What to Know about Cubic Boron Nitride Abrasives

What Is Cubic Boron Nitride?

Cubic boron nitride is a very hard material used in abrasive applications. Many years ago, engineers noted that its hardness rivals that of natural diamond. However, its thermal and chemical stability is better in many circumstances. This makes cubic boron nitride a top choice for cutting, grinding, and polishing.

Comparison of Cubic Boron Nitride with Diamond Abrasives

Both cubic boron nitride and diamond are renowned for their hardness. Diamond abrasives have long been used in stone cutting and other applications. Yet, cubic boron nitride offers distinct advantages. For instance, cubic boron nitride can withstand high temperatures better than diamond. In metal grinding, cubic boron nitride is preferred since diamond tends to wear when exposed to certain metallic elements.

From a cost perspective, diamond abrasives may sometimes be more expensive and may not be ideal for every application. In everyday industrial settings, cubic boron nitride provides a longer life cycle with consistent performance. Experienced engineers appreciate cubic boron nitride for its steady behaviour under harsh conditions. This material has a proven track record in heavy-duty applications.

Further reading: HBN, CBN, and WBN: A Comparative Analysis of Boron Nitride Polymorphs

Types of Cubic Boron Nitride Abrasives

There are several types of cubic boron nitride abrasives designed for different applications. They come in various shapes and sizes. The main types are grinding wheels, powders, micro-grains, and polycrystalline tools.

--Cubic Boron Nitride Grinding Wheels (Bonded and Coated)

Grinding wheels made with cubic boron nitride are among the most common tools in industrial grinding. These wheels come in two forms: bonded and coated.

Bonded grinding wheels use a mixture of cubic boron nitride and a bonding resin or metal. This bond holds the abrasive particles firmly in place. Bonded wheels tend to be durable and are used for more forceful grinding actions.

Coated grinding wheels have a thin layer of cubic boron nitride adhered to their surface. These are used for lighter grinding and finishing. The coating offers precision but wears faster than bonded types. Both types have their merits. An experienced engineer will choose the type based on the materials being worked on and the desired finish.

--Cubic Boron Nitride Powder and Micro-Grains

Cubic boron nitride powders have many uses in surface finishing and fine grinding operations. They are available in different grit sizes. Coarser powders are useful for heavy material removal. Finer powders are excellent for finishing surfaces and polishing.

Micro-grains of cubic boron nitride are even more refined. They have a very small particle size. Manufacturers favour them for detailed work. Fine grinding and precision polishing benefit from the controlled abrasiveness of these micro-grains. The fine grains allow for a smooth finish even on tough metallic surfaces. Their use is common in both automotive and aerospace applications.

Cubic Boron Nitride Synthesis Techniques (High Pressure High Temperature, Chemical Vapor Deposition)

There are two main methods used to synthesise cubic boron nitride: high-pressure high-temperature (HPHT) and chemical vapor deposition (CVD).

The high-pressure high-temperature method mimics the natural formation of diamond and similar substances. This method applies great pressure and temperature to convert hexagonal boron nitride into cubic boron nitride. It produces a strong and high-quality product that is well suited for industrial applications.

The chemical vapor deposition method uses gas-phase chemical reactions. It deposits a thin film of cubic boron nitride on a substrate. This technique is useful for applications where a surface coating is preferred. Both methods have strengths and limitations. The choice often depends on the desired grain size, purity, and the specific application at hand.

Applications of Cubic Boron Nitride Abrasives

Cubic boron nitride abrasives see a wide range of applications in many fields. They are used in grinding tools for hardened steel parts. They are popular in metalworking shops and machine tool operations. Many automotive parts are shaped using these abrasives. Aerospace industries too benefit from their high thermal stability.

In the tool manufacturing process, cubic boron nitride is used to finish surfaces and remove material precisely. In one case, a repair workshop used cubic boron nitride grinding wheels to refine the edges of hardened dies. Industrial plants have used cubic boron nitride powders to achieve a polished finish on high-strength materials.

One common example occurs in the automotive industry. Engine components require precise dimensions and smooth surfaces. Cubic boron nitride tools maintain their hardness and do not wear too quickly even under heavy use. This reliability adds value by reducing downtime and tool replacement needs.

Another real-life case involves the aerospace sector. When working on high-temperature alloys, cubic boron nitride polishing tools offer consistent quality. Their performance under high stress and temperature is well documented. The result is a safer and more efficient machining process.

Conclusion

Cubic boron nitride abrasives stand apart due to their durability and high performance. They are a wise choice in many grinding and polishing tasks. When compared with diamond abrasives, cubic boron nitride offers better thermal stability in certain applications. The variety of products, from grinding wheels to polycrystalline tools, allows for a tailored approach to different manufacturing challenges.

Frequently Asked Questions

Q: What makes cubic boron nitride better than diamond in

metal grinding?

A: Cubic boron nitride handles high temperatures and reacts less with ferrous

metals than diamond.

Q: What are the main types of cubic boron nitride abrasives?

A: They include grinding wheels, powders, micro-grains, and polycrystalline

tools.

Q: What synthesis techniques are used for cubic boron

nitride?

A: High-pressure high-temperature and chemical vapor deposition methods are the

main techniques.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

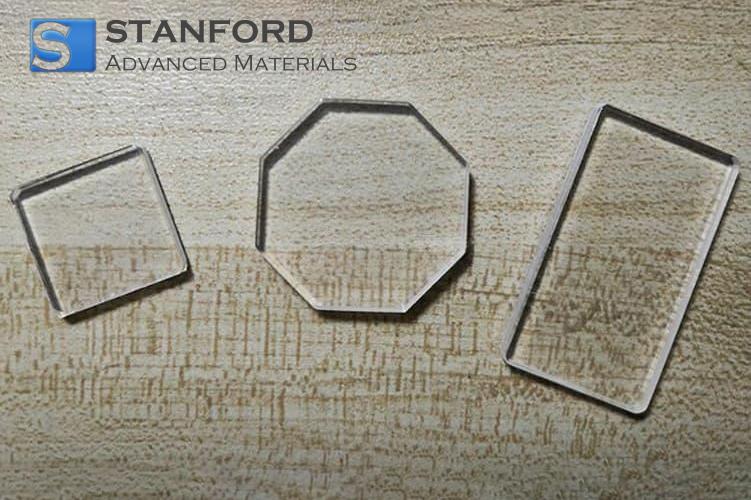

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

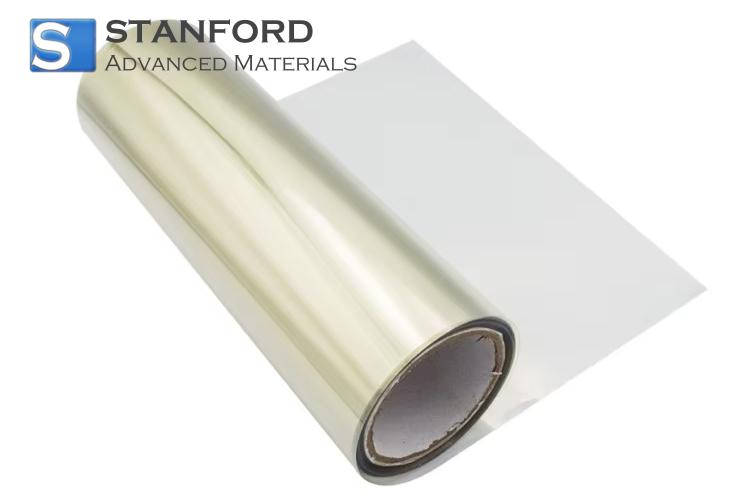

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento