The Strongest, Lightest, And Most Expensive Metals You Didn't Know About

Description

Metals are indispensable components in various sectors, including aerospace and medical implant production. While common metals such as steel, aluminium and gold are prevalent, some less frequently discussed metals can be quantified by high tensile strength, low density or elevated cost. The following section presents data on several of these metals.

--Strongest Metals

1.tungsten (W)

- Tungsten has the highest tensile strength among naturally occurring metals and a melting point of 3 422 °C (6 192 °F).

- Uses: Military applications; industrial tooling; aerospace engineering.

- Disadvantage: In its pure state, tungsten is brittle; however, tungsten alloys enhance its usability.

2.titanium (Ti)

- Titanium exhibits a favourable strength-to-weight ratio and is resistant to corrosion.

- Applications: Aerospace; medical implants; high-performance vehicles.

- Disadvantage: It is challenging to machine; consequently, it is expensive.

3.chromium (Cr)

- Chromium is hard and wear-resistant, which contributes to its use in the production of stainless steel.

- Applications: Coating processes; stainless steel manufacturing; corrosion-resistant finishes.

- Disadvantage: In its pure form, it is brittle and requires alloying to improve performance.

-The Lightest Metals

1)Lithium (Li)

- Lithium is the metal with the lowest density and weighs approximately half as much as water.

- Applications: Batteries; aerospace; pharmaceutical formulations.

- Disadvantage: It is highly reactive and requires specialised handling.

2.magnesium (Mg)

- Magnesium is 33% lighter than aluminium and provides adequate strength.

- Applications: Automotive and aerospace sectors, where weight reduction improves fuel efficiency.

- Disadvantage: In powdered form, it is highly flammable.

3.beryllium (Be)

- Beryllium is lighter than aluminium and considerably stronger.

- Applications: Spacecraft; satellites; advanced optical devices.

- Disadvantage: It is toxic when inhaled, necessitating strict safety measures.

--The Costliest Metals

1.rhodium (rh) - ~ $10 000 per ounce

- Rhodium is rare and highly resistant to corrosion. It is used in catalysts.

- Applications: Automotive industry; jewellery; electrical contacts.

2.platinum (Pt) - ~ $1 000 per ounce

- Platinum is rarer than gold and demonstrates resistance to tarnishing and corrosion.

- Applications: Jewellery; medical implants; catalysts.

3.osmium (Os) - ~ $1 200 per ounce

- Osmium is the densest naturally occurring metal and is exceptionally rare.

- Applications: Fountain pen tips; electrical connectors; specialised scientific instruments.

Precious Metals

Precious metals are identified by their scarcity, aesthetic properties, corrosion resistance and high economic value. Gold is extensively employed in jewellery, electronics and dentistry, while platinum and palladium are utilised in catalysts and electronic manufacturing. Rhodium, the rarest amongst them, is applied for coating optical instruments, jewellery and catalysts.

Despite their recognised appearance, precious metals are also used for their thermal stability and electrical conductivity in industrial applications. Their high economic value is due to their scarcity and the considerable energy required for extraction and refining.

Refractory Metals

Refractory metals are defined by their high melting points, hardness and resistance to wear and corrosion. Typical refractory metals include tungsten, molybdenum, tantalum, niobium and rhenium. Tungsten, with a melting point of 3 422 °C, is used in incandescent lamp filaments, X-ray tubes and aerospace engineering.

Tantalum and niobium exhibit excellent chemical resistance and are used in capacitors and electronic components. Molybdenum maintains strength at high temperatures and is employed in engine alloys and structural components in aerospace. Rhenium, being rare and highly heat-resistant, is used to increase the durability of turbine blades in jet engines.

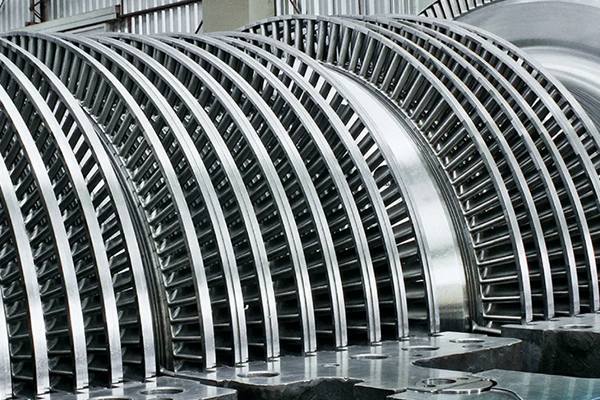

Superalloys

Superalloys are high-performance metals engineered to withstand extreme mechanical stresses, high temperatures and corrosion. They are typically composed of nickel-, cobalt- and iron-based alloys and are critical to aerospace, power generation and medical implant sectors. Nickel-based superalloys, such as Inconel, exhibit excellent heat resistance, strength and oxidation resistance and are used in gas turbine engines and exhaust systems.

Cobalt-based alloys, including Stellite, have a high resistance to wear; consequently, they are used in surgical implants and cutting tools. Iron-based superalloys are heavier but provide a favourable strength-to-weight ratio and are utilised in the automotive, aerospace and industrial sectors.

Frequently Asked Questions

Which metal has the best strength-to-weight ratio?

Titanium has the highest strength-to-weight ratio among the metals. It is used in aerospace, medical implants and high-performance vehicles.

Which is the lightest metal used in industry?

Lithium is the lightest metal and is employed in batteries, aerospace and pharmaceuticals due to its low density and high energy storage capacity.

Why is rhodium so expensive?

Rhodium is one of the rarest metals and is mainly obtained as a by-product during platinum extraction. Its usage in catalysts contributes substantially to its cost.

Are light metals as strong as heavier metals?

Certain light metals, such as titanium and beryllium, exhibit high strength despite their low density. They are suitable for demanding applications in aerospace and defence.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

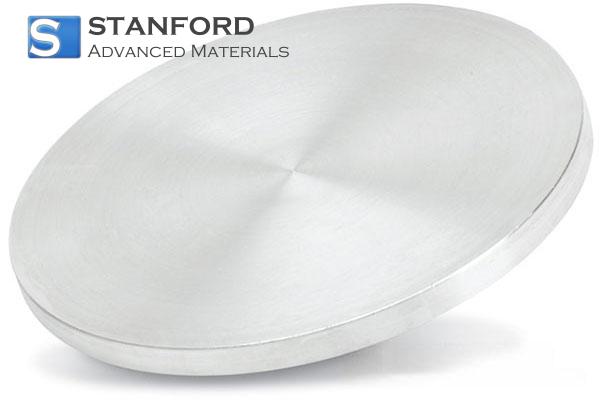

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento