Application Of Titanium Foam

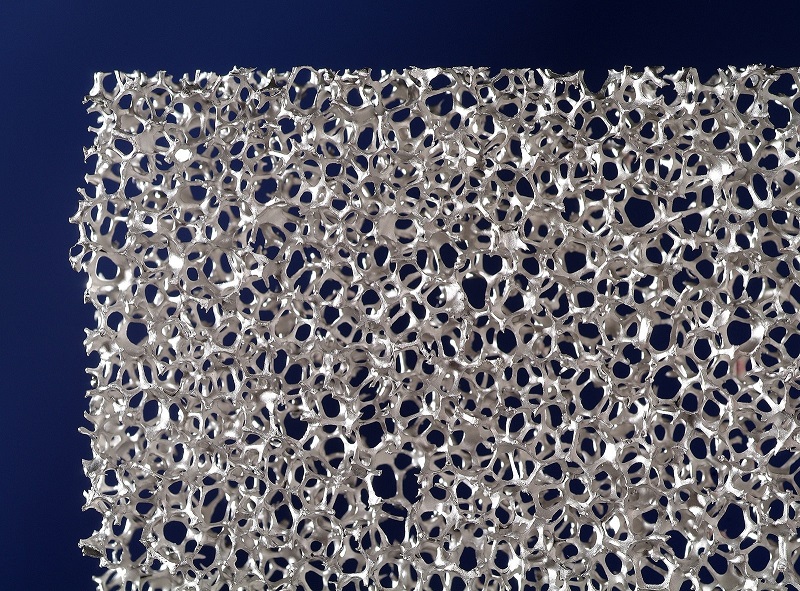

Everyone is familiar with metal, but have you ever heard of metal foam? Metal foam is a new type of metallic material that incorporates foam pores. It maintains the characteristics of metals such as weldability, conductivity and thermal expansion, while providing attributes of porous materials: energy absorption, vibration damping, noise reduction, electromagnetic shielding, air and water permeability and low thermal conductivity. Among the metal foams currently produced are primarily Aluminium-, Magnesium, Copper-, Nickel-, Steel- and Titanium Foams. This article presents a detailed examination of the application of titanium foam.

Application of Titanium Foam

Application of Titanium Foam

1. Application of Titanium Foam in Biomedical Materials

Titanium foam demonstrates biocompatibility, appropriate mechanical characteristics and corrosion resistance inherent to titanium and its alloys. Its interconnected porous structure enables the transport of water and nutrients. Consequently, this structure supports the adhesion, differentiation and proliferation of bone cells, thereby reinforcing the connection between the implant and bone and facilitating biological fixation.

Consequently, porous titanium alloy may be applied as an implant material in the restoration of bones, joints, blood vessels and dentition.

2. Application of Titanium Foam in Impact-Resistant Materials

Under impact, the pores in titanium foam absorb energy and can sustain a greater load. Given that this material withstands high impact, it may be utilised in automotive crash structures, spacecraft chassis, elevator safety buffers, various packaging applications and as a protective material for rocket and turbine engines.

3. Application of Titanium Foam in Battery Materials

The utilisation of porous titanium foam that offers high porosity and a large specific surface area as the gas diffusion layer in fuel cells can significantly enhance the energy released during the electrochemical reaction.

4. Application of Titanium Foam in High-Temperature Dust Filter Materials

Due to the permeability provided by its hollow structure, titanium foam combines high-temperature heat resistance, oxidation resistance and permeability. It may be used for dust filtration under elevated temperature conditions.

Recent investigations into foamed titanium materials have produced quantifiable results. However, the technology remains in an experimental stage and is not yet industrially established. Further in-depth research is required to achieve broader application of titanium foam.

Conclusion

Thank you for reading this article. We trust that it has provided a clearer understanding of the application of titanium foam. If you require further information regarding titanium and titanium foam, please visit Stanford Advanced Materials (SAM) for additional details.

Stanford Advanced Materials (SAM) is a global supplier of titanium foam. It has more than 20 years’ experience in the manufacture and distribution of titanium and titanium foam and provides titanium products that meet the research and production requirements of its clients. SAM is regarded as a dependable supplier and business partner for titanium products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento