Iridium: Civilian Hero In Precious Metals

Introduction:

Reports indicate that some traders use iridium to alter the apparent mass of gold from 20 grams to 25 grams. Iridium shares several elemental characteristics with gold and is used as an economic alternative.

This article investigates the properties of iridium, its role among precious metals, and its various applications in multiple industries.

Within the family of precious metals:

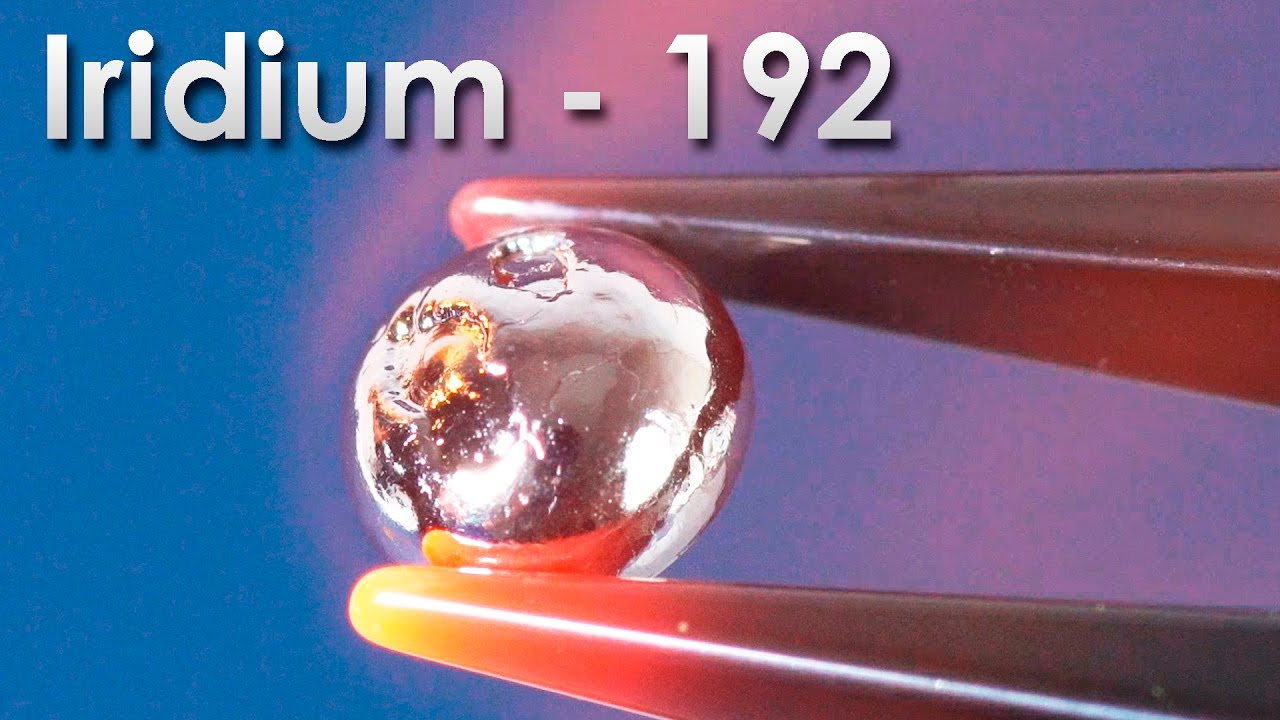

Iridium has an atomic number of 77 and an atomic weight of 192,22. It is a member of the platinum group. It occurs only in a concentration of 1 in 1 000 000 in the Earth’s crust. It is frequently found in association with platinum group elements in alluvial deposits and ore formations. This rarity contributes to the high value that iridium commands within the precious metals spectrum. For further details, please refer to the Iridium page.

Recovery and Recycling:

As a member of the platinum group, iridium is processed through established recycling measures. Platinum is retrieved from spent catalyst converters, broken items, and discarded electrical components. Lead, rhodium, osmium and ruthenium are processed by leaching, calcining, melting, distillation and dissolution to yield iridium powder. This recycling process utilises resources systematically and highlights the economic importance of iridium.

Multi-purpose Properties:

Iridium has a density of 22,65 grams per cubic centimetre, making it the densest known element. Its melting point is 2454 ℃. This property permits its use in high-temperature environments operating from 21 to 2200 ℃. At lower temperatures, iridium displays sufficient plasticity.

Iridium is the most corrosion-resistant metal and shows no reaction to common corrosive substances. It does not dissolve in mineral acids and remains unaffected by other metal melts. Additionally, it functions as a catalyst in reactions involving organic compounds.

Applications Across Industries:

Due to its high melting point and resistance to corrosion, iridium is employed in several industrial sectors. It is used in aerospace, pharmaceuticals and the automotive industry. It was initially employed in the manufacture of ballpoint pen tips. It is also used for injection needles, weighing scales, compass supports and electrical contacts.

In chemical laboratories, iridium is used in the production of equipment such as crucibles, electrodes and resistance wires made from platinum-iridium alloys. The iridium crucible is employed to grow oxide crystals that can withstand high temperatures for thousands of hours.

Specialised Applications and Developments:

Beyond conventional uses, iridium is used in specialised processes. It is employed as a container for radioactive heat sources. It is under study for use in producing oxide layers, thereby contributing to developments in colour technology. Ir192, an iridium isotope, is used as a gamma ray source in non-destructive testing and radiochemical therapy. These applications illustrate the evolving uses of iridium.

Conclusion:

In summary, iridium is an important element within the realm of precious metals. It offers economic advantages in specific processes and is used in various industries. Its rarity, high density, corrosion resistance and capacity to operate at extreme temperatures make it a raw material of note. Initially used for ballpoint pen tips, it has since been adopted in aerospace and healthcare applications. Further research by institutions such as Stanford Advanced Materials and companies like Oceania International LLC has documented a practical history of innovation and application in the field of precious metals.

Eric Smith and Chin Trento have contributed data that confirm these applications. Detailed studies from Stanford Advanced Materials (SAM) support these findings.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento