Common Types Of Advanced Ceramics

Description

Advanced ceramics, or engineered ceramics, display superior mechanical properties, thermal stability, and chemical resistance compared to traditional ceramics. Key examples of advanced ceramics include Alumina (Aluminium Oxide), Zirconia (Zirconium Oxide), Aluminium Nitride, Boron Nitride, Silicon Nitride, Silicon Carbide, and Boron Carbide. Each of these materials provides specialised solutions for demanding industrial conditions due to their distinct characteristics.

Types of Advanced Ceramics

1. Oxide Ceramics

- Alumina (Al₂O₃):

From all the advanced ceramics, alumina, or aluminium oxide, is one of the most commonly used and cost-effective options. Renowned for its remarkable hardness, excellent wear resistance, and outstanding electrical insulation, it finds extensive application in electronic substrates, mechanical seals, biomedical implants, and cutting tools. Its thermal stability and ability to withstand high temperatures make it an ideal material for semiconductor manufacturing, where high dielectric strength along with mechanical robustness is needed.

- Zirconia (ZrO₂):

Zirconia boasts excellent toughness, fracture resistance, and high strength. It is often termed "ceramic steel" due to its unique property of impeding crack propagation and impact stress. In various applications, including dental implants, high-performance bearings, cutting instruments, and wear parts, zirconia has been widely used. Because of its biocompatibility and aesthetic quality, zirconia is particularly favoured for medical implants and jewellery.

2. Non-Oxide Ceramics

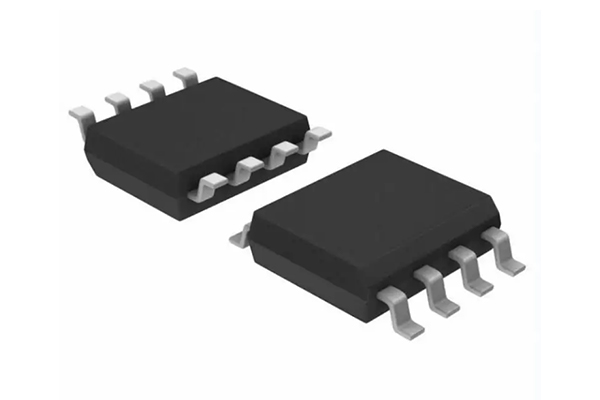

- Aluminium Nitride (AlN):

Aluminium nitride is a material with high thermal conductivity, combined with excellent electrical insulation. It is also highly important in high-performance electronics because of its application in thermal management, such as heat sinks, substrates for power electronics, and optical components. Its ability to efficiently dissipate heat while providing electrical insulation makes it indispensable in semiconductors.

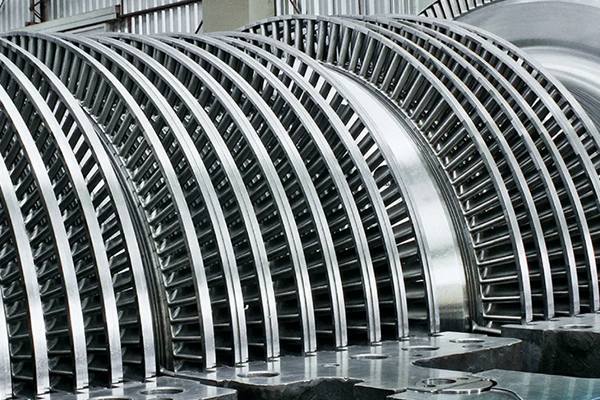

- Silicon Nitride (Si₃N₄)

Silicon nitride has excellent hardness, wear resistance, and thermal shock resistance. It is used extensively in aerospace and mechanical parts, in engine components, as a material for cutting tools, and in high-performance bearings due to the extreme mechanical and thermal stresses endured by the material. Its durability under high-temperature conditions makes it ideal for turbine engines and other high-heat applications.

- Silicon Carbide (SiC):

Among the hardest materials known, silicon carbide is characterised by extreme thermal conductivity, strength, and resistance to abrasion. This material is utilised in abrasive materials, cutting tools, heat exchangers, and semiconductor devices. The high thermal stability and strength of silicon carbide make it suitable for application in automotive brake parts and ceramic armour used in military sectors.

- Boron Nitride (BN):

In addition to the thermal conductivity and lubricating properties of graphite, boron nitride is an electrical insulator. Boron nitride comes in two forms. Hexagonal boron nitride, hBN, has a structure similar to graphite and, like graphite, is an electrical insulator. Cubic boron nitride, cBN, is the second hardest material, after diamond, used in cutting tools and grinding wheels in machining hardened metals and alloys. The hBN is used in high-temperature lubricants, as a thermal insulator and in abrasive applications.

- Boron Carbide (B₄C):

Boron carbide is one of the hardest materials known, with its hardness ranking only after diamond and cubic boron nitride. Boron carbide exhibits excellent hardness, low density, high chemical resistance, and neutron absorption. As a result, boron carbide has considerable uses in defence-related areas, namely in lightweight armour plating of military vehicles and personal body armour. Its neutron-absorbing properties are handy in nuclear reactors, both for control rods and shielding. Extensive applications involve abrasive materials, cutting tools, and polishing agents.

Property and Use Data Table

The following table summarises the key properties and common uses of the discussed ceramic materials.

|

Ceramic Material |

Key Properties |

Common Applications |

|

Alumina (Al₂O₃) |

High hardness, excellent wear resistance, outstanding electrical insulation |

Electronic substrates, mechanical seals, biomedical implants |

|

Zirconia (ZrO₂) |

Exceptional toughness, crack resistance, high strength, biocompatibility |

Dental implants, bearings, cutting tools, wear-resistant components |

|

Aluminium Nitride (AlN) |

High thermal conductivity, excellent electrical insulation |

Heat sinks, semiconductor substrates, optical components |

|

Silicon Nitride (Si₃N₄) |

High hardness, wear resistance, thermal shock resistance |

Aerospace components, high-temperature engine parts, cutting tools |

|

Silicon Carbide (SiC) |

Extreme hardness, high thermal conductivity, resistance to abrasion |

Abrasive materials, heat exchangers, semiconductor devices |

|

Boron Nitride (BN) |

Thermal conductivity, electrical insulation, lubricity, high hardness (cBN) |

High-temperature lubricants, abrasive tools, cutting tools |

|

Boron Carbide (B₄C) |

Extreme hardness, low density, neutron absorption |

Armour plating, nuclear shielding, abrasives, cutting tools |

For more information, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

1. What is the difference between advanced ceramics and traditional ceramics?

Advanced ceramics are especially engineered for superior mechanical properties, resistance to a wide temperature range, and chemical attack. All these features make them suitable for critical industrial applications, whereas conventional ceramics are normally used in decoration and low-performance applications.

2. Why is zirconia preferred for dental implants?

Zirconia is used in dental implants for its biocompatibility, strength, and fracture toughness, among other aesthetic reasons. Its resemblance to natural teeth and the ability of this material to act as a tooth, combined with its high strength and resistance to crack, make it a perfect material for dental procedures.

3. Can alumina ceramics conduct electricity?

No, alumina ceramics are excellent electrical insulators and find broad applications where electrical insulation is required, from electronic components to substrates.

4. Why does boron carbide make good armour plating?

The extreme hardness, light weight, and penetration resistance make boron carbide an ideal material for providing efficient protection against ballistic threats in both personal body armour and military vehicle armour.

5. Why is boron carbide used in nuclear reactors?

It is used in nuclear reactors due to its neutron-absorbing properties, making it very effective for use as a material in control rods and radiation shielding. This helps in controlling nuclear reactions and protecting sensitive equipment.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento