3 Important Things About Tantalum Capacitor

Introduction

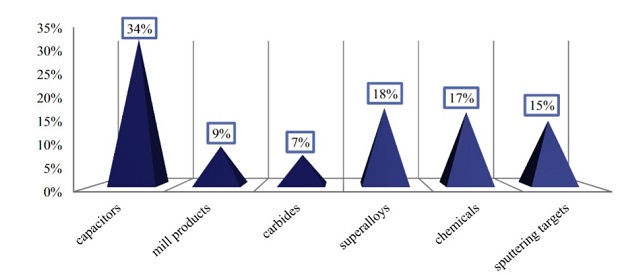

Tantalum (Ta) is a rare, hard, bluish‐grey and lustrous transition metal. It is highly resistant to corrosion and conducts both heat and electricity efficiently. It exhibits excellent resistance to aggressive aqua regia at temperatures below 150°C. Given its stable physical and chemical properties, tantalum is predominantly employed in the electronics sector, in alloy formulations and in other industrial applications. Figure 1 shows the product shipments of tantalum in 2016 [1]. The majority of tantalum is utilised in capacitors as anodes, while other uses include alloys, chemicals and Sputtertargets. In 2021, approximately 70 % of tantalum demand originated from the electronics industry, including capacitor anodes, semiconductor targets and sintered anode coatings [2]. We will now discuss tantalum capacitors.

Figure 1: Product shipments of tantalum in 2016 [1]

How is a Tantalum Capacitor Manufactured?

Similar to other capacitors, a tantalum capacitor comprises three components: an anode, a cathode and an electrolyte. The anode is manufactured using pure tantalum powder and wires.

The tantalum powder is packed around a tantalum wire to form a pellet. Subsequently, the pellet is sintered at approximately 1 200 to 1 800°C to remove impurities. During this process, the powder adopts a porous structure, thereby increasing the capacitance. Tantalum capacitors offer a higher capacitance per volume compared with other capacitor types, for example, aluminium capacitors.

After sintering, a dielectric is formed on the surface of the tantalum particles by converting the outer tantalum layer to Ta2O5. This process is referred to as anodisation. The thickness of the dielectric is directly related to the capacitor’s voltage withstand rating. A safety margin is integrated in the oxide layer thickness to ensure reliable operation.

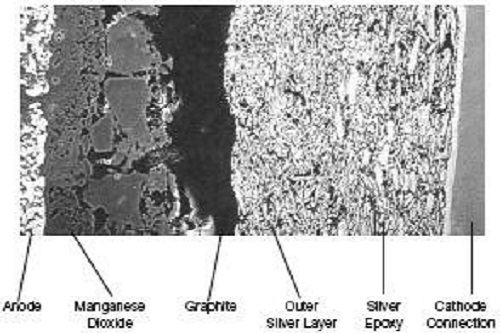

The final step is the addition of a cathode outside the dielectric. In wet tantalum capacitors, a liquid electrolyte is applied by immersing the tantalum component, and the capacitor is then enclosed in a case. The case and the liquid electrolyte function as the cathode. For solid tantalum capacitors, the anode is immersed in a Mn(NO₃)₂ solution and heated at approximately 250°C, thereby forming a MnO₂ layer on the outer surface of the dielectric. This procedure is repeated several times until a sufficiently thick MnO₂ layer is generated around the pellet. Subsequently, the pellet is immersed in graphite and silver to create a reliable connection between the MnO₂ cathode and the external cathode terminal. Figure 2 provides a brief overview of the tantalum capacitor.

Figure 2: Cross‐section of a solid tantalum capacitor

Advantages and Disadvantages of Tantalum Capacitors

Advantages

Tantalum capacitors exhibit improved frequency characteristics and longer operational lifespans compared with aluminium capacitors or ceramic multi‐layer capacitors. Their equivalent series resistance is lower, thereby allowing higher currents with reduced thermal generation. Furthermore, tantalum capacitors provide the highest capacitance per volume. Consequently, they are extensively used in electronic applications such as laptops and smartphones.

Disadvantages

Tantalum capacitors are not as prevalent as aluminium capacitors, multilayer ceramic capacitors (MLCCs) or niobium capacitors. One reason is that the supply and price of tantalum metal are unstable. In some instances, MLCCs serve as replacements for small tantalum capacitors and aluminium capacitors for larger tantalum capacitor applications.

Because they are polarised, tantalum capacitors can only be used with direct current rather than alternating current. Voltage spikes may cause contact between the anode and the MnO₂ cathode, resulting in hazardous failures, including chemical reactions that emit smoke and flames. Consequently, tantalum capacitors should be paired with current limiters or thermal fuses.

Applications of Tantalum Capacitors

Tantalum capacitors are primarily utilised because of their high capacitance per volume, stability and satisfactory frequency characteristics. They are capable of replacing aluminium electrolytic capacitors in military applications. They are also used in medical electronics owing to their precise capacitance constancy. Within electronic products, desktop PCs and laptops employ the largest quantities of tantalum capacitors. By contrast, smartphones and mobile phones incorporate only a limited number of tantalum capacitors.

Tantalum Recycling

The increasing consumption of tantalum products generates substantial quantities of tantalum‐containing waste. Production waste from the manufacture of superalloys and sputter targets, as well as waste from the electronics sector at the end of its service life, has increased significantly. Conversely, the gap between the supply and demand of tantalum has widened. To address this shortfall, recycling of tantalum waste is now being redeveloped.

Recycling may be categorised into two types: pre‐consumer recycling and post‐consumer recycling [3]. Most tantalum is recycled from pre‐consumer scrap because it is only minimally contaminated and presents fewer challenges. Pre‐consumer recycling can improve the entire production process by reducing the generation of mineral waste. Tantalum concentration, cleaning costs, size and economic feasibility are the key factors influencing recycling strategies.

Post‐consumer recycling of tantalum is less developed given the low concentration of tantalum compared with other metals such as Cu and Au. In the pyrometallurgical processing of tantalum products, post‐consumer recycling is highly complex. The small size of tantalum capacitors further complicates this process. Further research is required to develop an economically viable and environmentally friendly method for recycling tantalum products after use.

Citation

- Agrawal, M., Singh, R., Ranitović, M., Kamberovic, Z., Ekberg, C. and Singh, K. K. (2021). Global market trends for tantalum and recycling methods for tantalum waste capacitors: A review, Sustainable Materials and Technologies, 29, e00323.

- Zogbi, D. M. (2021, 10/05/2021). The Tantalum Supply Chain: Update of the Global Market 2021. TTI, Inc. Retrieved on 04/01/2023, from https://www.tti.com/content/ttiinc/en/resources/marketeye/categories/passives/me-zogbi-20211005.html

- Agrawal, M., Singh, R., Ranitović, M., Kamberovic, Z., Ekberg, C. and Singh, K. K. (2021). Global market trends for tantalum and recycling methods for tantalum waste capacitors: A review, Sustainable Materials and Technologies, 29, e00323.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento