Nickel: Element Properties And Uses

Nickel is a versatile, corrosion-resistant metal widely used in industries such as aerospace, energy, and manufacturing due to its excellent mechanical properties and ability to form durable alloys.

Introduction to an Element

Nickel (Ni), which has an atomic number of 28, is a transition metal element, classified by its silver-white colour and its strong resistance to corrosion and oxidation. Nickel is found naturally in certain minerals, including pentlandite, garnierite, and laterite. Though it is not a common metal in the earth's crust, it is highly prized for its ability to produce a strong and corrosion-resistant metal alloy, particularly in the production of stainless steel. Nickel was discovered in 1751 by Axel Fredrik Cronstedt, a Swedish chemist.

Chemical Properties Description

Nickel is quite stable. This is due to the formation of a protective layer of oxide over the surface of the metal. This makes it very useful in the presence of corrosive materials. The main chemical properties of the metal are:

- Catalytic Property: The resistance of nickel to acids and bases makes it useful in severe environment conditions.

- Acidity and Alkalinity: When it reacts with acids and bases, it forms soluble salts, which makes it useful in several industrial applications.

- Alloying: Nickel is used as an important component in many alloys like stainless steel, nichrome, and Monel, adding excellent mechanical properties, heat stability, and corrosion resistance to them.

Physical Properties Data Table

Here is a table summarising the physical properties of nickel:

|

Property |

Value |

|

Atomic Number |

28 |

|

Atomic Weight |

58.6934 u |

|

1455°C |

|

|

Boiling Point |

2913°C |

|

Density |

8.908 g/cm³ |

|

Electrical Conductivity |

1.43 × 10⁶ S/m |

|

Colour |

Silvery-white |

|

Hardness (Vickers) |

400 HV |

Nickel is a hard and ductile metal that is a good conductor of electricity. Its high melting point and resistance to corrosion make it suitable for high-temperature applications. For more information, please check Stanford Advanced Materials (SAM).

Common Uses

Its desirable properties like high strength, malleability, and corrosion resistance make it an essential material in many industries. Below is an explanation of its applications.

Stainless Steel Manufacture

Nickel is a very important element in the production of stainless steel, in which it generally constitutes 8-12% of the total material. The presence of the element significantly increases the corrosion resistance, strength, and durability of steel, thus offering a valuable application in high corrosion conditions, for example, in kitchen utensils, chemical factories, and buildings. The rust and stain-resistance properties of stainless steel can primarily be attributed to the presence of nickel in utensils, sink units, and medical equipment.

Batteries

Nickel has applications in the production of rechargeable batteries, especially in the production of Ni-Cd and NiMH rechargeable batteries. The Ni-Cd battery, for instance, contains nickel and cadmium as the main materials, while the NiMH battery consists of nickel, metal hydride, and some other materials. Nickel metal hydride battery applications include power tools, HEV cars, and portable electronics. Additionally, nickel applications are involved in the production of stainless steel and some alloys.

Coinage

Nickel was widely used in coinage for many centuries, particularly in alloys of copper and nickel. Nickel coins (5 pence, or the UK nickel) are designed using nickel, mainly for their corrosion resistance and metallic appearance. Nickel coins are long-lasting since they do not wear out or corrode when in use for several decades.

Alloys

Nickel has widespread uses in different high-performance alloys because of its ability to enhance strength, malleability, heat resistance, and corrosion resistance. Some examples of alloys that contain nickel are:

- Nichrome: A high resistance alloy utilised in heating elements for toasters, industrial furnaces, and kilns.

- Monel: This is an alloy that is mainly composed of nickel and copper. Monel is quite resistant to the corrosive action of sea water and hence is used in certain chemical processes as well as in the aerospace industry.

- Inconel: A group of high temperature alloys used in jet engines, gas turbines, and reactors.

The application of nickel in alloys is one of the core sectors for industries requiring a strong, long-lasting, and corrosion-resistant product.

Preparation Methods

Nickel is obtained from its ores by two different processes:

1. Pyrometallurgical Process: This process combines the heating of nickel ores inside a furnace to extract nickel from other elements. Smelting and refining are done to yield nickel matte. Further processing of the product gives pure nickel.

2. Hydrometallurgical Process: Nickel ores are processed with an application of acidic and/or basic solutions to dissolve nickel with the help of the leaching process. Nickel is then refined through electrolytic refining to obtain highly pure nickel.

Such processes make nickel extraction possible from its ores, and the resulting nickel can be used for various purposes.

Related Industrial Products

The versatility of nickel makes it irreplaceable in various sectors. Some industrial applications of nickel include:

- Stainless Steel: employed in the automotive industry, construction sector, and preparation of kitchen utensils.

- Catalysts: Nickel is used in catalysing reactions involving hydrogenation in the chemical industry to turn unsaturated fats to saturated fats.

- Plating: Nickel is largely used in electroplating to cover other metals. This process gives a corrosion-resistance coating to articles like bicycles, watches, and electronic devices.

Nickel's presence in these products underscores its importance in improving the performance and longevity of materials and equipment across multiple sectors.

Frequently Asked Questions

1. What are the main uses of nickel?

Nickel is primarily used in the production of stainless steel, batteries, coinage, and various alloys. It is valued for its strength, corrosion resistance, and ability to store energy in rechargeable batteries.

2. How is nickel extracted from its ores?

Nickel is extracted using pyrometallurgical methods (heating and smelting) or hydrometallurgical methods (leaching with acids or alkaline solutions), followed by electrolytic refining to produce pure nickel.

3. What are the physical properties of nickel?

Nickel is a ductile, hard metal with a high melting point (1455°C), high density (8.908 g/cm³), and good electrical conductivity (1.43 × 10⁶ S/m).

4. Why is nickel used in stainless steel?

Nickel enhances the strength, corrosion resistance, and durability of stainless steel, making it ideal for use in industries like construction, automotive, and kitchenware.

5. How does nickel contribute to the performance of batteries?

Nickel is crucial in rechargeable batteries due to its high energy density and long cycle life, contributing to the performance of hybrid vehicles and power tools.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

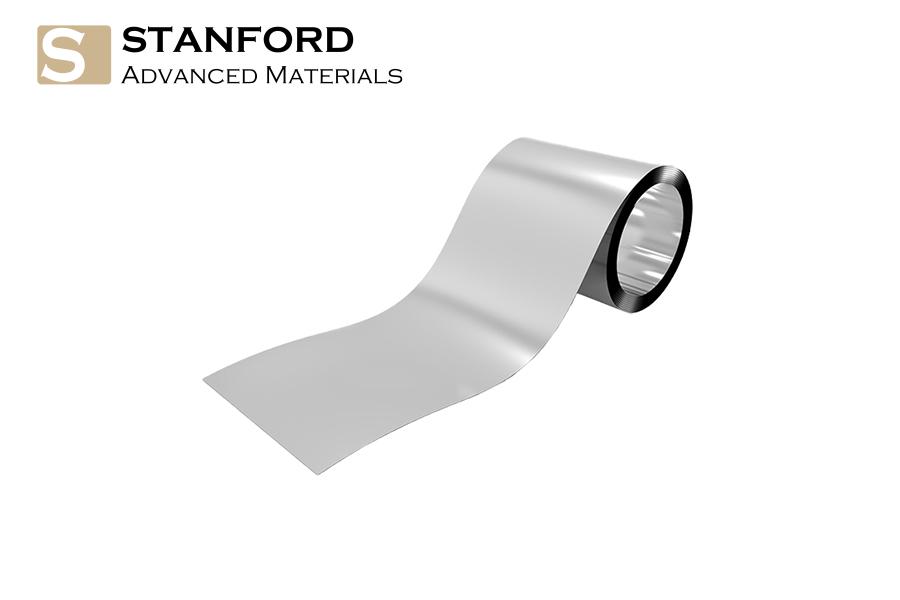

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento