5 Common Types Of Catalytic Material

Catalysts are a crucial aspect of achieving higher reaction rates without their own consumption. In industries such as petrochemical refining and pharmaceuticals, the proper selection of catalytic material has a significant impact on efficiency, pricing, and product quality. Herein, five types of catalyst materials will be discussed: precious metals, metal oxides, zeolites, enzymes, and organometallic complexes.

1. Precious Metals

Among the best and widely employed catalysts are valuable metals, including palladium, platinum, rhodium, and gold due to their catalytic activity and stability.

For example, platinum finds widespread application in catalytic converters of motor vehicles to reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Palladium dominates hydrogenation and oxidation reactions, which are important to the chemical and pharmaceutical industries. Rhodium has specialised application in selective hydrogenation, while gold, although less recognised in the past as a catalyst, has emerged as vital in oxidation reactions and environmental catalysis.

2. Metal Oxides

Metal oxides are prominent due to their durability, reasonable costs, and ease of production. Examples include TiO₂, Al₂O₃, and CeO₂.

However, titanium dioxide finds broad applications in environmental uses, such as the photocatalytic degradation of pollutants. In contrast, aluminium oxide plays a more supportive role to metals by increasing their catalytic activity. Cerium oxide has become well known for its ability to store and release oxygen in automotive exhaust treatment and industrial oxidation processes.

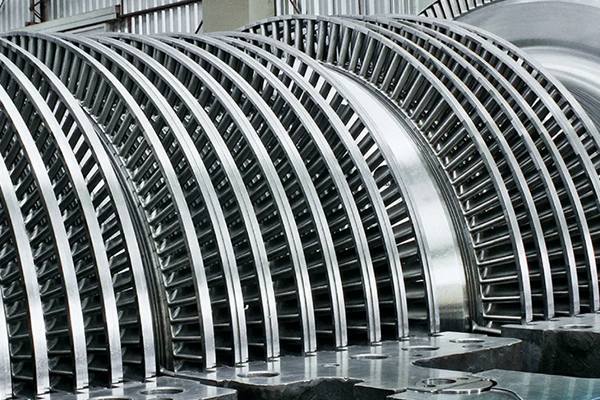

3. Zeolites

Zeolites are crystalline aluminosilicate materials with the characteristic feature of their microporous structures. The latter ensure selectivity in catalytic processes, where only certain molecules of specific sizes and shapes can enter these systems and interact therein. Optimal thermal and pressure stability has made zeolites critically important in the process of petrochemical refining, especially in fluid catalytic cracking, where heavier hydrocarbons are transformed into petrol and other lighter fractions. Furthermore, strong ion-exchange properties make zeolites effectively catalyse wastewater treatment processes.

4. Enzymes

Enzymes, nature's biological catalysts, offer high specificity and efficiency under mild operational conditions. They catalyse biochemical reactions rapidly and selectively with minimal energy input and waste generation. In pharmaceutical synthesis, enzymes catalyse complex transformations with a dramatic improvement in yield and purity. The food industry utilises enzymes in a variety of processes, including fermentation, dairy, and biofuel production. Their environmentally friendly nature significantly contributes to sustainable chemical production.

5. Organometallic Complexes

These are organometallic catalysts, such as metallocenes and transition-metal complexes, which bridge organic and inorganic at molecular levels of precision in catalytic reactions. They show very good flexibility and selectivity in a wide range of synthetic transformations, particularly polymerisation and asymmetric synthesis. These complexes are used on an industrial scale for the manufacture of fine chemicals, pharmaceuticals, and polymers, with well-defined molecular configurations that translate into functional properties.

Materials Comparison Table for Catalyst Field

The following table compares some common catalytic materials in terms of key properties, advantages, and typical applications:

|

Catalyst Type |

Key Properties |

Advantages |

Typical Applications |

|

Precious Metals |

High activity, durability, stability |

Excellent performance, reusable |

Automotive, chemical manufacturing |

|

Metal Oxides |

High surface area, stability |

Economical, robust |

Petrochemicals, pollution control |

|

Zeolites |

Porous structure, shape selectivity |

High selectivity, thermal stability |

Petroleum refining, wastewater treatment |

|

Enzymes |

Biological specificity, mild conditions |

Highly selective, eco-friendly |

Pharmaceuticals, food processing |

|

Organometallic Complexes |

Tunable electronic properties |

Precise control, versatile |

Polymerisation, fine chemical synthesis |

For more information, please visit Stanford Advanced Materials (SAM).

Frequently Asked Questions

What are the advantages of using precious metal catalysts?

The desirable catalytic action of precious metals includes high thermal stability and longevity of the catalyst for application in automotive and industrial chemical reactions.

Why are zeolites preferred in petrochemical refining?

These zeolites possess excellent thermal stability, selective porosity, and shape selectivity that enhance reaction efficiency and product specificity in refining processes.

How do enzymes differ from traditional chemical catalysts?

Enzymes work under mild conditions, with high selectivity and minimal side reactions, and significantly contribute to environmental sustainability.

What makes organometallic complexes versatile catalysts?

Their tunable electronic properties enable specific reaction control, hence their versatility in synthetic processes including polymerisation and fine chemical syntheses.

Are metal oxide catalysts economical in large-scale use?

Yes, certain metal oxide catalysts, such as aluminium oxide and titanium dioxide, are inexpensive, durable, and therefore suitable for large-scale industrial use, including pollution control.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

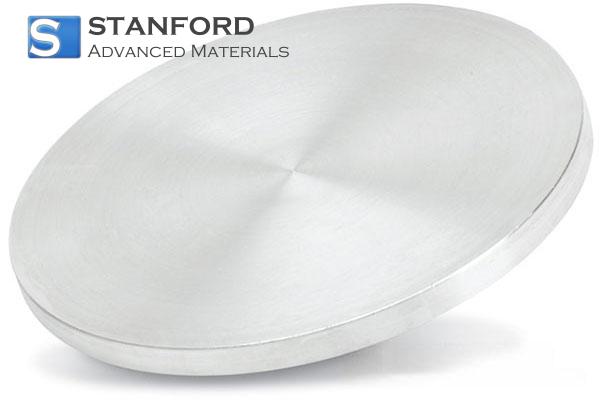

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento