands. Our tantalum marker bands have inner diameters ranging from 0.356 mm (0.014 in) to 5.080 mm (0.200 in) and wall thicknesses from 0.051 mm (0.002 in) to 0.762 mm (0.030 in). These dimensions meet the defined medical requirements. The radiographic opacity of tantalum bands is essentially equivalent to that of precious metal bands, yet the cost is reduced by 50%. We manufacture our marker bands using the same grade of tantalum as is specified for the catheter shaft. This method enables secure assembly using hot bonding, thereby avoiding additional expensive manufacturing processes required for conventional radiopaque marker bands.

"I am satisfied to have found Stanford Advanced Materials in time. Their engineers promptly understood my operating conditions and recommended the correct materials for my medical application. Consequently, my staff now achieve increased throughput, reduced costs and improved efficiency," stated the company representative.

With decades of experience in advanced materials, SAM offers expertise in the processing of tantalum marker bands. Given our quality assurance system and strict standards, you may expect that the medical components provided meet the required specifications. Medical technology companies with similar applications should consult a SAM engineer or sales representative regarding their specifications for medical devices to obtain further information.

Conclusion

We thank you for reading our article and hope that you have found the information useful. If you wish to learn more about Tantal Marker Bands or other tantalum products, we recommend visiting Stanford Advanced Materials (SAM) for further details.

Stanford Advanced Materials (SAM) is a global supplier of tantalum products with over two decades of experience in the manufacturing and distribution of tantalum products. The company offers Tantal foils and tantalum marker bands that meet the research and production requirements of its customers. Consequently, SAM is positioned to serve as a supplier and business partner for tantalum marker bands.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento