All You Need To Know About Automotive Metals

Description

Learn more about the principal metals employed in automotive manufacturing. The content focuses on the measured properties of Titanium and presents a detailed comparative table of the materials used in vehicle production.

Metals and Vehicles

The production of motor vehicles relies significantly on the use of metals. Each metal is selected on the basis of its defined characteristics to ensure safety, durability, efficiency and affordability. Metals are used in chassis structures, engines and other mechanical systems. Selecting appropriate automotive metals requires consideration of strength, weight, corrosion resistance and manufacturing cost.

A central aspect in vehicle production is reducing weight without compromising safety or design. Aluminium, Magnesium, Steel and Titanium are key materials in achieving this objective. Light metals contribute to improved fuel efficiency, better handling and reduced emissions. These factors are critical in the modern, environmentally conscious automotive market.

Steel has traditionally been used because it is strong, readily available and relatively inexpensive. Advancements in material science have led to a greater use of lighter metals such as Aluminium and Magnesium in high-performance and electric vehicles. Titanium is chosen when a high strength-to-weight ratio and excellent corrosion resistance justify its elevated cost.

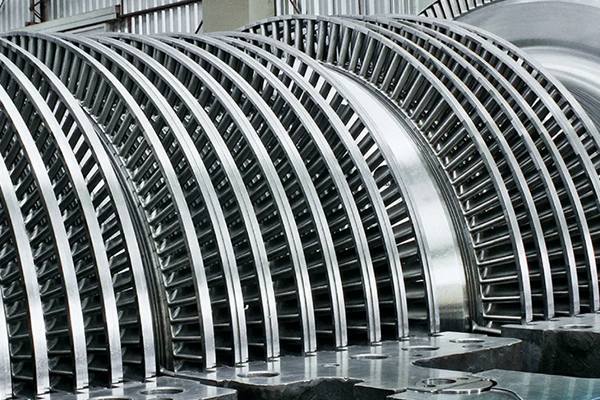

Titanium

Titanium is a metal noted for its measured strength, light weight and corrosion resistance. It is approximately 45% lighter than Steel while offering comparable strength. This makes it suitable for performance-critical components such as exhaust systems, suspension springs, valves and connecting rods.

Automotive manufacturers utilise Titanium alloys to reduce vehicle weight and improve performance as well as fuel consumption. Although Titanium incurs higher production costs and presents processing challenges, improved manufacturing methods are thereby reducing these costs. The corrosion resistance of Titanium extends its service life under demanding conditions. Its fatigue resistance renders it appropriate for safety-critical applications where longevity and reliability under heavy loads are required. Given that sustainability is increasingly significant, its recyclability supports its use in automotive applications.

Material Comparison Table for the Automotive Sector

The following table compares the key metals used in automotive manufacturing based on factors that influence material selection.

|

Material |

Density (g/cm³) |

Strength |

Corrosion Resistance |

Cost |

Common Applications |

|

Steel |

7.8 |

High |

Moderate |

Low |

Chassis, body panels |

|

Aluminium |

2.7 |

Moderate |

High |

Moderate |

Body panels, wheels |

|

Magnesium |

1.74 |

Moderate |

Low |

High |

Transmission cases, wheels |

|

Titanium |

4.5 |

Very high |

Very high |

Very high |

Exhaust systems, springs, valves |

This comparison demonstrates that each material offers specific advantages and limitations. Steel remains the most economical choice for general manufacturing. Aluminium and Magnesium can deliver substantial weight reductions that contribute to improved fuel efficiency and handling. Titanium is recommended for performance-critical applications when weight reduction, strength and corrosion resistance justify its higher cost. For further details, please refer to Stanford Advanced Materials (SAM).

Frequently Asked Questions

What makes Titanium advantageous for automotive applications?

Its strength-to-weight ratio, corrosion resistance and durability make Titanium suitable for lightweight, performance-critical automotive components.

Which automotive metal offers the best corrosion resistance?

Titanium and Aluminium typically provide better corrosion resistance than Steel and Magnesium, particularly under harsh environmental conditions.

Why is Magnesium used in vehicle manufacturing despite its corrosion issues?

Magnesium provides considerable potential for weight saving. Protective coatings are often required to address its corrosion issues.

How does Aluminium compare to Steel in automotive manufacturing?

Aluminium is significantly lighter and more resistant to corrosion than Steel. However, Steel is more stable and less expensive, making it preferable for structural components.

Is Titanium commonly used in all vehicle types?

Titanium is primarily applied in high-performance and luxury vehicles due to its cost. Nevertheless, improvements in manufacturing technology are gradually increasing its use in standard vehicles.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento