Surprising Facts About Ceramics You Didn't Know

Ceramics are widely used in various applications—from domestic pottery to advanced aerospace components. Although many individuals associate ceramics with fragile dishes or tiles, these materials possess significant properties that extend beyond common perceptions. Here are ten facts about ceramics that may alter your understanding of them.

10 Surprising Facts About Ceramics

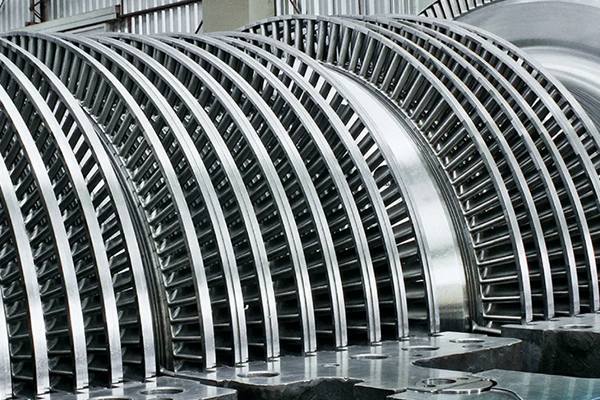

- They can withstand high temperatures. Certain ceramics do not melt even at temperatures exceeding 2,000°C (3,600°F). This characteristic makes ceramics crucial in satellite and jet engine applications.

- They can be harder than steel in specific contexts. Silicon carbide and boron carbide rank among materials that exceed the hardness of steel. They approach the hardness of diamonds, though not quite at that level.

- Lightweight protective armour. The development of advanced ceramics utilising alumina and boron carbide allows for lightweight body armour that effectively deflects bullets while minimising weight.

- Biomedical implants are compatible with the body. Zirconia ceramic and hydroxyapatite ceramic have been used for dental crowns, joint replacements, and bone transplants due to their compatibility and hardness.

- There are transparent varieties. Certain transparent ceramics, such as aluminium oxynitride (ALON), exhibit strength superior to glass, rendering them suitable for use in armoured windows and advanced optical systems.

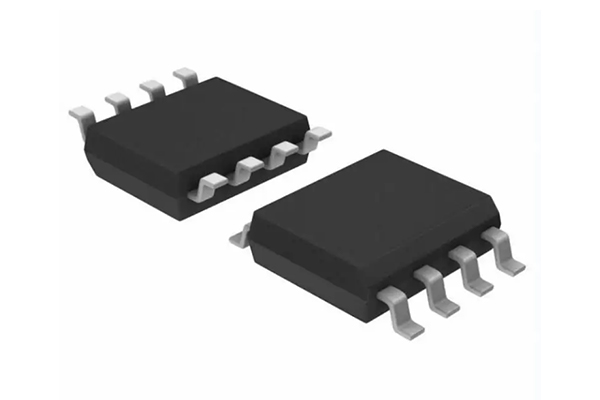

- They are components in electronics. Devices within your smartphone, computer, and television employ ceramic components such as capacitors, semiconductors, and insulators because of their high electrical resistance.

- They rank among the oldest known man-made materials. Ceramics have been manufactured by humans for over 10,000 years, ranging from pottery to writing surfaces.

- These materials can be engineered for greater hardness. While ceramics are often fragile, engineered ceramics can achieve impact resistance, thereby finding use in aerospace and military applications.

- They play a role in reducing pollution. Ceramic filters can purify water and air, and in automotive applications, catalytic converters utilise ceramics to lower emissions.

- Some possess self-repairing capabilities. Researchers are investigating self-healing materials capable of repairing microscopic cracks in ceramics, which could have applications in aviation.

Note: The explanation provided elaborates on the advantages of each ceramic material in specific contexts. For further information, you may visit Stanford Advanced Materials (SAM).

Advanced Ceramics: Alumina, Zirconia, and Other Varieties

Alumina

Alumina, or aluminium oxide, is a widely recognised term in the realm of advanced ceramics. This compound is esteemed for its hardness, wear resistance, and electrical insulation properties. It withstands high temperatures and is frequently employed in the manufacturing of components for furnaces and other refractory materials. In the electronics sector, it serves as a stable substrate for the fabrication of integrated circuits. Its biocompatibility has also made it a choice material for medical implants.

Zirconia

Zirconia, often referred to as "ceramic steel," possesses desirable attributes including strength, ductility, and resistance to breakage. Although non-biodegradable and relatively costly, zirconia is critical in applications as structural ceramics, dental crowns, and hip joints that endure cyclic stresses and maintain structural integrity under continuous loads.

Boron Nitride

Boron nitride exhibits high thermal conductivity alongside superior electrical insulation, earning it the moniker "white graphite." It displays remarkable resistance to oxidation up to 1,000°C. In high-temperature applications, it acts as a lubricant and release agent in processes such as metalworking and glassmaking.

Boron Carbide

Boron carbide ranks among the hardest known materials, justifying its use in armour plating, bullet-resistant vests, and vehicle armour. Its relative lightness, combined with its hardness, also positions it as a vital compound in abrasive blasting and cutting tools.

Frequently Asked Questions

What are the reasons for the use of ceramics in medical implants?

Ceramics such as alumina and zirconia are biocompatible, corrosion-resistant, and non-abrasive, making them suitable for use in implants.

Are all ceramics brittle?

Conventional ceramics are inherently brittle; however, modern engineered ceramics, particularly zirconia, are formulated to exhibit improved toughness and decreased brittleness.

How does Boron Nitride differ from Graphite?

Boron nitride serves as an excellent electrical insulator, in contrast to graphite. It maintains similar levels of lubricity and thermal conductivity.

Why is Boron Carbide favoured for armour production?

Its properties of exceptional hardness and ballistic resistance enable effective shock energy absorption and dissipation.

Do ceramics conduct electricity?

Ceramics typically act as insulators, though certain conductive oxides can conduct electricity effectively.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento