How Is Nitinol Used

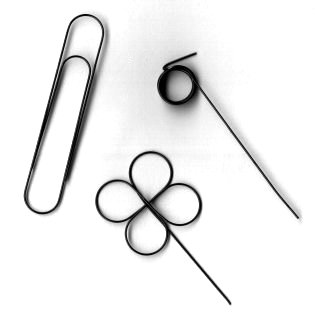

Although many applications of Nitinol remain invisible to the general public, some are well known. Nitinol eyewear frames may be deformed significantly yet return to their original shape. Several years ago, mobile telephones featured retractable antennas manufactured from Nitinol, which could bend without breaking or becoming permanently distorted.

Several applications utilise the shape memory capability of Nitinol. A recognised computer manufacturer employed a Nitinol mechanism for ejecting PCMCIA cards. Nitinol is used in couplings that join the ends of hydraulic hoses in aircraft. In a less serious application, Nitinol permits spoons to be bent when immersed in hot water.

The superelastic properties and biocompatibility of Nitinol render it a suitable material for a range of implanted medical devices. A familiar device is the stent, which supports and maintains the patency of blood vessels. Owing to Nitinol’s superelasticity, medical devices such as stents or heart valves can be compressed to fit inside a catheter. The catheter is positioned at the intended anatomical site; the device is released and reverts to its original shape.

The same superelasticity renders Nitinol the exclusive material suitable for stents deployed in the carotid artery or in the blood vessels of the legs. At these vulnerable sites, an impact may deform a stent temporarily. However, a Nitinol stent reverts to its designated shape. Stents constructed from alternative materials would be crushed or permanently deformed by such an impact.

Surgical instruments and components manufactured from Nitinol meet many requirements, particularly in minimally invasive or arthroscopic procedures. They utilise the advantages of Nitinol’s superelasticity and fatigue resistance. A curved tool is straightened and inserted through a cannula or a rigid tube. After exiting the cannula, the tool re-assumes its original shape. The surgeon conducts the procedure; subsequently, the tool is retracted into the cannula, where it returns to a configuration that facilitates its removal.

Read more: Nitinol - a shape memory alloy

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento