What Are The Properties And Industrial Benefits Of Molybdenum?

Due to its unique mechanical and chemical properties, Molybdenum has become a material that meets strict requirements. Its advantages include a high melting point, a low thermal expansion coefficient and good thermal conductivity. Consequently, it is used in various industrial sectors.

Molybdenum is utilised in a range of applications among specialised materials. It is employed in the industrial belt and filament manufacturing, in power electronics with semiconductor substrates, in high-temperature glass melt electrodes and in solar cell and flat-panel display sputter coating using palladium materials.

The industrial application of Molybdenum varies according to the type of material. There are three main types:

High Purity and Creep Resistance

Molybdenum exhibits a high purity level. It withstands extremely high temperatures and remains easy to process. It is used in the manufacture of crucibles for conventional sapphire growth methods. Given its purity, Molybdenum has been used to optimise melting and solidification containers.

Good Dimensional Stability and Corrosion Resistance

Our stirring devices uniformly circulate various glass melts. They must resist extreme temperatures and corrosive glass melts. Molybdenum demonstrates dimensional stability and corrosion resistance when exposed to metal and glass melts. Consequently, it provides mixing performance and extends product lifespan.

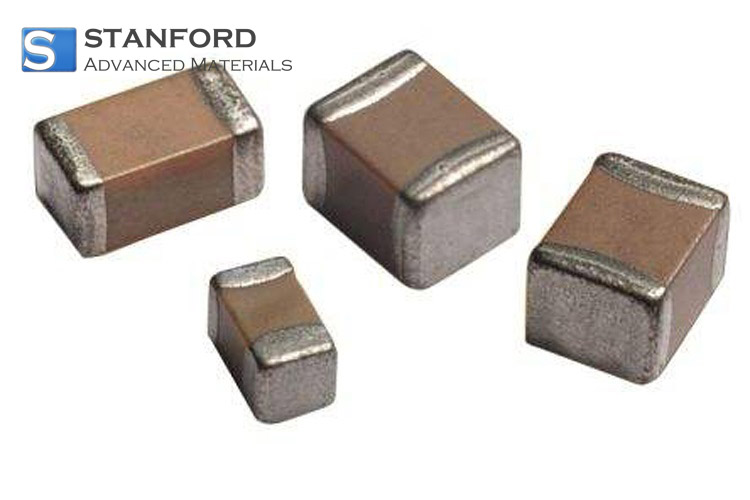

High Thermal Conductivity and Low Thermal Expansion Coefficient

High power density and current in power diodes and transistors generate heat. Molybdenum and its alloys are used as substrate materials for power electronics. They exhibit thermal conductivity and thermal expansion behaviour that are compatible with the corresponding semiconductor materials. When used as a substrate, Molybdenum dissipates heat reliably.

Conclusion

We thank you for reading our article. We hope it assists in understanding the industrial applications of Molybdenum. If you require further information, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of Molybdenum and has over two decades of experience in the manufacturing and distribution of Molybdenum products. Its products meet the research and development and production requirements of its customers. We expect that SAM will serve as your Molybdenum supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

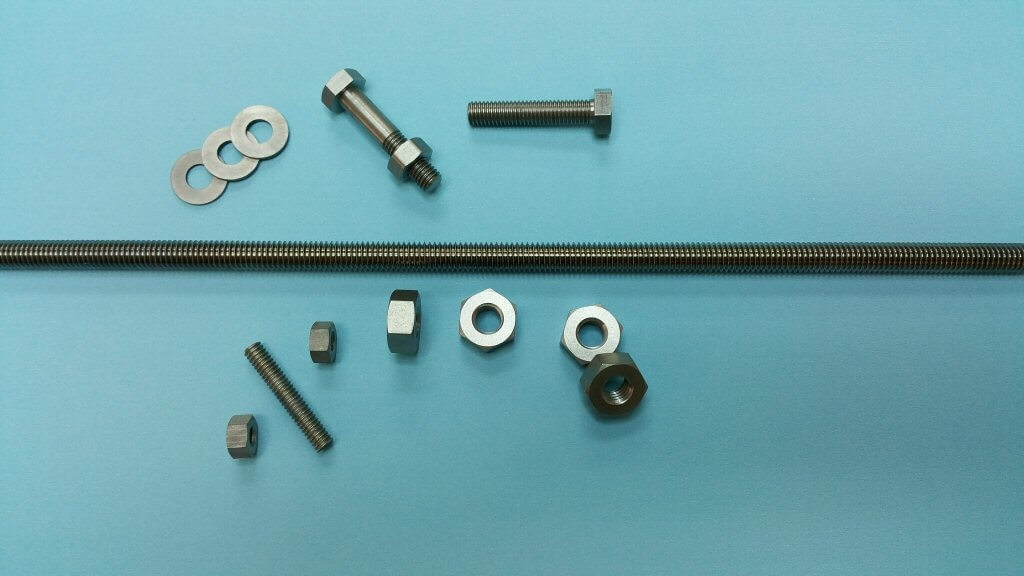

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento