Ultimate Guide To Heat Resistant 3D Printing Materials: Top 10 Picks

Introduction

The field of 3D printing has developed rapidly and now offers a wide range of material options, particularly for applications that require heat resistance. Whether the application involves automotive parts, aerospace components or consumer goods, the selection of the appropriate heat‐resistant material is critical. In this guide we present the 10 heat‐resistant materials for 3D printing, outlining their properties, applications and technical details.

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is a thermoplastic polymer composed of acrylonitrile, butadiene and styrene molecules. It combines the stiffness of acrylonitrile–styrene polymers with the toughness of polybutadiene rubber. The material exhibits high impact resistance, good mechanical toughness and a balanced ratio of hardness to gloss. ABS is resistant to aqueous acids, bases, concentrated saline and phosphoric acids, alcohols, as well as animal, plant and mineral oils, although its resistance to solvents is limited.

Technology: Fused Deposition Modeling (FDM)

Key properties: Good strength, heat resistance and ductility.

Applications: Automotive parts, consumer goods and electronic enclosures.

2. ULTEM (PEI - Polyetherimide)

ULTEM, or Polyetherimide (PEI), is a high-performance technical thermoplastic that exhibits an amber, translucent appearance. It provides high mechanical strength, a wide range of chemical resistance, good penetration resistance and excellent thermal stability. ULTEM retains its properties over a broad temperature range and is inherently flame-retardant. It is also recognised for its dimensional stability and electrical insulating characteristics.

Technology: FDM, SLS (Selective Laser Sintering)

Key features: High heat resistance, strength and flame retardancy.

Applications: Aerospace components, automotive parts, medical devices and electrical components.

3. PP (Polypropylene)

Polypropylene is a lightweight and durable thermoplastic polymer known for its resistance to a variety of chemicals, including solvents, bases and acids. It has a high melting point, making it suitable for items exposed to heat. PP is noted for its flexibility, excellent electrical insulation and good fatigue resistance. It is frequently employed in applications that require repeated bending, such as living hinges.

Technology: FDM, SLS

Key properties: High fatigue resistance, elasticity and chemical resistance.

Applications: Automotive parts, consumer goods and packaging materials.

4. Metal Filaments

Metal filaments consist of fine metal powders combined with a plastic polymer binder. They enable the 3D printing of metal parts by uniting the conventional filament extrusion process with post-processing techniques such as sintering. The process involves producing parts that exhibit thermal and electrical conductivity similar to metals. The printed parts usually require sintering in a high-temperature oven to remove the binder and fuse the metal particles, thereby producing a dense metal component.

Technology: FDM for composite filaments, Direct Metal Laser Sintering (DMLS) for full metal parts.

Key features: High strength and heat resistance; post-processing is required.

Applications: Aerospace components, automotive parts and specialised tools.

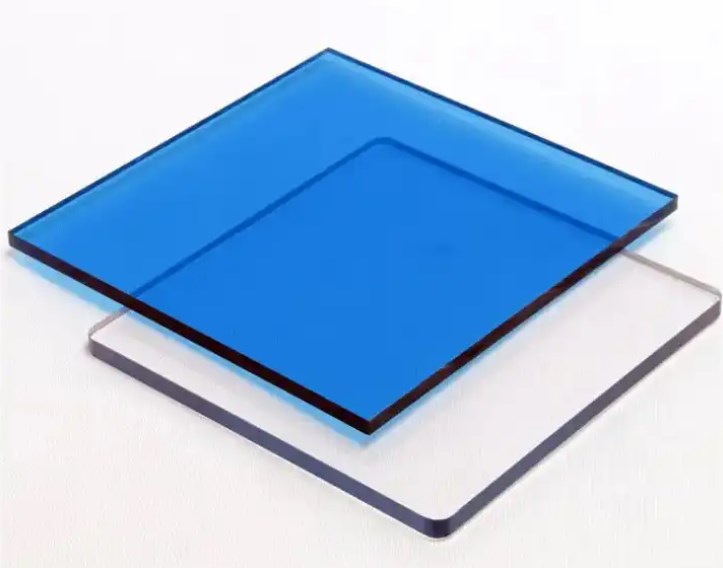

5. Polycarbonate (PC)

Polycarbonate is a high-performance thermoplastic known for its clarity, impact resistance and heat tolerance. It transmits over 90% of light, is optically clear and resists breakage. PC maintains its properties under high-temperature conditions. This material is used in applications that demand high performance and reliable operation.

Technology: FDM, SLA (Stereolithography)

Key properties: Excellent toughness, heat resistance and optical performance.

Applications: Protective equipment, automotive components and optical lenses.

6. PEEK (Polyetheretherketone)

PEEK is a semi-crystalline thermoplastic that retains its mechanical and chemical resistance properties even at high temperatures. It is among the few plastics that are suitable for ultra-high vacuum environments. PEEK demonstrates strong resistance to thermal degradation as well as to both organic and aqueous chemical exposures. It is employed in demanding engineering applications where a high strength-to-weight ratio is required.

Technology: FDM, SLS

Key properties: Outstanding thermal stability, chemical resistance and mechanical strength.

Applications: Aerospace, medical implants and high-performance automotive components.

7. Aluminium AlSi10Mg

Aluminium AlSi10Mg is a common aluminium alloy used in additive manufacturing. It combines the lightweight nature of aluminium with the thermal conductivity of silicon and the strength of magnesium. This alloy is known for good formability, an excellent strength-to-weight ratio and favourable thermal properties. It is typically used in applications that demand corrosion resistance and good weldability.

Technology: Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM)

Key features: Low weight, satisfactory thermal performance and corrosion resistance.

Applications: Automotive components, aerospace parts and consumer electronics.

8. Stainless Steel 316L

Stainless Steel 316L is a molybdenum-containing austenitic stainless steel that offers improved resistance to chloride-induced corrosion when compared with other chromium–nickel stainless steels. It is noted for its excellent toughness, even under cryogenic conditions. This grade is frequently used in environments exposed to aggressive chemicals and is prevalent in the food and medical industries.

Technology: DMLS, SLM

Key features: High corrosion resistance, satisfactory mechanical properties and weldability.

Applications: Medical devices, marine applications and chemical processing equipment.

9. Inconel 718

Inconel 718 is a nickel–chromium alloy employed for its high strength, good corrosion resistance and its ability to withstand extreme temperatures. The alloy exhibits reliable tensile, fatigue, creep and fracture strength at temperatures up to approximately 700°C (1 290°F). It is used in high-load applications such as turbine engines, rocket motors and nuclear reactors.

Technology: DMLS, SLM

Key features: Excellent mechanical strength, corrosion resistance and thermal stability.

Applications: Engine components for aerospace, turbine applications and high-temperature processes.

10. Carbon Fibre

Carbon fibres consist of strands of carbon atoms arranged in a crystalline structure. They are known for high stiffness, high tensile strength, low weight, excellent chemical resistance, high temperature tolerance and minimal thermal expansion. These properties mean that carbon fibres are used in aerospace, construction, military applications and motorsport, as well as in other competitive sporting equipment.

Technology: Frequently employed in composite formulations via the FDM process or in reinforced filaments.

Key features: High strength-to-weight ratio, stiffness and thermal conductivity.

Applications: Aerospace, automotive industry and sports equipment.

Properties of heat‐resistant 3D printing materials

The table below lists the melting point, glass transition temperature and tensile strength for the ten heat‐resistant 3D printing materials:

|

Material |

Melting point |

Glass transition temperature |

Tensile strength |

|

ABS |

200°C |

105°C |

42,5 – 44,8 MPa |

|

ULTEM (PEI) |

340°C |

216°C |

105 MPa |

|

PP (Polypropylene) |

160 – 170°C |

–10°C |

32 – 40 MPa |

|

Metal Filaments |

Variable (depends on the metal used) |

Variable |

Variable |

|

PC |

230 – 260°C |

147°C |

60 MPa |

|

PEEK |

343°C |

143°C |

110 MPa |

|

Aluminium AlSi10Mg |

670°C |

Not applicable |

450 MPa |

|

Stainless Steel 316L |

1 400°C |

Not applicable |

520 – 690 MPa |

|

Inconel 718 |

1 370 – 1 430°C |

Not applicable |

965 MPa |

|

Carbon Fibre |

Not applicable |

Not applicable |

3 500 – 7 000 MPa (for carbon fibre composite materials) |

Please note:

For materials such as metal filaments and carbon fibres, properties may vary considerably depending on the composite formulation.

The term “Not applicable” is used where a particular property (for example, the melting point of carbon fibres) is irrelevant or where no defined value exists.

Costs for heat‐resistant 3D printing materials

The following table presents a cost comparison for the specified heat‐resistant 3D printing materials:

|

Material |

Approximate cost |

Price range per kg |

|

ABS |

Low to moderate |

$20 – $100 |

|

ULTEM (PEI) |

Moderate to high |

$100 – $200 |

|

PP (Polypropylene) |

Low to moderate |

$50 – $100 |

|

Metal Filaments |

High |

$100 – $1 000 |

|

PC |

Moderate to high |

$50 – $1 000 |

|

PEEK |

High |

$300 – $1 000 |

|

Aluminium AlSi10Mg |

High |

$200 – $1 000 |

|

Stainless Steel 316L |

Moderate |

$50 – $1 000 |

|

Inconel 718 |

High |

$300 – $1 000 |

|

Carbon Fibre Filaments |

Moderate to high |

$100 – $1 000 |

These prices are indicative and may vary according to factors such as quality, supplier, location and market conditions. For the most accurate and up-to-date pricing, please contact us.

Conclusion

The selection of an appropriate heat‐resistant material for 3D printing depends on the specific technical requirements, including thermal load, mechanical stress and environmental conditions. Each of these 10 materials offers specific properties and advantages. By understanding these properties, you can improve the performance of 3D printing in high-temperature applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento