What Role Does The Flake Graphite Play In Our Lives?

There are two types of graphite: natural graphite and artificial graphite. With improvements in manufacturing technology, the performance of artificial graphite in many cases is not inferior to that of natural graphite. However, natural graphite still retains advantages in certain applications.

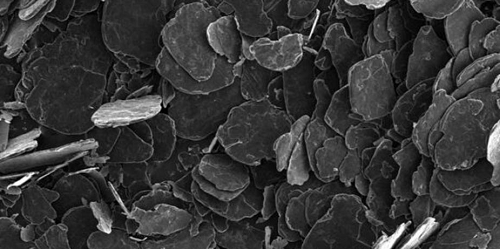

Among natural graphite deposits, flake graphite (crystalline graphite) presents a low storage capability, high material value, efficient thermal conductivity, lubricity and oxidation resistance. It is employed in metallurgy, mechanical engineering, the chemical industry, refractory materials, aerospace and other sectors, and it is one of the key non-metallic materials in modern high-technology development.

Due to its flake structure and consistent surface properties, flake graphite is among the more buoyant minerals found in nature. With the development of heating and acid leaching techniques, the purity of graphite has increased steadily. When the purity attains levels between 99% and 99,99% or more, it is applied in carbon composite materials, the electronics industry, friction materials, lubrication and other fields.

Graphene

Graphene is a type of carbon material with a large specific surface area and broad application potential. Its specific capacity, cost efficiency and lifespan have been measured to be higher than those of alternative products.

The selection of raw materials depends largely on both the product type and the processing method. For mechanical exfoliation, epitaxial growth and the graphite oxide reduction method, natural (crystalline) flake graphite is used. In the production of graphene, large-flake graphite is more advantageous. For graphene thin films produced through gas deposition, the raw material is a carbonaceous gas unrelated to graphite.

Expanded Graphite

Expanded graphite (EG), a recently introduced functional carbon material, is a loose, porous and worm‐shaped material obtained from natural graphite flakes through intercalation, washing, drying and high-temperature expansion. In the manufacture of expanded graphite, large-grained graphite must be used; fine-grained graphite is either unsuitable or difficult to process.

In addition to the properties of natural graphite – resistance to low and high temperatures, corrosion resistance and self-lubrication – expanded graphite exhibits attributes such as softness, compressive strength, adsorption capacity, environmental coordination, biocompatibility and radiation resistance, which natural graphite does not display. Consequently, expanded graphite is employed in applications including refractory fillers, medical bandages and as flexible graphite for sealing materials.

Graphite as a Cathode Material for Batteries

Graphite offers conductivity that is 100 times higher than that of typical non-metallic minerals. It is the most commonly used cathode material for lithium-ion batteries. Both flake graphite and artificial graphite can serve as anode materials for batteries, with each type having distinct advantages. Conversely, earth-like graphite is not suitable as an anode material because of its low capacity.

Flake graphite offers benefits such as a low price, high electronic conductivity, an elevated lithium-ion diffusion coefficient, significant intercalation capacity and a low intercalation potential. However, its application requires strict control of the processing environment and technology. In contrast, although artificial graphite is expensive, its application threshold is lower, it does not require advanced processing technology and its market presence is increasing rapidly. In mobile phone and camera batteries, both crystalline and artificial graphite are used in approximately equal proportions.

Refractory Material

Flake graphite exhibits stable performance over temperature cycles and demonstrates resistance to slag erosion. Its products also maintain high-temperature stability and significant strength. Consequently, it is used in applications such as protective linings in steel production, metallurgical furnace linings, magnesia carbon bricks and graphite crucibles, among other uses.

Lubricant Material

The effective lubricity of graphite derives from its crystal structure. Large-grained graphite provides better lubricity than fine-grained graphite. The greater the particle size, the lower the friction coefficient and the better the lubricity observed.

Flake graphite is frequently used as a lubricant in the mechanical industry. Graphite emulsions produced by deep drawing are effective in several metal processing operations, such as wire drawing and tube drawing. Moreover, lubricants tend to perform poorly under high speed, high temperature and high pressure. In contrast, wear-resistant graphite materials can operate at temperatures between 200℃ and 2 000℃ and at high speeds without additional lubricants. In many corrosive environments, graphite materials are also used to fabricate piston cups, sealing rings and bearings, thereby eliminating the need to add lubricants during operation.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento