A Beginner's Guide To Composite Materials

Description

Composite materials combine two or more distinct constituent materials to form a new material with improved properties. Typically, one component provides strength, whereas another contributes flexibility or durability. In summary, composite materials utilise each constituent’s properties. They may be as simple as glass fibre or as advanced as carbon fibre-reinforced polymers, which are employed in aerospace and the automotive sectors.

-What are Composite Materials?

Composite materials are produced by combining two or more different substances to create a product with properties that are not present in the original materials. They typically consist of a matrix (binder) and a reinforcement phase. The matrix bonds the reinforcement, while the reinforcement contributes strength and stiffness. This formation yields materials that are strong and lightweight, and they are used in many engineering applications.

-Types of Composite Materials

Composite materials can be broadly classified according to the matrix material employed:

Polymer matrix composites (PMCs): These are the most commonly used composites. A polymer resin (e.g. epoxy) serves as the matrix and reinforcement fibres such as glass or carbon provide strength. PMCs are widely used in automotive and aerospace manufacturing given that they offer a favourable strength-to-weight ratio.

Metal matrix composites (MMCs): Aluminium or titanium acts as the matrix, while ceramic fibres or particles provide reinforcement. They deliver enhanced mechanical properties and are used for high-temperature applications.

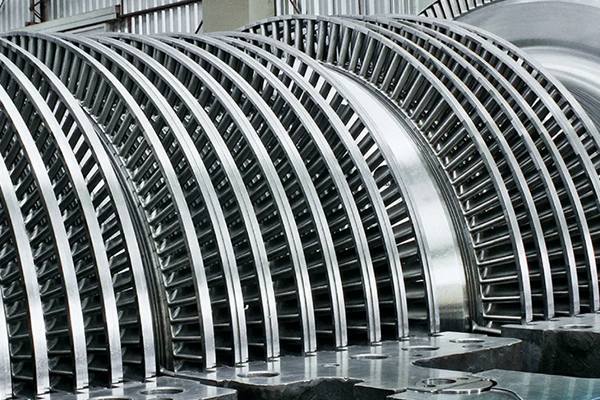

Composite materials with a ceramic matrix (CMCs): These composites use a ceramic matrix reinforced with silicon carbide fibres. CMCs exhibit heat resistance and are used in turbine engines and cutting tools.

Hybrid composite materials: Two different reinforcement types are combined within one matrix. This method enables adjustment of the material properties to meet specific requirements.

-Properties of Composite Materials

The combination of reinforcement and matrix imparts composite materials with several significant properties:

High strength-to-weight ratio: Composite materials offer strength comparable to conventional materials such as steel while maintaining a much lower mass, thereby contributing to weight reduction in critical applications.

Corrosion resistance: Most composite materials are more resistant to corrosion than metals, which extends the service life of components operating in harsh environments.

Design flexibility: Composite materials can be moulded into complex geometries. This capacity enables engineers to develop designs that meet specific technical requirements.

Tailored thermal and electrical conductivity: Composite materials can be engineered to exhibit specific thermal and electrical behaviours, ranging from insulative to conductive properties.

-Applications of Composite Materials

Composite materials are used in several industries due to their distinctive properties:

Aerospace: In the aerospace industry, composite materials are extensively employed for components such as fuselages and wings to reduce weight and thereby improve fuel efficiency.

Automotive: In automotive manufacturing, composite materials assist in producing lighter vehicles that perform efficiently and consume less fuel.

Construction: Composite materials are used in building components such as panels and bridges. They provide the required structural performance and help to reduce maintenance labour.

Sporting goods: Items such as tennis rackets, golf clubs and bicycles benefit from the strength and low mass of composite materials, which contributes to improved performance in sports.

Medical devices: Composite materials are employed in prosthetics and implants owing to their biocompatibility and ability to be produced to specified dimensions.

Table of Properties and Applications

|

Property |

Composite Material Example |

Primary Application |

|

Strength |

Carbon fibre-reinforced polymer |

Components for aerospace applications and high-performance sporting goods |

|

Lightweight |

Glass fibre-reinforced polymer |

Automotive trim and wind turbine blades |

|

Durability |

Aramid fibre composites |

Protective clothing, military applications |

|

Flexibility |

Polymer matrix composites |

Enclosures for consumer electronics and sports products |

|

Corrosion resistance |

Ceramic matrix composites |

Chemical processing plants and high-temperature environments |

This table summarises some of the principal properties of composite materials and indicates their common applications. The materials combine high strength with low weight, which makes them suitable for use in various engineering fields.

Frequently Asked Questions

Q: What exactly defines a composite material?

A: A composite material is produced by combining two or more distinct substances to create a material with properties that exceed those of the individual components.

Q: Are composite materials stronger than conventional metals?

A: In many cases they are. Composite materials, such as carbon fibre-reinforced polymers, can provide a high strength-to-weight ratio that surpasses conventional metals such as steel or aluminium.

Q: Can composite materials be recycled?

A: The recycling of composite materials remains challenging; however, advances in technology have progressively increased recycling efficiency. Ongoing research aims to develop more effective methods to recycle these materials.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento