Iron: Element Properties And Uses

What Is Iron?

--Iron the Element

Iron (Fe) is the most common and widespread element on Earth, forming the basis of human technological advancement. Iron is a transition element primarily found in minerals such as hematite (Fe₂O₃) and magnetite (Fe₃O₄) in the Earth's crust. In addition to industrial applications, iron is vital for living organisms as it plays a fundamental role in biological processes. In humans, for example, it is a key component of haemoglobin, the red blood cell protein used in oxygen transport. Iron's dual significance—biological and technical—contributes to its status as one of the most valuable elements known to humanity.

--Iron Metals and Alloys

Iron alloys and metals form the foundation of modern industrial and engineering design. Pure iron is highly ductile and soft, but when combined with other elements, it becomes stronger, more durable, and resistant to wear and corrosion. The two main categories are steel and cast iron, each exhibiting distinct properties and applications.

History of Iron

Iron has been a crucial element throughout human history. The Iron Age, which began around 1200 BCE, marked a period when people transitioned from bronze to tools and weapons made of iron, significantly impacting agriculture, warfare, and construction. Over centuries, refining processes, such as smelting and alloying, enabled improved control over iron, leading to the wide variety of iron-based metals and alloys utilised today.

Properties of Iron Alloys and Metals

--Chemical Properties Description

Chemically, iron is highly reactive, especially with oxygen, resulting in the formation of iron oxides, commonly referred to as rust. Rusting presents a significant problem for the use and maintenance of iron-based products. Iron typically has two stable oxidation states: +2 (ferrous) and +3 (ferric). These oxidation states are essential for most chemical reactions, such as when it reacts with acids.

For instance, when iron interacts with hydrochloric acid, it produces iron chloride and hydrogen gas. At elevated temperatures, iron reacts with carbon to create steel, which is fundamental for modern construction and manufacturing. Pure iron has lower reactivity than its alloys, but environmental conditions and the presence of impurities can greatly affect its chemical properties.

--Physical Properties Data Table

|

Property |

Value |

|

Atomic Number |

26 |

|

Atomic Mass |

55.845 u |

|

Density |

7.87 g/cm³ |

|

1,538 °C |

|

|

Boiling Point |

2,862 °C |

|

Appearance |

Metallic grey or silver |

|

Electrical Conductivity |

Moderate |

|

Magnetic Properties |

Magnetic |

For more information, please check Stanford Advanced Materials (SAM).

Steelmaking and Other Common Uses of Iron

Iron's primary industrial application is in the production of steel, the most prevalent metal used in construction, transportation, and machinery. Steel combines iron's hardness and strength with ductility and can be employed for structural components such as beams, rods, and plates. Cast iron is also a key product, valued for thermal conductivity and compressive strength. Cast iron is used in engine blocks, pipes, cookware, and heavy machinery.

Iron is also biologically significant. It is a vital component of haemoglobin and myoglobin, blood and muscle proteins responsible for oxygen delivery. Without iron, humans and other organisms may develop conditions such as anaemia, which impairs oxygen transport and energy production.

Preparation Methods

The industrial production of iron typically commences with iron ore, which is extracted and purified through smelting. The smelting process involves the use of coke (carbon) and limestone in a blast furnace. High temperatures separate iron ore from impurities, yielding molten iron. This can be further purified or combined to create steel or other iron compounds.

Direct reduction methods have gained popularity in recent years as more environmentally friendly alternatives. These methods utilize hydrogen or other reducing agents to extract iron from ore, resulting in lower carbon emissions compared to smelting.

Frequently Asked Questions

What is the primary industrial usage of iron?

The majority of iron is directed towards steel production, valued for its strength, flexibility, and reliability in construction, transportation, and manufacturing.

How does cast iron differ from steel?

Cast iron contains a higher carbon content, making it brittle but suitable for compression applications and heat retention. Steel is stronger and more durable, allowing for a broader range of structural and mechanical uses.

What are the environmental issues related to producing iron?

The traditional smelting process generates CO₂ emissions and waste. New methods, such as direct reduction with hydrogen, reduce environmental impacts.

How does iron function in the human body?

Iron is essential for the production of haemoglobin, which transports oxygen in red blood cells. Adequate iron intake is necessary for maintaining healthy blood and preventing anaemia.

Bars

Bars

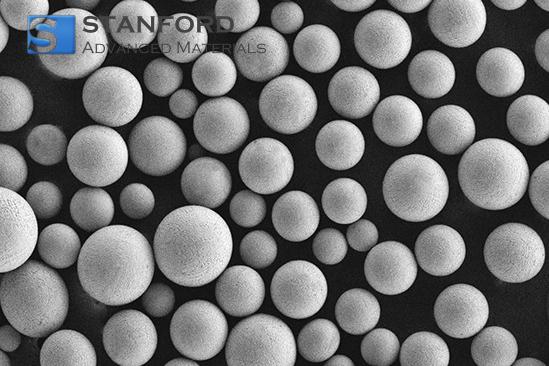

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento