Separation Of Zirconium And Hafnium

What is Zirconium?

Zirconium (Zr) is an element with atomic number 40 and an atomic weight of 91.224. Most zirconium is obtained by refining the mineral zircon. It is used in the nuclear industry due to its low neutron-capture cross section. Zirconium is manufactured in the form of zirconium alloys, typically Zircaloy‑2 and Zircaloy‑4, for the production of fuel rods for nuclear reactors.

Owing to the chemical corrosion resistance of zirconium, forms such as zirconium tubes and plates are used in the manufacture of equipment for the chemical industry. Zirconium is also added to steel, and zirconium oxide, sometimes referred to as zirconia, is employed in the production of ceramics.

What is Hafnium?

Hafnium, an element in the same group as zirconium, has a higher density and a considerably larger neutron-capture cross section. The hafnium content in Zircaloy products must be kept very low for applications in the nuclear industry.

What is Zircon?

Zircon, an important resource for pure zirconium, typically contains some hafnium. The separation of zirconium and hafnium is extremely challenging because the two elements share similar chemical properties.

Typically, a liquid extraction method is applied to separate zirconium and hafnium, and several systems have been developed. Salt melt distillation has also been used in the separation process. These procedures are more expensive than conventional metal purification techniques. Furthermore, liquid extraction consumes a large quantity of water and generates considerable waste.

In general, it is unnecessary to remove all hafnium from zirconium unless it is intended for use in the nuclear industry. Consequently, products with low hafnium content may be difficult to obtain on the general market. Although the process of reducing zirconium with Magnesium is usually less expensive, high-purity zirconium is still produced in the form of Zr crystal bars. The market price for zirconium with low hafnium content may be 50 to 100 per cent higher than that for zirconium with high hafnium content.

How are Hafnium and Zirconium separated?

Three principal procedures are employed in the extraction and purification of zirconium from hafnium. The first method is pyrolysis separation, which utilises the difference in vapour pressure between zirconium and hafnium chlorides at elevated temperatures or pressures. This method replaces multiple production steps, thereby contributing to an efficient production process with minimal environmental impact.

The second technique is solvent extraction. This method employs a range of extractants, including ketones, phosphorous‑containing agents and amine‑based agents. It permits scalable and continuous operation and achieves the purity levels required by various industries.

The ion exchange technique, which is less commonly employed, separates zirconium and hafnium via ion exchange. This method is used on a limited scale, particularly for smaller production quantities. For example, it was used in the former Soviet Union to further separate hafnium from hafnium‑rich material produced by the zirconium‑hafnium recrystallisation method. The purified hafnium oxide served as a precursor for the production of hafnium sponge.

These methods provide targeted solutions to meet the stringent purity requirements for zirconium applications in various sectors. Further detailed information is available at https://www.samaterials.co.uk/.

Conclusion

Stanford Advanced Materials supplies high-purity crystalline zirconium bars as a source of zirconium. Products with both low and high hafnium content are available. The hafnium content of our crystal bars can be below 250 ppm.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

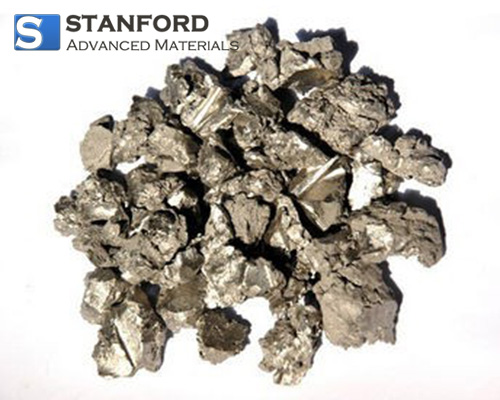

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento