Top 10 Myths About Aerospace Metals—Debunked!

Description

This guide addresses 10 myths regarding metals in aerospace. It presents data from established research and documented practical experience so that readers may understand the scientific basis of these materials, which are important for modern aerospace.

Myth 1: Aerospace metals are too heavy for flight

It is commonly assumed that metals used in aerospace are inherently heavy and would consequently reduce the speed of aircraft or rockets. In practice, engineers utilise lightweight metal alloys such as aluminium, titanium and high‐performance composite materials. These materials exhibit a high strength-to-density ratio, which is essential for performance-critical aerospace systems.

Myth 2: Aerospace metals are more susceptible to rust and corrosion

A second widely held myth maintains that aircraft metals rust and corrode easily. In practice, aerospace materials are subjected to specific treatments. These materials undergo processes such as anodising, coating and alloying in order to withstand severe environmental conditions. Consequently, they maintain their structural integrity over extended periods under extreme conditions.

Myth 3: Titanium is too expensive for widespread use

Titanium is often criticised for its cost. Although this metal is more expensive than alternatives, its enhanced strength-to-weight ratio and resistance to corrosion justify the expense. Engineers select it primarily for critical structural components where neither performance nor safety may be compromised.

Myth 4: Aerospace metals fail unexpectedly under load

It is generally assumed that aerospace metals fail suddenly and without warning under high loads. In practice, these metals undergo thorough testing and are designed with strict safety factors. Scheduled maintenance and regular inspections allow for the detection of emerging issues before they become hazardous, thereby ensuring predictable performance.

Myth 5: Only a few metals are used in aerospace

In reality, a wide range of metals and alloys is employed in aerospace, including aluminium, titanium, nickel-based superalloys and even rare refractory metals developed for various performance requirements. This variety allows engineers to select the most appropriate material for each aircraft or spacecraft component.

Myth 6: New metal innovations are rare in aerospace

It is a myth that the aerospace industry relies exclusively on traditional metals and seldom adopts new innovations. In fact, research is ongoing into the development of advanced alloys that are lighter, stronger and more durable. Such innovations typically result from collaborations between academic institutions and industry organisations.

Myth 7: Recycling of aerospace metals is inefficient

It is commonly assumed that recycling metals from decommissioned aircraft is either impossible or unfeasible. Recycling processes have advanced significantly. Aluminium and titanium are separated, melted and recycled to produce new aerospace components. These methods reduce waste and production costs.

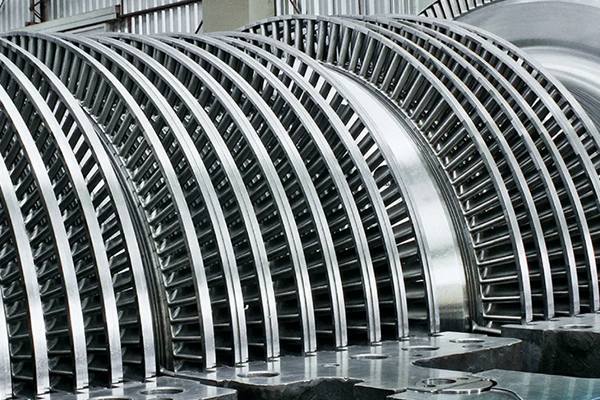

Myth 8: Aerospace metals are important only for the airframe

It is assumed that metals are required only for the external structure of aircraft. In practice, metals are used in every part of an aerospace vehicle – from engines and landing gear to internal systems. Their properties are required for various functions, including heat resistance and the management of stress under operational loads.

Myth 9: Metal failure in aerospace results from inadequate material quality

Another myth is that failures are solely attributable to substandard metals. In practice, such failures usually occur due to a combination of design errors, unexpected operational loads and maintenance issues. Aerospace metals are produced according to stringent manufacturing requirements and testing protocols, thereby ensuring consistent material quality.

Myth 10: The use of new metals in aircraft compromises aviation safety

Some people fear that the utilisation of new metals in aircraft compromises air travel safety. In practice, new metals for aerospace are subjected to careful testing and rigorous quality assessments. They are specifically selected to enhance safety and reliability, and consequently, aviation remains one of the safest modes of transport. For further information, please visit Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: How do aerospace metals differ from common industrial metals?

A: Aerospace metals are specifically developed through alloying and treatments to achieve low weight, a high strength-to-weight ratio and resistance to both corrosion and heat. These properties are essential for functioning under severe conditions.

F: How do engineers decide which metal to use for a specific aircraft component?

A: Engineers consider factors such as load, temperature, stress and environmental influences. They select metals that satisfy these requirements and also take account of cost and availability.

F: Can the recycling of aerospace metals help to reduce environmental impact?

A: Yes, modern recycling processes for metals such as aluminium and titanium are efficient and contribute to reducing waste and lowering the environmental impact of the aerospace industry.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento