How Niobium Applies For Glasses, Money And Lamps?

Niobium is a chemical element. It is a soft, grey and ductile transition metal that occurs in pyrochlore and columbite minerals. Its name derives from Greek mythology, originating from Niobe, the daughter of Tantalus. The physical and chemical properties of niobium and tantalum overlap. This overlap renders analytical distinction challenging.

Niob for Glass

Lithium niobate is a ferroelectric material used in mobile telephones, optical modulators and in the manufacture of acoustic surface wave devices. It belongs to the ABO3 structure of ferroelectrics such as lithium tantalate and barium titanate. Niobium capacitors are available as an alternative to tantalum capacitors, although tantalum capacitors remain more common. Niobium is added to glass to increase the refractive index. This adjustment permits the production of finer and lighter corrective lenses.

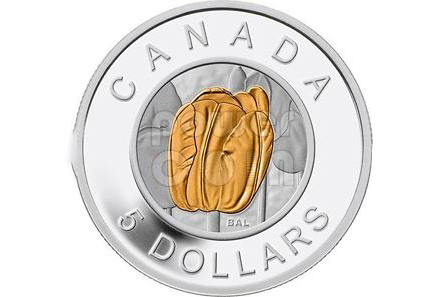

Niob for Coins

Niobbleche are utilised as a noble metal in commemorative coins, often combined with silver or gold. In 2003, Austria produced a series of silver coins incorporating niobium. Their colour is produced by the diffraction of light on a thin layer of anodised oxide. In 2012, ten coins displayed a range of colours in their central design: blue, green, brown, violet, purple or yellow. The Austrian commemorative coin of the Österreichischen Alpenbahnen (25 and 150 Euro) and the 2006 Austrian commemorative coin (25 Euro) serve as additional examples. In 2004 the Royal Canadian Mint commenced production of a 5-dollar coin named Hunter's Moon, which combined silver and niobium. During manufacture, niobium is selectively oxidised. This process yields surfaces that are distinct, whereby no two pieces are identical.

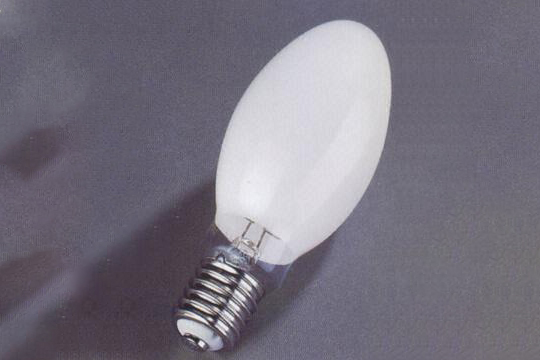

Niob for Lamps

The burner assemblies of high-pressure sodium vapour lamps are manufactured using niobium powder. This powder is sometimes alloyed with 1 % zirconium. Niobium has a thermal expansion coefficient that closely resembles that of sintered aluminium oxide burner ceramics. The ceramic material is translucent and resists chemical attack as well as reduction by hot liquid sodium and sodium vapour in the lamp.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento