How Metallic Sputtering Targets Power Modern Data Storage

The Role of Metallic Coatings in Data Storage Devices

Modern data storage devices depend on thin metal films to ensure secure and rapid access to data. In many storage devices, thin-film coatings improve data density, operational speed and longevity. Older deposition methods do not meet current performance levels. Storage systems utilise these metal films to write and read data with precision. Thin films support high-frequency electronic switching required for fast operations and contribute to consistent performance over extended usage. The use of metal films satisfies mechanical and electronic integrity requirements, thereby preventing data loss.

Precision Coating in Optical Drives

Optical media such as Compact Discs (CDs), Digital Versatile Discs (DVDs) and Blu-ray Discs require a thin, uniform metal coating. Sputtering processes produce these films from silver alloys, aluminium and indium. These metals provide high reflectivity and deliver consistent signals during data reading. The coating process also enhances thermal resistance; consequently, the media withstand temperature variations without compromising data integrity. Optical drives depend on this precise coating process to maintain reliable performance over time.

Sputtering Targets in Magnetic Media

Hard disk drives utilise sputtering targets to form the layers necessary for data read/write operations. In these devices, cobalt-based and chromium-based alloys are used to achieve the required magnetic properties. The sputtering process controls the alignment of particles in the film. This control defines both the coercivity—which specifies the minimum magnetic field strength needed to change stored data—and the bit density, which indicates the amount of data per unit area. Surface smoothness and film purity at the nanometre scale are critical; if roughness occurs, data reading errors may increase. Consequently, careful process control results in a film that meets high-density storage specifications.

Common Metallic Targets in Data Storage

Several metals are essential in modern data storage. Cobalt-chromium alloys are selected for their magnetic properties and durability. Tantalum is used for its resistance to wear under severe conditions. Nickel and platinum are also incorporated because of their stability and conductivity in various storage applications. Each metal is subjected to stringent testing to determine its suitability for high-speed operations in dense data environments. The precise composition of the film affects its structural characteristics and long-term performance. Engineers choose the appropriate metal mixture based on scientific analysis and empirical testing, with data security remaining the primary priority.

The Future of Coating Technology for Data Storage

Further research is expected to result in significant changes to thin-film deposition in storage devices. Research conducted at institutions such as Stanford Advanced Materials (SAM) and collaborations with Oceania International LLC have identified potential improvements in both optical and magnetic media. New metal alloys may increase performance efficiency. One focus area is the precision of the deposition process. As devices become smaller, coating uniformity must improve accordingly. Advances in sputtering techniques could yield films with enhanced control over composition. Emerging applications, including quantum data storage and drives with ultra-high density, impose additional requirements. Consequently, coatings for these systems must meet specific atomic-scale standards. Researchers and engineers continue to refine these methods to address increased data storage demands.

Conclusion

Modern data storage relies on precise metallic coatings. Sputtering targets are employed to produce layers that allow data to be securely written and read in both optical and magnetic systems. Key materials such as silver alloys, aluminium, indium and cobalt- or chromium-based alloys are effective in managing the performance of read/write operations. These methods result in uniform films capable of operating at high speeds and accommodating dense data storage. Ongoing research and systematic testing are expected to further enhance storage performance.

Frequently Asked Questions

Q: Why are thin films important for data storage?

A: Thin films increase the density, speed and durability of storage devices.

Q: How do sputtering targets assist in hard disk drives?

A: They produce uniform read/write layers that control magnetic properties and bit density.

Q: Which metals are most commonly used in optical drives?

A: Common metals include silver alloys, aluminium and indium.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

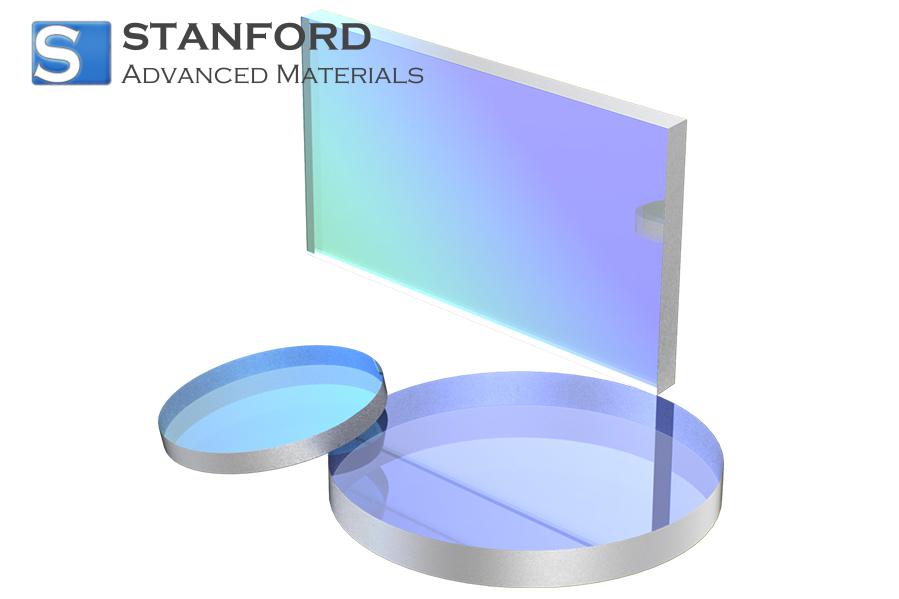

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento