Main Applications Of W-Cu Composites

Because Wolfram (W) demonstrates a favourable electron emission characteristic, a category of composite materials – such as Wolframlegierungen and W-Cu-Verbundwerkstoffen – has been employed as an electrode material in electrical discharge machining, for current collection in electric locomotives, in ultra-high voltage switches and during welding in the electricity sector.

Main applications of W-Cu composites

For example, the Wolfram-Rhenium-Legierung has on numerous occasions replaced Platin as a thermocouple material. The Wolfram-Rhenium wire, as detailed on Wolfram-Rhenium-Draht, is used as an electron-emitting material in cathode ray tubes that have been introduced in thousands of households. In addition, Chrom, Vanadium and other materials are frequently utilised in electron microscopy for the coating of glass.

This article examines the principal applications of W-Cu composites.

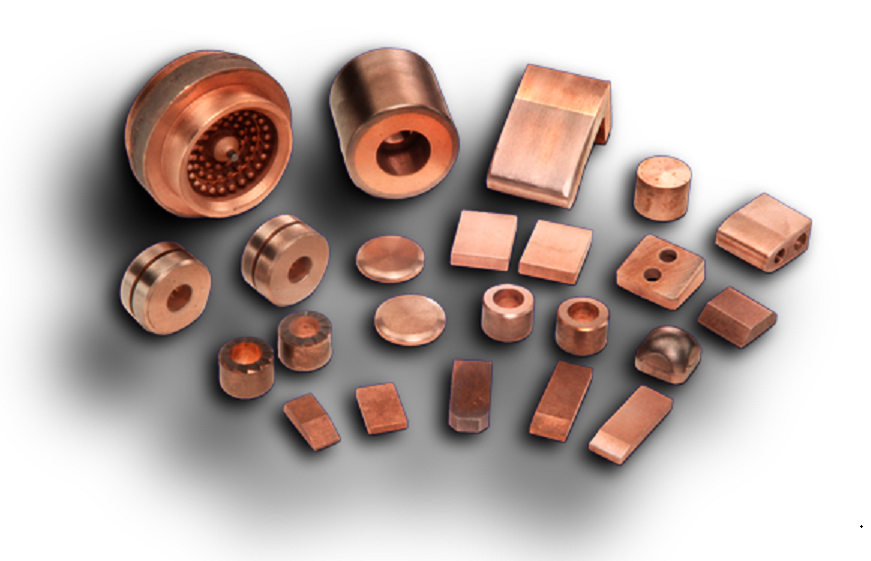

Tungsten is characterised by high hardness and possesses the highest melting point among metals, while Kupfer (Cu) is well known for its high electrical and thermal conductivity. The W-Cu composite further provides high electrical and thermal conductivity, a low coefficient of thermal expansion and marked resistance to arc corrosion. Consequently, it has long been used as a material for electrical contacts, electrical discharge machining, resistance welding and plasma electrodes. With the development of microelectronic information technology, the W-Cu composite has been incorporated into very-large-scale integrated circuits and high-performance microwave devices.

-

W-Cu composite for electrical contacts

Given that the melting point of tungsten (3 390–3 430 ℃) considerably exceeds the boiling point of copper (2 350–2 600 ℃), the copper in tungsten-copper composites solidifies and maintains the integrity of the tungsten framework by dissipating heat generated under the influence of a high-temperature arc. Consequently, reliable interruption of the electrical contact is achieved.

The W-Cu composite exhibits strong resistance to arc corrosion, fusion welding and voltage stress. It is thus particularly suited for high-voltage and ultra-high vacuum opening and closing contacts, as found in vacuum switching devices and modern high-voltage equipment using SF6 as an arc extinguishing medium.

-

W-Cu composite for electronic housings and heat sinks

The rapid development of IC chip technology has imposed increasingly demanding requirements on IC packaging materials. In addition to needing a thermal conductivity of up to 170–190 W/(m·K) and a low, precisely adjustable coefficient of thermal expansion, these materials must be straightforward to process and cost-effective to form. The thermophysical parameters of the W-Cu composite can be readily adjusted, thereby extending its application in microelectronic devices so that it is employed as an effective heat sink material in high-performance equipment.

The appropriate coefficient of thermal expansion can be aligned with semiconductor materials such as silicon chips, gallium arsenide and ceramics in microelectronic applications, thereby avoiding damage from thermal fatigue. Furthermore, the W-Cu composite can be manufactured to its final dimensions, enabling device miniaturisation.

-

W-Cu composite for electrode machining

The development of various advanced techniques for electrical machining represents another significant application area for tungsten-copper composites, given their high heat resistance, electrical conductivity, thermal conductivity and resistance to arc erosion.

Copper and its alloys have been extensively used as machining electrodes in electrical discharge machining over a long period. Although copper and copper alloys are cost-effective and readily available, the rate of electrode wear is high and machining precision is low because these materials lack adequate erosion resistance. Therefore, under many circumstances they do not meet the stringent requirements of specialised machining.

Conclusion

We thank you for reading this article and trust that it has enhanced your understanding of the principal applications of W-Cu composites. Should you require further information about W-Cu composites, please visit Stanford Advanced Materials for additional details.

Stanford Advanced Materials (SAM) is a global supplier of tungsten products with over two decades of experience in the manufacture and distribution of W-Cu composites. We supply W-Cu composites that meet the research and production requirements of our customers. We are convinced that SAM will be your preferred supplier and business partner for W-Cu.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento